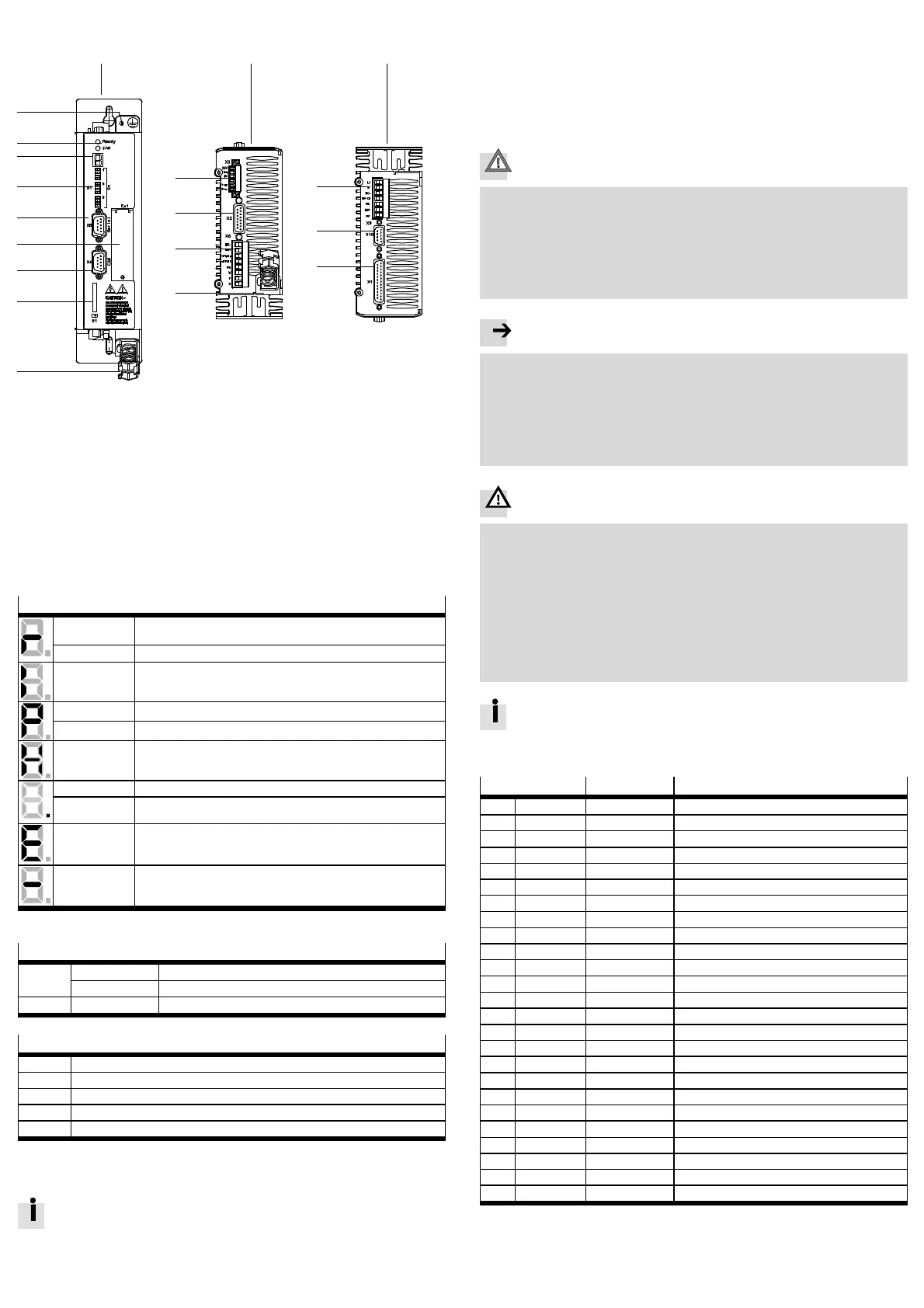

2 Product overview

2.1 Device view

123

4

5

6

7

8

9

aJ

aA

aB

aC

aD

aE

aF

aG

aH

aE

1 Front view

2 Bottom view

3 Top view

4 Earthing screw (central PE

connection)

5 LED status display

6 7-segments display

7 [S1]: DIP switch

8 [X5]: RS232/RS 485

9 [EXT]: Slot for CAMC-...

aJ [X4]: CAN bus

aA [ M1]: S D memory card

aB [ X3] STO interface

aC [ X2] Encoder

aD [ X6] Motor

aE Shield connection terminal

aF [X9] Power supply

aG [ X10] Master/Slave

aH [ X1] I/O interface

Fig. 1 Motor controller CMMS-AS-...-G2

2.2 Display and c ontrol elements

7-segments display

1)

Rotating outside

segments

Speed mode (speed adjustment):

Display changes corresponding to rotor position and speed.

Middle segment Controller enable active (motor is energised).

I Force mode (current control).

Pxxx Positioning mode, record number x x x

PHx Homing phase x

H Two-channel safety function requested (DIN4 [X1.21] and Rel [X3.2]).

Point Start program (Bootloader) active.

Flashing point – Firmware file (memory card) is being read.

– Display of errors through the start program.

Exxy Error (E = error)

Number: Two-position main index (x x), single-position subindex (y)

Example: E 0 1 0 section 7.

–xxy– Warning

Number: Two-position main index (x x), single-position subindex (y).

Example:-170- section 7.

1) Several characters are displayed one after the other.

LED display

Ready Green Operating status/controller enable

Flashing green Parameter file (memory card) is being red/written

CAN Yellow Status display: CAN bus active

DIP switch

S1.1 … 7 CAN bus address or MAC-ID

S1.8 Automatic loading of new firmware and parameter files from memory card

S1.9 … 10 Setting th e CAN-bus transmission rate

S1.11 Activatio n of th e CAN-bus interface

S1.12 Terminating resistor for CAN-bus

3 Mechanical installation

3.1 Assembly

Observe the information on the installation dimensions and free spaces in

the hardware description GDCP-CMMS-AS-G2-HW-...

For vertical mounting onto a control c abinet mounting plate:

• Mount the ac c ompanying mounting bracket to the motor controller.

• Use the motor controller exclusively in a control cabinet:

– The mounting position is vertical with the power supply lines [X9] lea ding

upwards.

– Mounting to the mounting brackets with M5 screws.

4 Electrical installation

Caution

Danger from u nexpected movement

Faulty pre-assembled lines may destroy the electronics and trigger unexpected

movements of the motor.

• When wiring the system, use only the supplied plug connectors and prefe r ably

the cables listed in the catalogue as accessories.

www.festo.com/catalogue

• Lay all flexible lines so that they are free of kinks and free of mechanical

stress; if necessary use chain link trunking.

Note

ESD (electrostatic discharge) c an cause damage to the device or other system

parts at plug connectors that are not used.

• Before installation: Earth the system par ts and use appropriate ESD equip-

ment ( e.g. shoes, earthing straps etc.).

• After installation: Seal unassigned D-sub plug connectors with protective caps

(available at authorized dealers).

• Observe the handling specifications for electrostatically sensitive devices.

Warning

Danger of electric shock

Motor controllers are devices with increased leakage current ( > 10 mA). If wiring

is incorrect or the device is defective, high voltage can occur on the housing,

which can result in serious injury or even death if the ho using is touc hed.

• Before commissioning, also for brief measuring and test purposes, connect

the PE protective c onductor:

– to the earthing screw of the c ontroller housing,

– to pin PE [X9.5], power supply. The cross section of the protective conduct-

or at PE [ X9.5] must correspond at least to the cross section of the external

conductor L [ X9.1].

• Observe the regulations of EN 50178 and I EC 60204-1.

Observe th e information on safe and EMC-suitable installation and on

protective earthing in the Hardware desc riptio n GDCP-CMMS-AS-G2-HW-...

4.1 I/O interface [X1]

Pin

Value Assignment in 0 mode – positioning

1 SGND 0V Screening for analogue signals

2 DIN12/AIN0 – Mode bit 0/setpoint input 0

2)

3 DIN 10 – Record selection bit 4 (high active)

4 +VREF +10V ±4 % Reference output for setpoint value potentiometer

5 – – –

6 GND24 – Reference potential for digital I/O modules

7 DIN 1 – Record selection bit 1 (h igh active)

8 DIN 3 – Record selection bit 3 (h igh active)

9 DIN 5 – Controller enable (high active)

10 DIN 7 – Limit switch 1

11 DIN 9 – Mode bit 1

12 DOUT1 24 V 100 mA Motion complete (high active)

1)

13 DOUT3 24 V 100 mA Common error (low active)

1)

14 AGND 0V Reference potential for analogue signals

15 DIN13/#AIN0 –/Ri = 20 kΩ Stop (low active)/reference potential AIN0

2)

16 DIN 11 – Record selection bit 5 (high active)

2)

17 AMON0 0…10V±4% Output: a nalogue monitor 0

18 +24VDC 24 V 100 mA Output: 24 V DC, lo oped through from [X9.6]

19 DIN 0 – Record selection bit 0 (high active)

20 DIN 2 – Record selection bit 2 (high active)

21 DIN 4 – Output stage enable (h igh active)

22 DIN 6 – Limit switch 0

23 DIN 8 – Start for the positioning procedure (high active)

24 DOUT0 24 V 100 mA Output: Controller ready for operation (high active)

25 DOUT2 24 V 100 mA Start acknowledged (low active)

1)

1) Default setting, configurable in the Festo Configuration Tool (FCT).

2) Pin allocation with control via analogue input

Loading...

Loading...