MSD

TM

Series

© Copyright 2018 Fluid Equipment Development Company | www.fedco-usa.com

- 46 -

Pump Assembly Continued

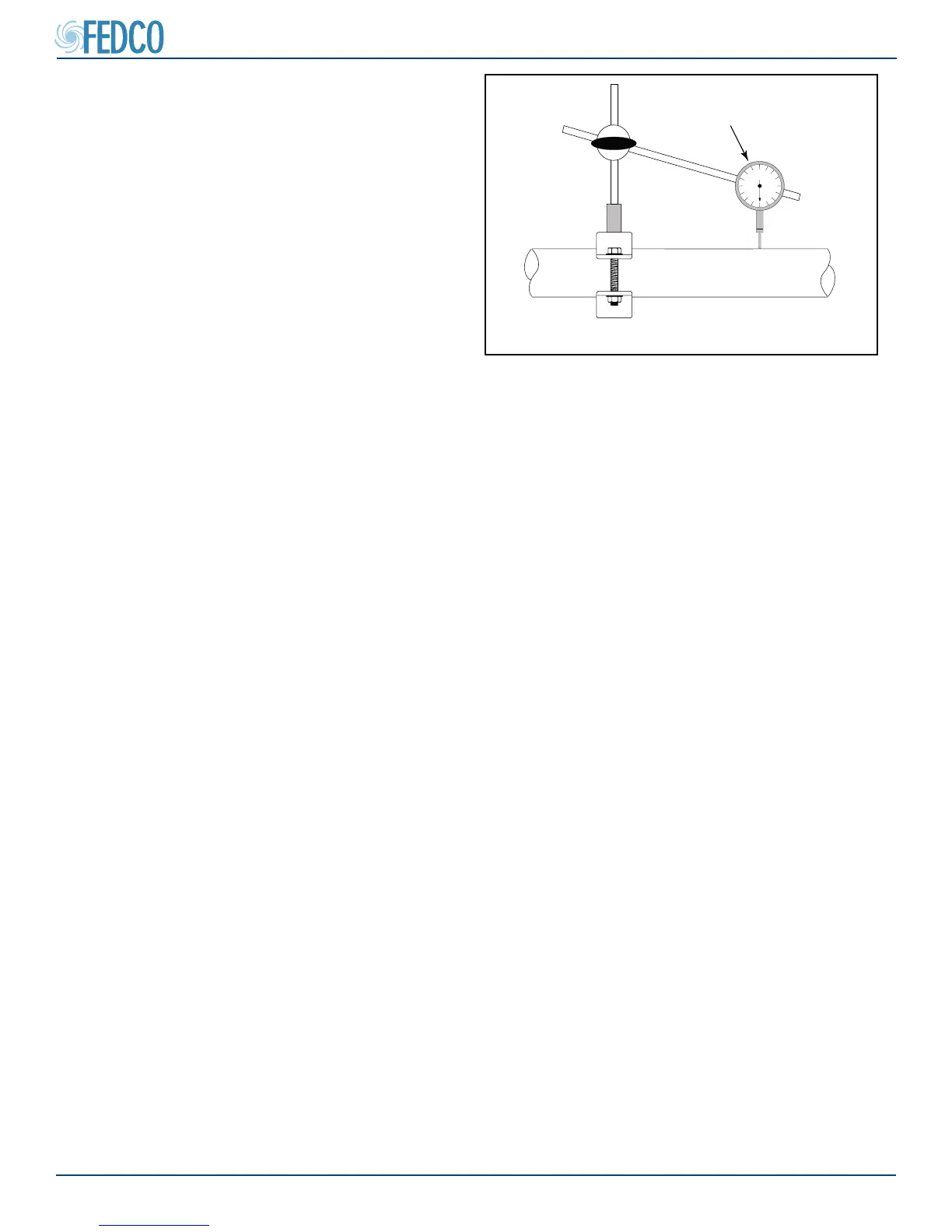

4. Without disturbing the indicator set up, return

it to its original upright position. The indica-

tor should return to zero. This veries that

no instrument drift has taken place. If instru-

ment drift has occurred, repeat the Sag Test

steps 1 through 4.

EXAMPLE: If the dial indicator registers a

reading of -0.002, Multiply the negative read-

ing by negative one half or -0.5. This will give

you a product of +0.001. Pre-setting the dial

indicator to +0.001 will compensate for the “sag

error’ during measurement procedures.

Figure 88 - Formula For Instrument Sag

Compensation

METALIC STOCK

DIAL INDICATOR RETURNS

TO ZERO SETTING

(NO INSTRUMENT DRIFT)

SAG ERROR INDICATOR READING -0.002

MULTIPLIED BY -0.5

EQUALS COMPENSATION SETTING +0.001

Loading...

Loading...