• Note the warnings and instructions on the product and in the relevant operating

instructions.

• Ensure t hat there is a supply of correctly prepared compressed air ( Technical

data).

• Pressurise your entire system slowly. There will t hen be no uncontrolled move-

ments.

5 Installation

5.1 Mechanical

Note

• Installation and c ommissioning may only be performed in acc ordance with the

operat ing instructions and by qualified personnel.

• Handle the VPPM-...C1 with care so that the electrical c onnection is not dam-

aged. This could lead to an impairment of function.

• Make sure there is sufficient space for the cable

connection and tube couplings. In this way you will

prevent the c onnecting cable from being bent.

• Place the VPPM-...C1 as near as possible to the

consuming device. This leads to improved control

precision and shorter response times.

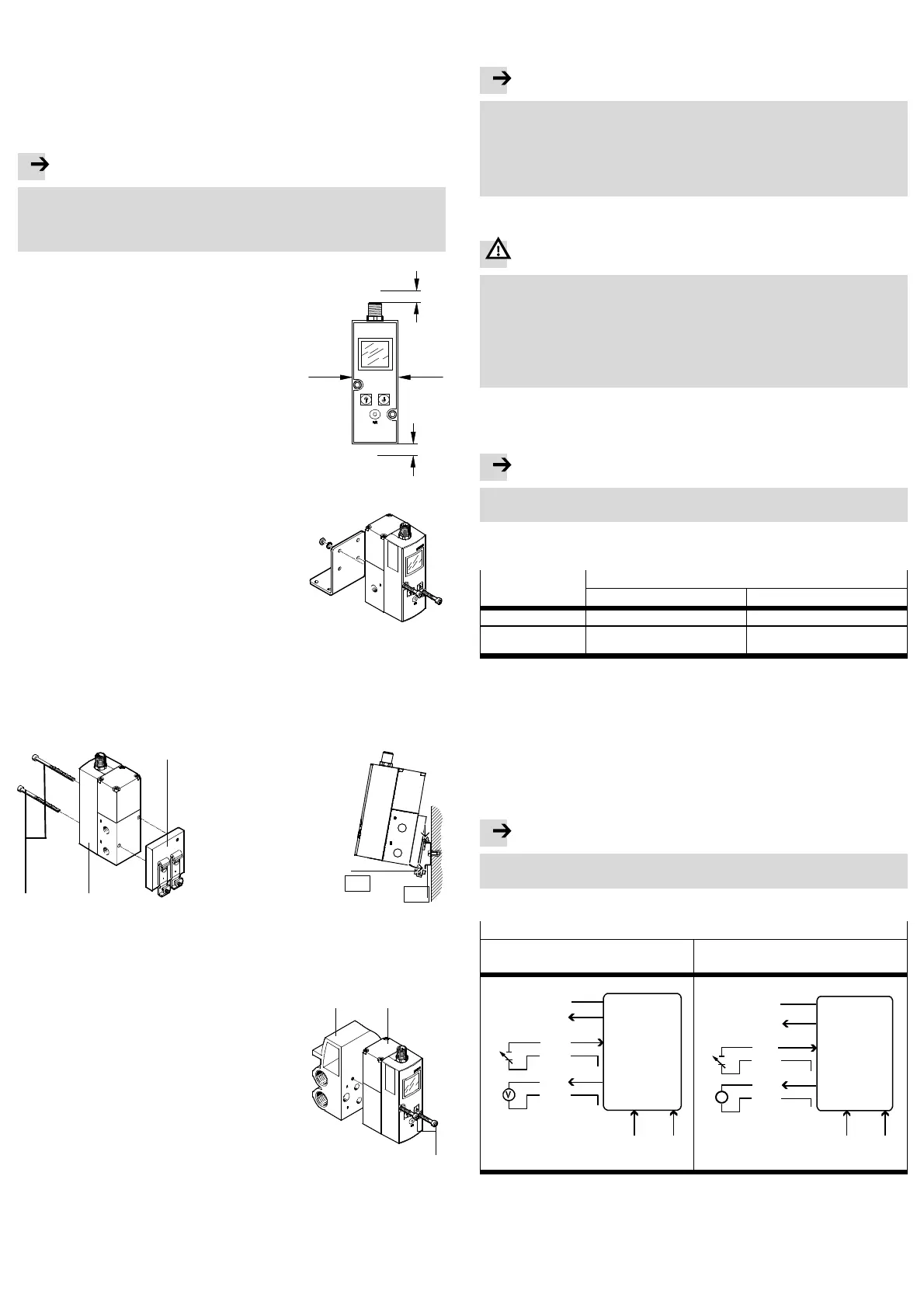

Fig. 6

Wall mounting (in-line valve)

• Fasten the VPPM-...C1 (1/8” and 1/4”) in the inten-

ded position with two M4 screws. In order to do

this use bracket type VAME-P1-A (see diagram).

When mounting the VPPM with the aid of the brack-

et, the VPPM-...C1 may only be loaded statically

(torque: approx. 1.5Nm).

• Fasten the VPPM-…C1 (1/2”) with two M5 screws in

the intended position (torque 2.0Nm).

Fig. 7

H-rail mounting (in-line valve)

• Mount the H-rail adaptor on the VPPM-...C1 using the screws included (x”: M4

x 65, ¼”: M4 x 77) (torque approx. 1.5Nm).

• Hang the VPPM-... onto the H-rail.

• Secure the VPPM...C1 with the retaining screws of the H-rail adapter ( torque

1.5Nm).

1

2

3

4

5

1 H-rail adapter

type VAME-P1-T

2 VPPM-...C1

3 Mounting screws M4

4 H-rail

5 H-rail clamping unit

Fig. 8

Sub-base mounting (flanged valve)

• Fasten the VPPM-...C1 2 on the pneumatic mani-

fold rail type VABM-P1-SF-G18-...1.

• Tighten the fastening screws 3 (torque 1.5 Nm).

Fig. 9

1

2

3

5.2 Pneumatic (in-line valve)

• Remove the sealing elements from the compressed air ports.

• Attach the pneumatic tubing to the following connections ( Fig. 1):

– Supply port (1) Item. 5

– Supply port (2) Item. 2

• Install a silencer at the exhaust por t (3) item 3 or remove the exhaust with

ducted tubing.

Operating medium

Note

Too much residual oil content in th e compressed air will reduc e the service life of

the valve.

• When using bio-oils (oils that are based on synthetic ester or native ester, e.g.

rapeseed oil methyl ester), the maximum residual oil content of 0.1 mg/m³

should not be exceeded

( ISO 8573-1:2010 [7:4:2]).

5.3 Electric

Warning

For electrical isolation of operating voltage:

• Only use PELV circuits as per IEC/EN 60204-1 (protective extra-low voltage,

PELV) for the electrical power supply.

Also observe the general requirements for PELV circuits in accordance with

IEC/EN 60204-1.

• Use only power sources which guarantee reliable electrical isolation of the

operating voltage as per IEC/EN 60204-1.

Protection against electric shock (protection against direct and indirect contact) is

guaranteed in accordance with IEC/EN 60204-1 by using PE LV c ircuits (electrical

equipment of machines, general requirements).

Note

Long signal lines reduce the resistance to interference.

• Make sure that the signal cables are not longer than 10 m.

•

Check by means of the type plate to ascertain which valve variant you

have:

Designationontheratingplate

VPPM-...-V1...C1 VPPM-...-A4...C1

Designation Voltage variant Current variant

Electrical setpoint

value

DC 0 ... 10 V 4 ... 20 mA

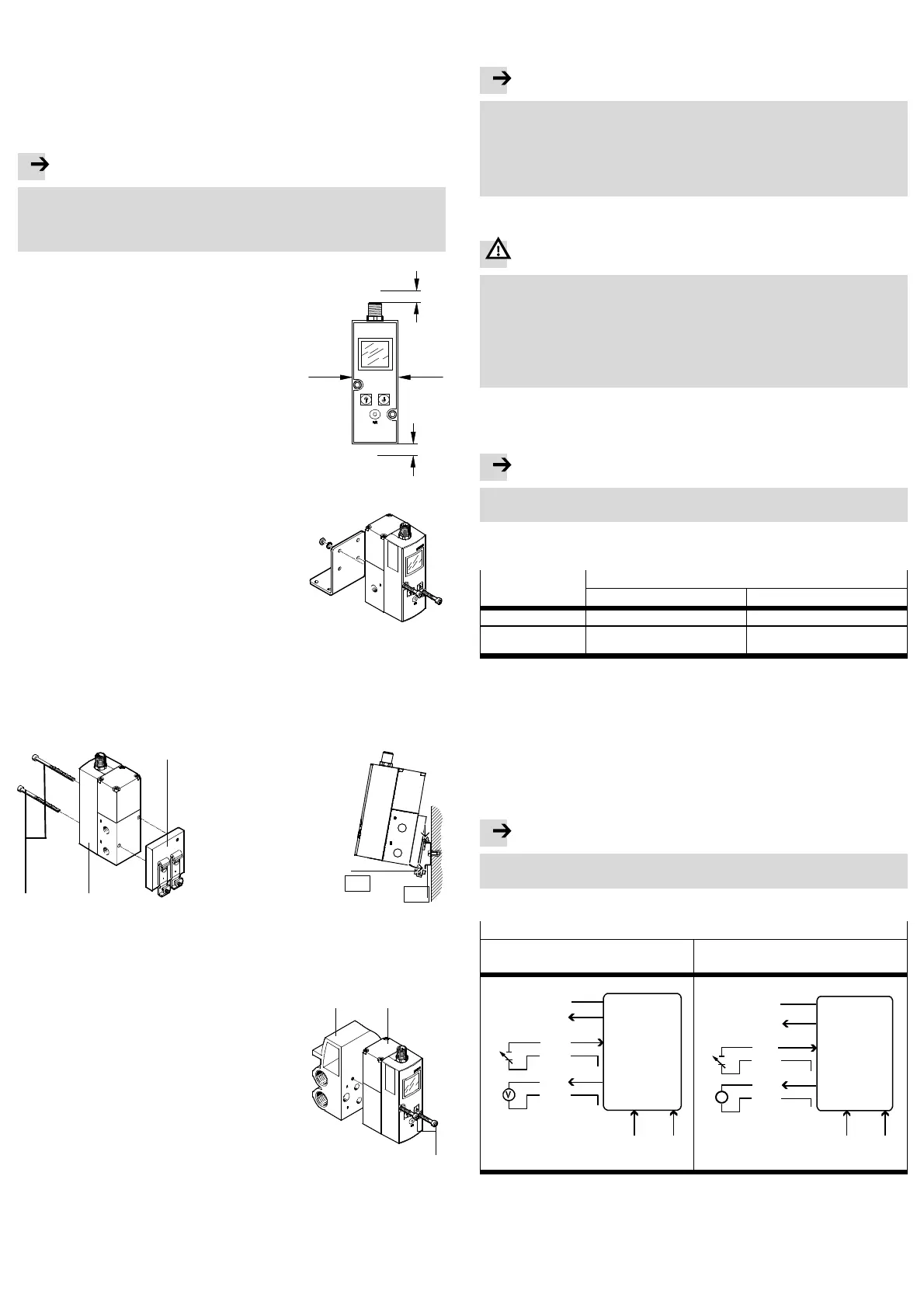

Fig. 10

• Check whether the following options are required on the VPPM-...C1:

– measuring the actual voltage/current value

• Make sure that the cables are not squashed, bent or stretched.

• Use the pre-assembled cable with socket from Fe sto (Accessories

www.festo.com/catalogue). You can then guarantee that the specified protec-

tion class IP 65 and EMC are fulfilled.

• If a screened cable is used, earth t he screening on the opposite end of the cable

from the VPPM-...C1.

Note

If the Y-connecting cable type NEBV-M12G8-KD-..-M12G5 is connected to CPX

I/O modules, the I/O modules will no longer be galvanically isolated.

• Connect the cables of the VPPM-...C1 in accordance with the circuit diagram.

Circuit diagrams for the VPPM-...C1

Voltage variants

(type VPPM-...-V1...C1)

Current variant

(type VPPM-...-A4...C1)

W-

8

4

3

D1

ext in

D2

ext in

1

5

7

X

GND

6

W+

D3

out

U

v

0 ...10

V

2

PIN

A

7

8

4

3

D1

ext in

D2

ext in

1

5

X

GND

6

w-

D3

out

U

v

4 ...20 mA

PIN

w+

2

Fig. 11

• The individual pins on the electrical connection are assigned as follows:

Loading...

Loading...