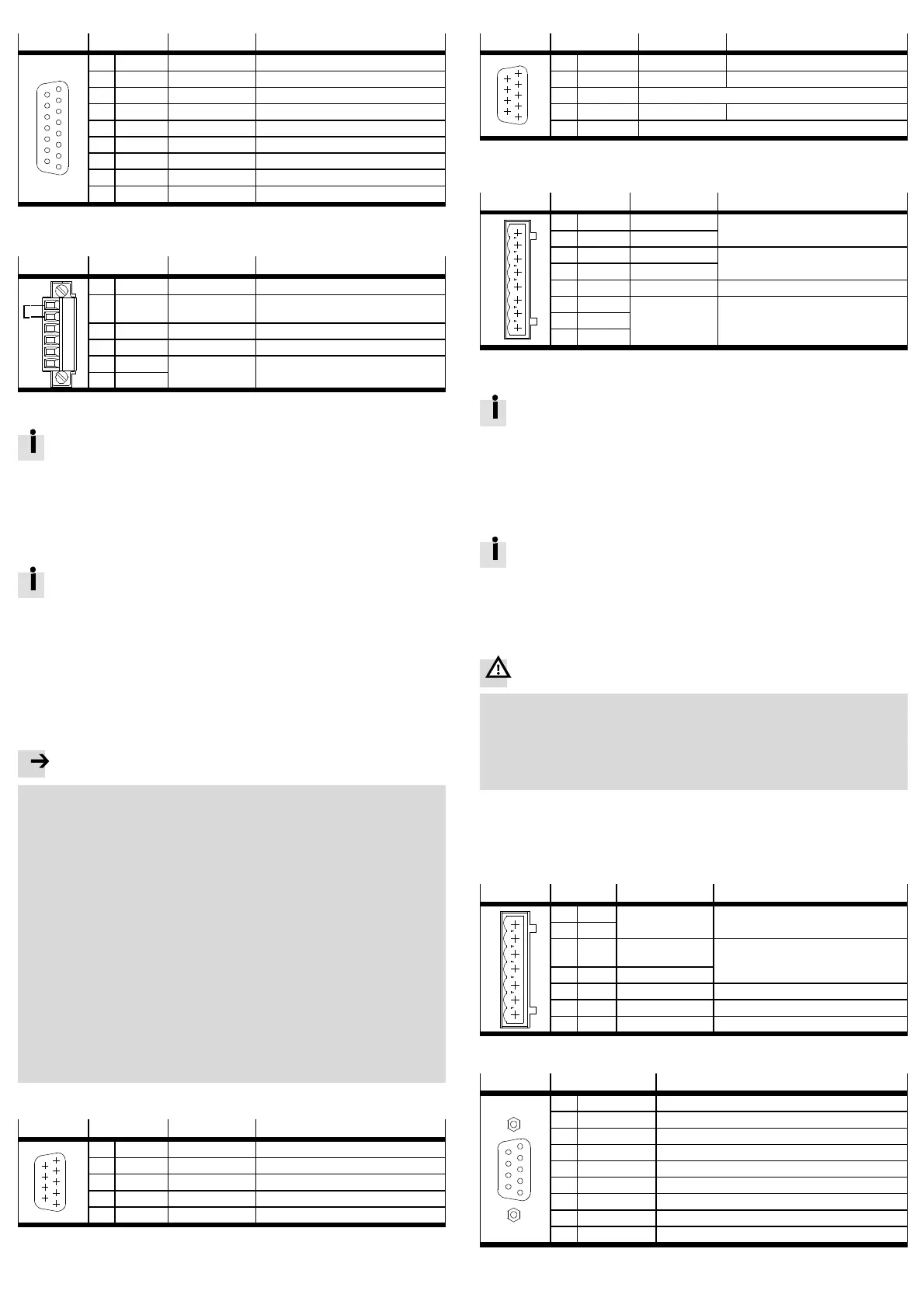

4.2 Encoder [X2]

[X2]

Pin Value Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1 M

T+

+3.3 V / 3 mA Temperature sensor, motor temperature.

2 –U_SENS 0V Connected internally with pin 3

3 GND 0V Reference potential US and M

T+

5 #DATA U

SS

=5V RS485 data transmission line (differential)

6 #SCLK U

SS

=5V Cycle o utput RS485 EnDat interface

9 +U_SENS 5V(–0%…+5%) Connected internally with pin 10

10 US 5V(–0%…+5%) Operating v o ltage for EnDat encoder

12 DATA U

SS

=5V RS485 data transmission line (differential)

13 SCLK U

SS

=5V Cycle o utput RS485 EnDat interface

4.3 STO interface [X3]

Interface [X3] ( Circuitry without use of the STO safety function)

[X3]

Pin Value Description

1

2

3

4

5

6

1 24 V 24 V DC 24 V DC supply carried out

2 REL 0V/24VDC Setting and resetting th e relay for

interrupting the driver supply

3 0V 0V(GND24VDC) Reference po tential for PLC (24 V DC)

4 – – –

5 NC1 Max. 25 V AC,

30 V DC, 2 A

Potential-free feedback contact for driver

supply, NC contact

6 NC2

Circuitry without use of the STO safety function

If you do not need the integrated safety function STO in your application,

to operate the motor controller you must bridge Pin 1 and Pin 2 at the X3

interface.

This deactivates the integrated safety function!

With this circuitry, safety in the application must be ensured through other

appropriate measures.

Use of the STO safety function

For intended use of the safety function STO – “Saf e Torque Off ”, observe

the information in the STO description GDCP-CMMS-AS-G2-S1-...

Use the “Safe Torque Off ” function (STO) whenever you have to reliably disconnect

the energy supply to the motor in your part icular application. To ensure the func-

tion STO “Safe Torque Off ”, the c ontrol ports DIN4 [ X1.21] and Rel [X3.2] must be

connected in two channels through parallel wiring. This interface can be part of an

emergency stop c ircuit or a protective door arrangement, for example.

Recommendation for initial start-up without safety equipment:

Minimum circuitry with emergency stop switching device and two-channel switch-

off via the control ports REL [X3.2] and DI N4 [ X1.21] .

Note

Loss of the safety function.

Lack of the safety function can result in serious, irreversible injuries, e.g. due to

uncontrolled movements of the connected actuator technology.

– The STO function request must always run over X3.2 and X1.21 (end stage

enable).

– If uncontrolled coasting can result in a hazard or damage, additional meas-

ures a re required.

– A clamping unit is actuated by the non-safety-relevant firmware of the CMMS-

AS -...-G2 motor controller.

• Make sure that no jumpers or the like can be inserted parallel to the safety

wiring, e.g. through the use of the maximum wire c ross section of 1.5 mm² or

suitable wire end sleeves with insulating collars.

• Use twin wire end sleeves for looping through lines between neighbouring

devices.

• Comply with the specified environmental and connection conditions, in partic-

ular the input voltage tolerances.

• Place the motor controller in operation only if all safeguarding, including the

safety function, has been installed and checked.

• The safe ty function must be checked and, prior to the intended use, a corres-

ponding v alidation must be carried out.

4.4 CAN [X4]

[X4]

Pin Value Description

5

1

2

3

4

6

7

8

9

2 CANL 5V,Ri=60Ω CAN low, signal line

3 GND – CAN GN D, not galvanically isolated

5 Screening – Connection for the cable screening

6 GND – CAN GN D, not galvanically isolated

7 CANH 5V,Ri=60Ω CAN high signal line

4.5 Serial interface RS232/RS485 [X5]

[X5] RS232

Pin

1)

Value Description

5

1

2

3

4

6

7

8

9

2 RS232_RxD 10 V, Ri > 2kΩ Receive signal

3 RS232_TxD 10 V, Ra < 2kΩ Transmission signal

4 RS485_A Positive transmission and receive signal

5 GND 0V Reference potential 0 V DC

9 RS485_B Negative transmission and receive signal

1) Connect only the pins for RS232 or RS485, dependent on the interface used!

4.6 Motor [X6]

[X6]

Pin

1)

Value Description

1

2

3

4

5

6

7

8

1 BR– 0V For motors E MMS-AS-…- TSB/TMB:

holding brake (motor)

2 BR+ 24 V

3 M

T–

0V Temperature sensor (N/C contact, N/O

contact, PTC or KTY)

4 M

T+

+3.3V,5mA

5 PE – PE connection of the motor cable

6 W Hardware

description

Connection of the three motor phases

7 V

8 U

1) In the motor and connecting cable, reliable separation of the motor temperature sensore from the motor

circuit must be ensured.

If third-party cables are used: Place the complete screening of the motor-

side c able f lat on the plug or motor housing. Length ≤ 40 mm.

• Place the c omplete screening of the motor c able at the screening con-

nection terminal of the related motor controller so that the leaked cur-

rent can flow back into the controller causing it

• Do not use the complete screening as strain relief.

Connection of a holding brake

Holding brakes are not appropriate for braking the motor. They only serve

functional holding of the motor shaft. Additional measures are required for

use in safety-oriented applications.

4.7 Power supply [X9 ]

Protection against electric shock through protective extra-low voltage (PELV):

Warning

Danger of electric shock

• Only use PELV circuits in accordance with IEC/E N 60204-1 (protective

extra-lo w voltage, PELV) for the electrical power supply.

Also observe the general requirements for PELV circuits as per

IEC/EN 60204-1.

• Only use voltage sources which guarantee reliable electrical isolation of the

operating voltage in ac c ordance with I EC/EN 60204-1.

The use of PE LV circuits ensures protection from electric shock (protection from

direct and indirect contact) in accordance with IEC/EN 60204-1 (Electrical equip-

ment of machines, General requirements). A 24 V power supply unit used in th e

system must satisfy the requirements of EN 60204-1 for DC power supply (beha-

viour during power interruptions, etc.).

[X9]

Pin Value Description

1

2

3

4

5

6

7

1 L1 1-phase

95 ... 250 V AC

Mains voltage connection for intermediate

circuit voltage

2 N

3 IC + 320 V DC

(max 400 V DC)

Connection for external braking resistor

Hardware description

Not short-circuit proof against L1, N, PE

4 BR-CH 0 V/400 V, max. 4 A

5 PE PE Mains-side PE connection

6 24 V +24 V/1.7 A Supply of the control section, DOUT..., etc.

7 0V GND Common reference potential L1/24 V

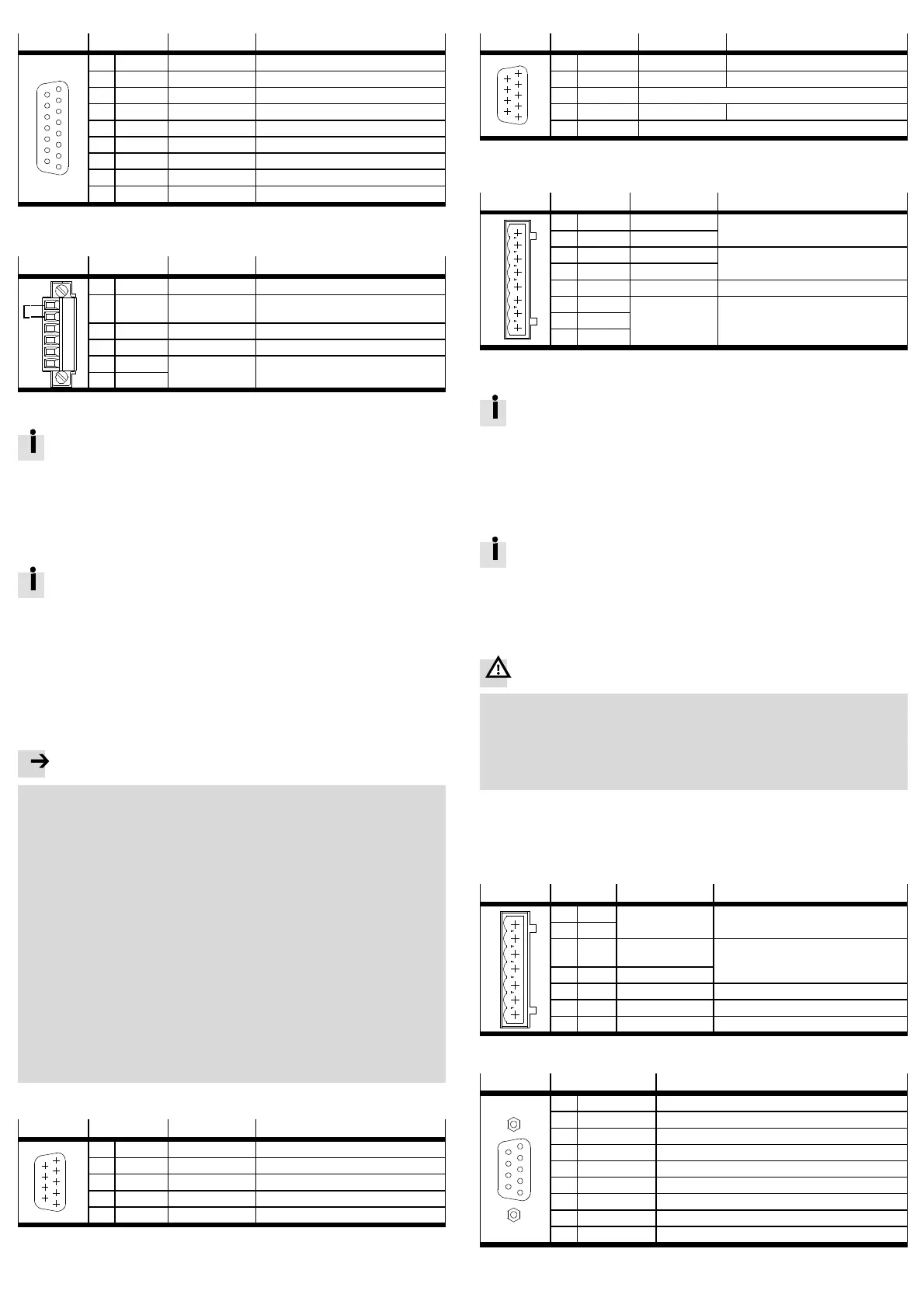

4.8 Master/ slave interface [X10]

[X10]

Pin Description

6

7

8

9

2

1

3

4

5

1 A/CLK/CW Tracking signal A/pulse CLK/steps CW

2 B/DIR/CCW Tracking signal B/direction DIR/steps CCW

3 N Incremental encoder zero pulse N

4 GND

1)

Reference GND for incremental encoder

5 VCC Auxiliary supply, maximum load 100 mA

6 #A/#CLK/#CW Tracking signal A/pulse CLK/steps clockwise CW

7 #B/#DIR/#CCW Tracking signal B/direction DI R/steps CCW

8 #N Zero pulse N

9 GND

1)

Screening for the connecting cable

1) Pin 4 and pin 9 are connected internally

Loading...

Loading...