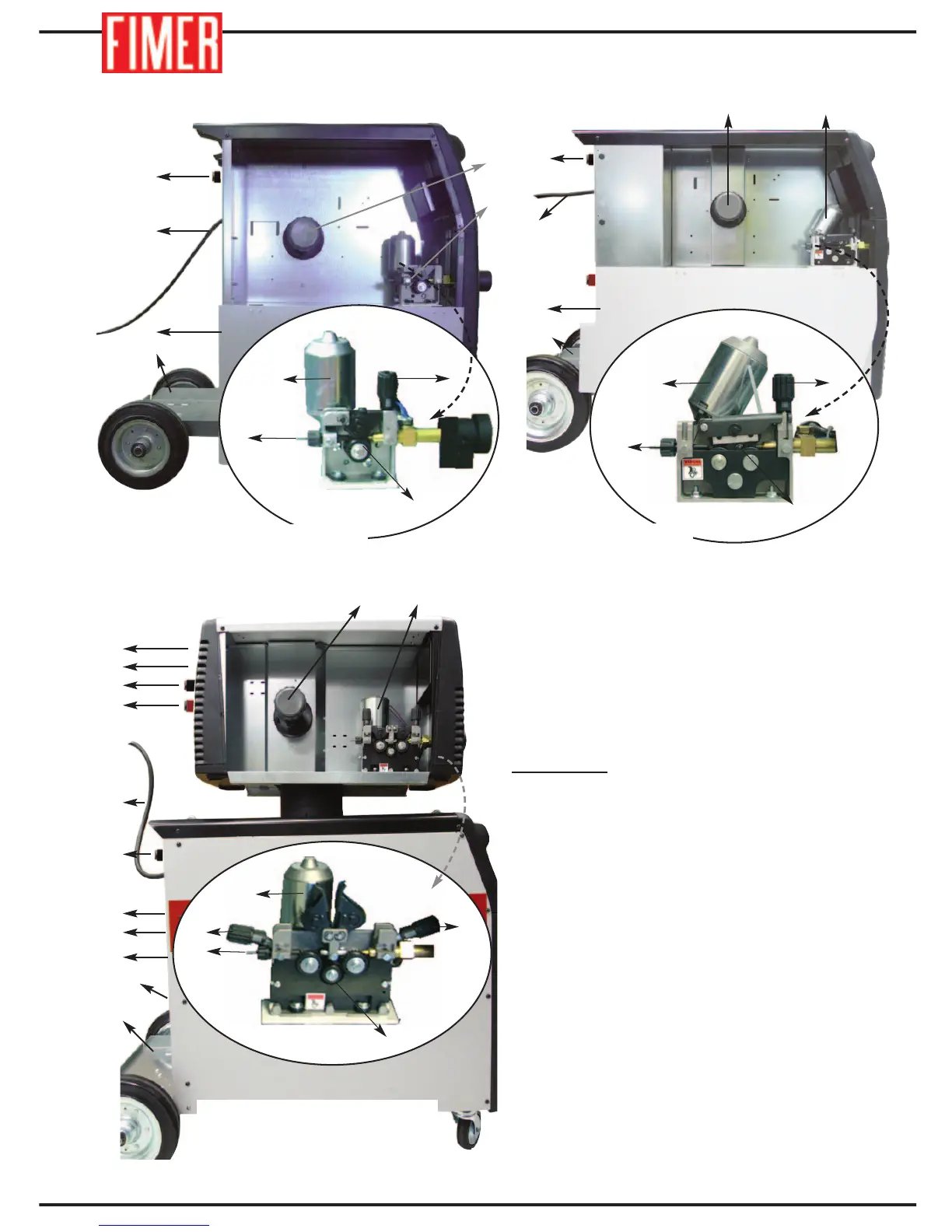

21

23

24

Fig.2A

28

27

29

26

TM 230 - TM 260

23

24

22

33, 34

25

21

F

ig.2A

28

27

29

26

TM 300- TM 350

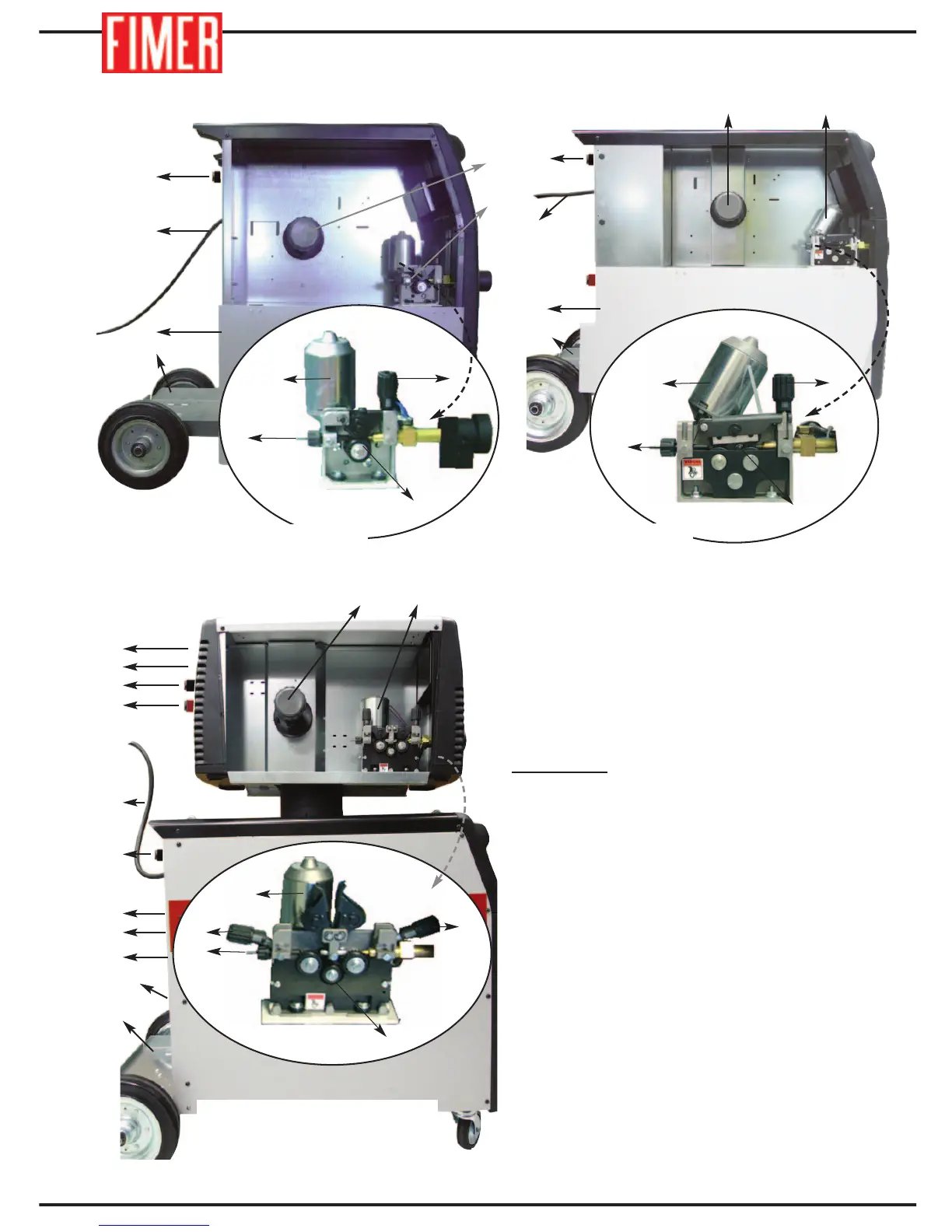

Fig.2A

28

27

27

29

26

20

TM 320W

TM 360W - TM 420W

TM 500W - TM 650W

17. H²O out: Only to be used with the “liquid

cooling” option

18. H²O in: Only to be used with the “liquid cool-

ing” option

19. TORCH QUICK CONNECTOR: Output con-

nection (positive) for the welding circuit, electrical

contacts and torch gas.

FIGURE 2

20. AIR INLET

21. GAS PIPE CONNECTOR: to be connected

to the pressure reducer of the cylinder

22. INPUT CABLE: connect this cable to the

mains power supply.

23. WIRE SPOOL

24. WIRE FEED UNIT: for more details refer to

Figure 2A.

25. SUPPORT FOR WELDING GAS CYLINDER.

26. WIRE ENTRANCE OF THE WIRE-FEED

MOTOR

27. WIRE PRESSURE REGULATOR: Allows

regulating the tension of the welding wire

28. WIRE-FEED MOTOR

29. WIRE-FEED ROLLERS

30. ELECTRICAL CONNECTOR FOR THE

SIGNALS (cable bundle) (separate trolley)

Fig. 2: SIDE VIEW

22

20

25

30

23 24

31

32

33, 34

22

21

35

36

20

37, 38

25

20

Loading...

Loading...