• Keep the fire extinguishers in a location that you can access easily also near where the fires can occur.

- Examine the fire extinguishers regularly, refer to the manufacturer's equipment manual.

- Make sure that the fire extinguisher is full and in a condition that operates.

• For fires of material other than crop (for example oil or electrical components), use a dry chemical fire

extinguisher of A, B or C class.

• Before you cut, weld, or grind on the machine, remove flammable materials from the machine and the

work area.

• If a fire occurs, move out of the smoke and away from the fire. Get aid from your local emergency

services.

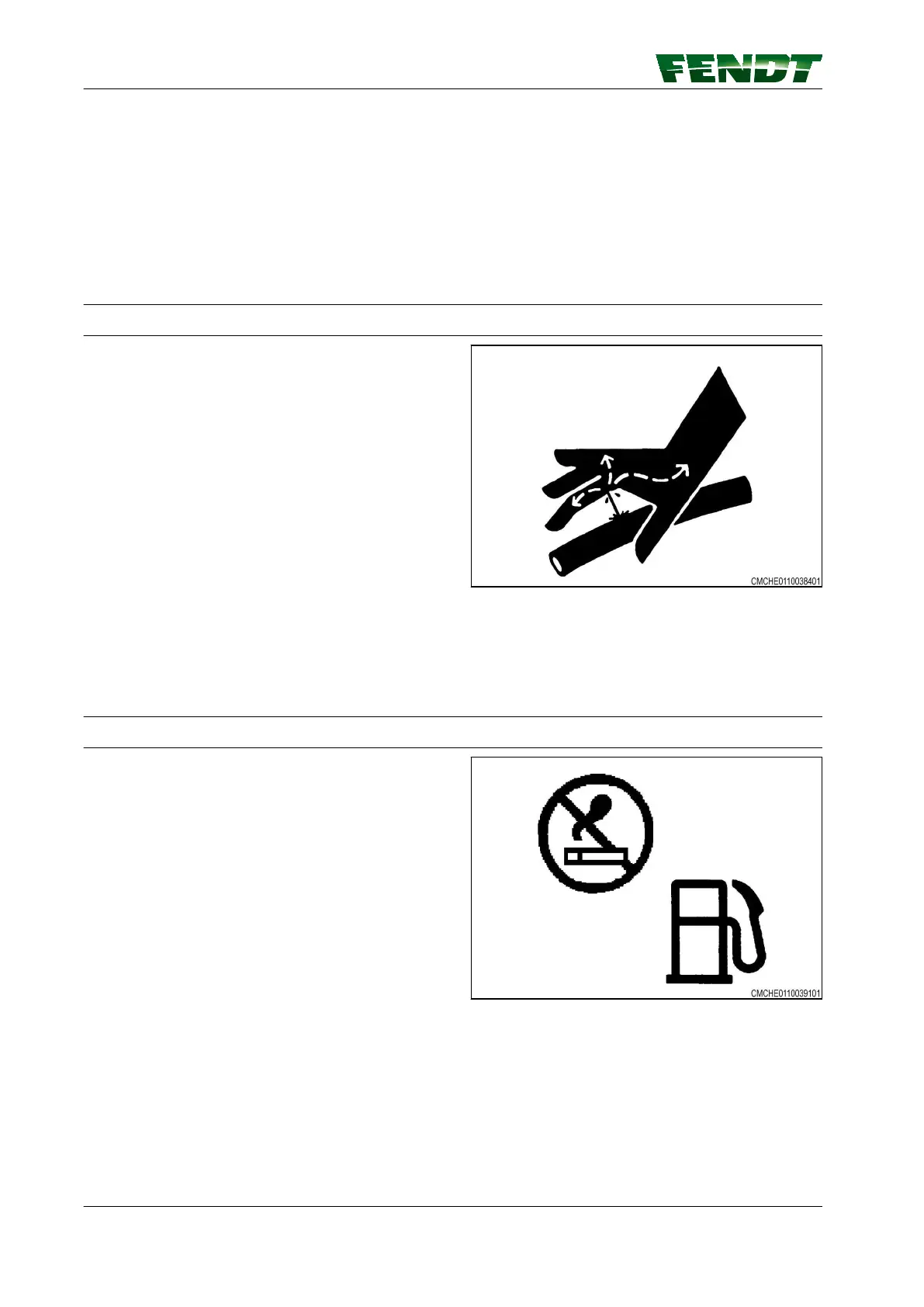

1.6.4 High pressure leaks

• The fluid that leaks from the hydraulic system

or the fuel injection system is at a high

pressure and is not easy to see.

• If the fluid goes into the skin, you must get

medical aid immediately. If the fluid is not

removed immediately, injury or death can occur.

• Use the applicable procedures to find possible

leaks.

- Do not use your bare hand.

- Put on the correct personal protective

equipment before you look for leaks.

• Before you replace hydraulic lines:

- Remove all pressure from the system.

- Put all equipment in the maintenance

position and install the supports if it is

applicable.

- Close the applicable accumulator valves.

- Stop the engine.

GUID-CB450E2E-50DF-4D16-9E59-21C0B3E5B026-high.jpg [High]

Fig. 17

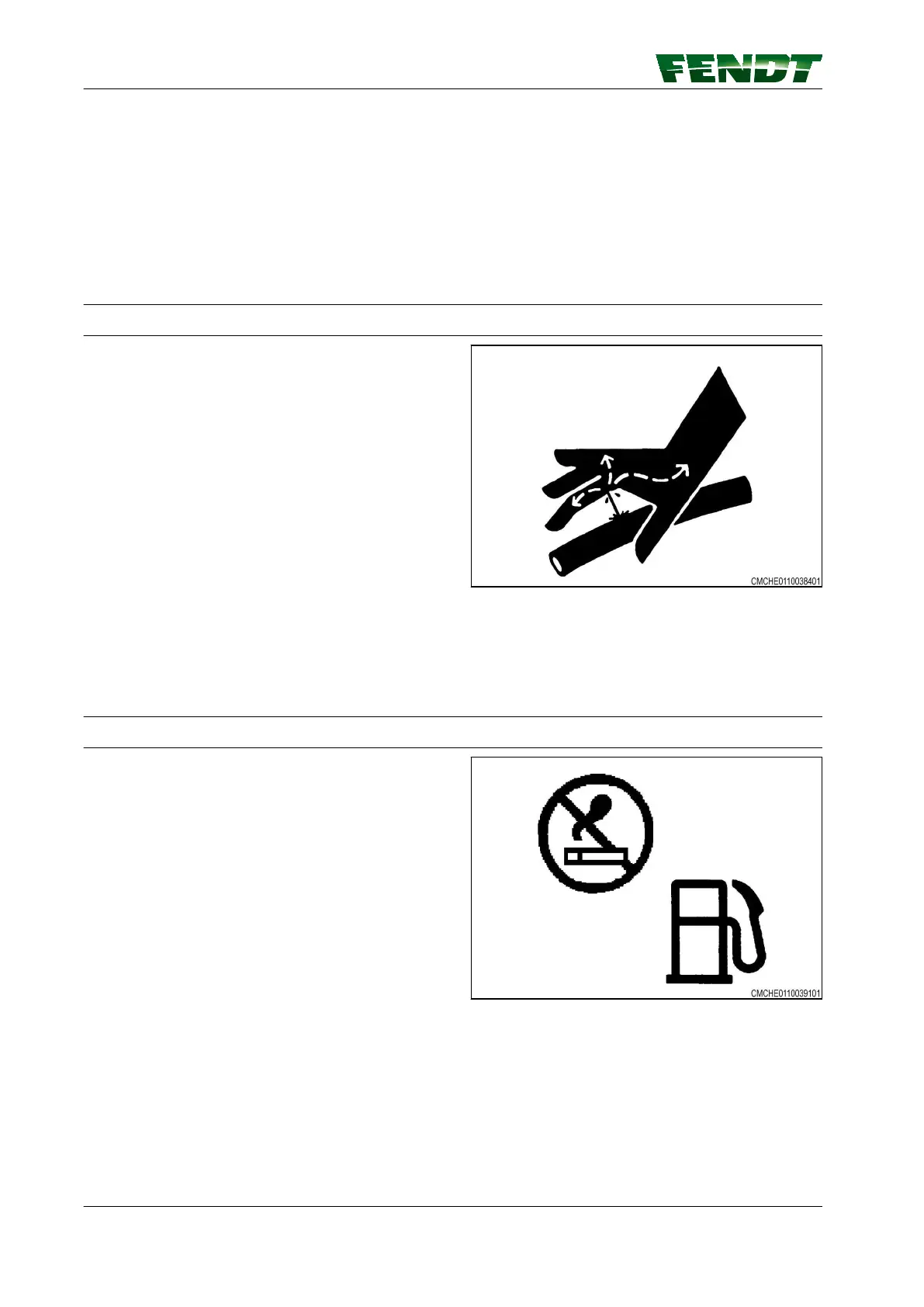

1.6.5 Fuel Safety

• Fuel is flammable.

• Always stop the engine before you put fuel in

the machine.

• Keep open flames and electrical sparks away

from the area.

• Do not smoke while you add the fuel.

• Clean the area and remove spilled fuel.

• Only use fuel from an approved fuel container.

• Make sure that a class B fire extinguisher is

available when you fill the machine with fuel.

GUID-C7F758F4-CC0C-482B-9ED5-26557B3F0262-high.jpg [High]

Fig. 18

GUID-79804E84-5AE4-43FC-871E-0632EEF914F7 [V1]

GUID-C83E73C4-4979-4F45-AEE0-E3635D592CB7 [V1]

1. Safety

34 IDEAL Series Combine

ACX2738370

Loading...

Loading...