MSD

TM

Series

© Copyright 2018 Fluid Equipment Development Company | www.fedco-usa.com

- 45 -

Pump Assembly Continued

15. Install the sheet metal coupling guards.

16. Tighten mounting bolts to “Inlet Housing

Bolts” torque value found in the Fastener

Torque Specications section of this manu-

al.

Figure 85 - Sheet Metal Coupling Guard

Installation

Sag Test

The Sag Test is used to measure the amount

of deection that a dial indicator bracket will un-

dergo at a given distance under its own weight.

This determines the sag tolerance of a given

dial indicator set up.

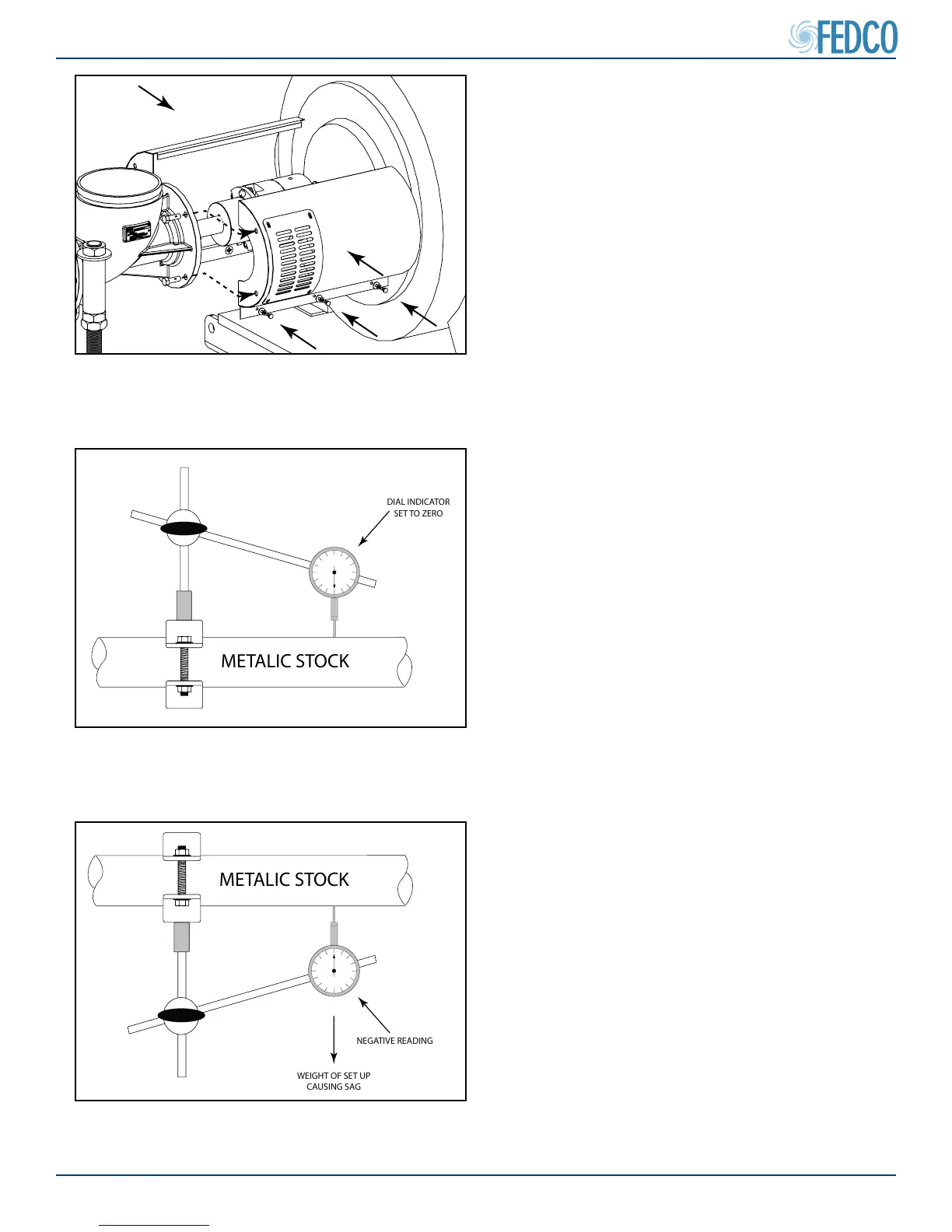

1. Assemble a dial indicator set up similar to

the one which will be used during the align-

ment procedure and place it on a length of

suitable metal stock. Set the indicator to

zero.

Figure 86 - Sag Test Dial Indicator Set Up

METALIC STOCK

DIAL INDICATOR

SET TO ZERO

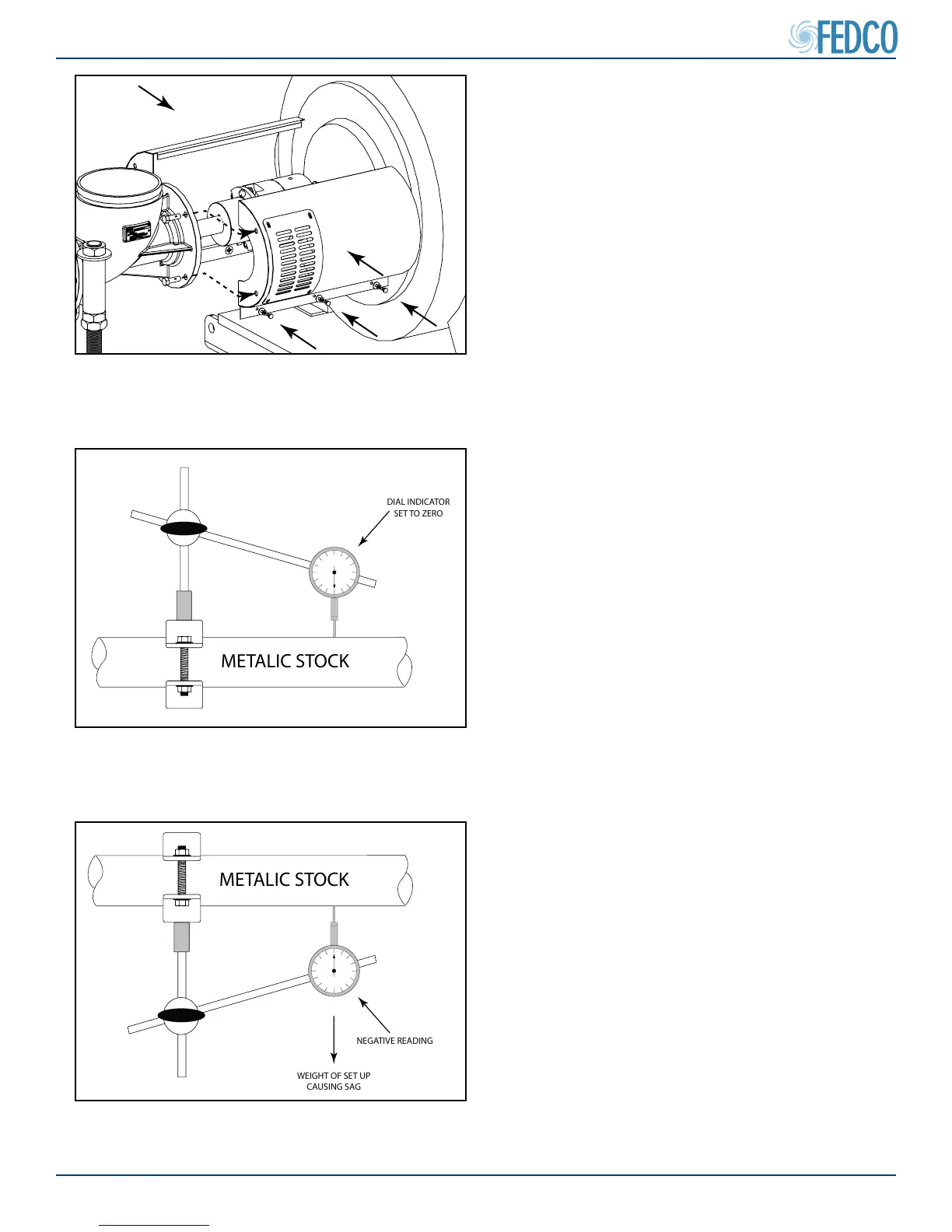

Figure 87 - Recording Sag Test Negative

Indicator Reading

METALIC STOCK

NEGATIVE READING

WEIGHT OF SET UP

CAUSING SAG

2. Without disturbing the indicator set up, invert

the entire set up 180° (turn it upside down).

3. Record the amount of deection measured

on the indicator. It will read as a negative

number.

Loading...

Loading...