Type 304 & 304L

6

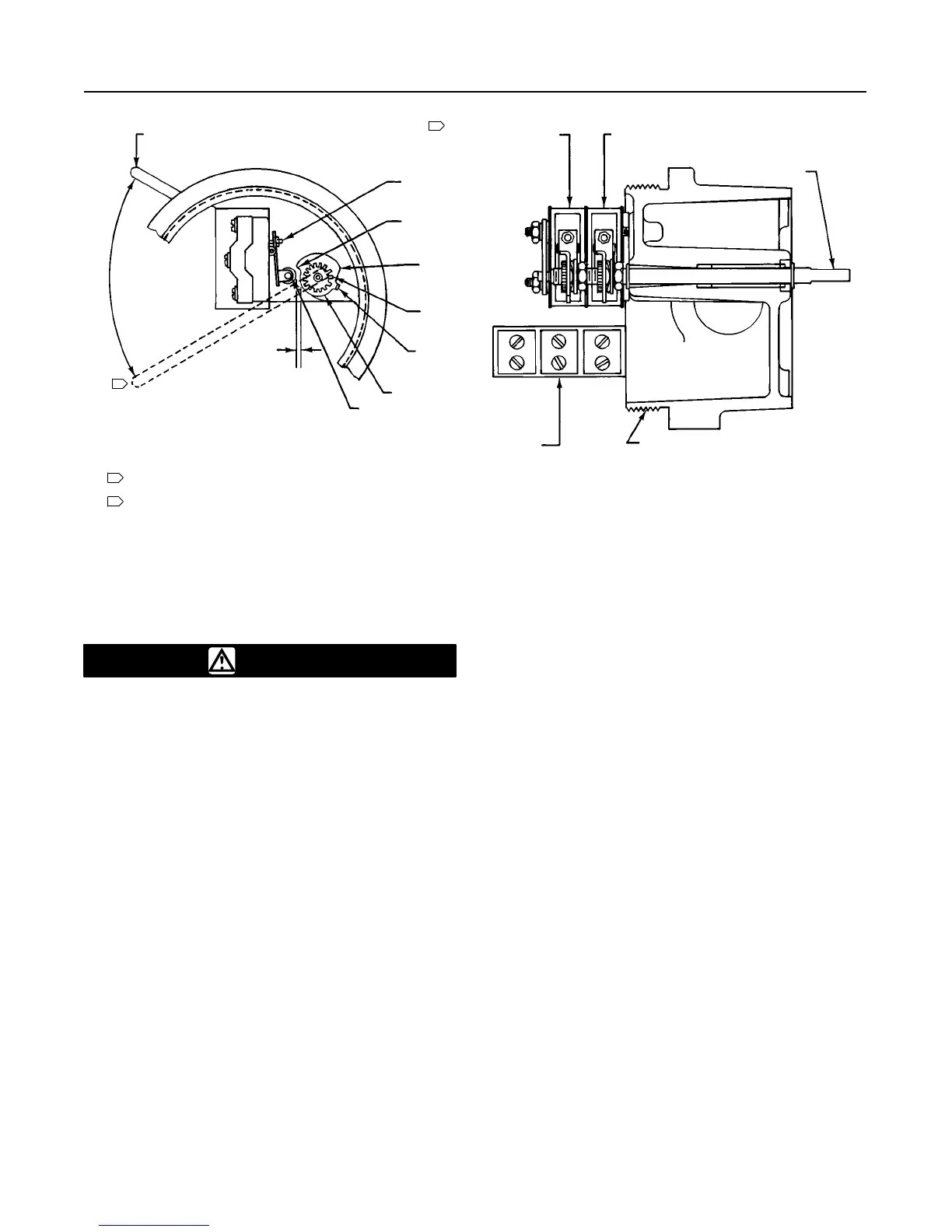

NOTES:

SWITCHES ACTUATE AS ACTUATOR STEM TRAVELS

DOWN OR AS ROTARY VALVE SHAFT ROTATES COUNTERCLOCKWISE.

SWITCH FARTHEST FROM BASE ACTUATES AT FULLY

OPEN VALVE POSITION.

Figure 5. Cam and Switch Details

42A0105–D

B1818–3 / IL

ACTUATOR STEM

UP

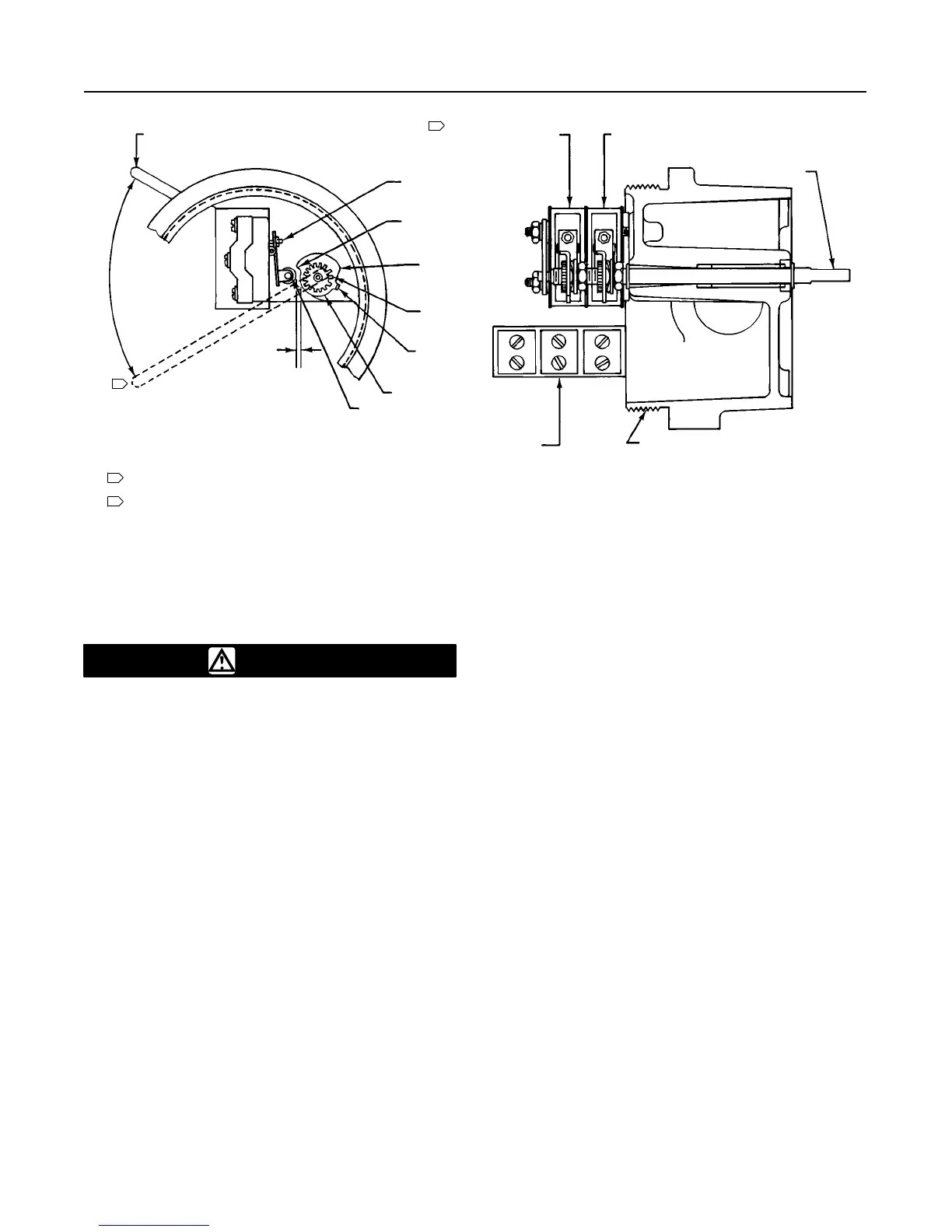

OPTIONAL SWITCHES

ARE SET AS REQUIRED

SWITCH 1 ACTUATES AT VALVE

CLOSED POSITION

CAM ROD

BASE

TERMINAL STRIPS

ARE OPTIONAL

ROLLER

ADJUSTMENT SCREW

SMALL RADIUS

CAM HEEL

GEARED NUT

CAM EAR

3/8–INCH (9.5 mm) RADIUS

ROLLER

1/16 INCH

(1.6 mm)

ACTUATOR STEM

DOWN

2

1

1

2

Adjustment

WARNING

On an explosion-proof instrument, re-

move electrical power before removing

the instrument cover in a hazardous

area. Personal injury or property dam-

age may result from fire and explosion if

power is applied to the instrument with

the cover removed in a hazardous area.

1. Position the valve or monitored device at the point

of travel where actuation of a particular switch is de-

sired.

2. Open the circuits between the switch and power

supply, and remove the switch cover.

3. Refer to figure 3. Use a light or ohmmeter to indi-

cate switch actuation. Insert a screwdriver into the

geared nut of the appropriate switch and pry against

the cam ear. Rotate the cam until its small radius (see

figure 5) contacts the lever arm roller and actuates the

switch. Tension provided by a spring washer holds the

cam in place.

4. Always adjust the cams so that the small radius of

the cam actuates the switches. This minimizes the

differential travel (dead band) required to make and

then break the circuit. The switch should not actuate

on the heel of the cam; this increases the dead band.

5. To ensure switching at the open and closed valve

positions, set the switch to actuate approximately

1/32-inch (0.8 mm) before the valve reaches these

positions.

6. The lever arm roller is preset at the factory approxi-

mately 1/16-inch (1.5 mm) from the 3/8-inch (9.5 mm)

radius of the cam, as shown in figure 5. Adjust this

dimension by turning the adjustment screw on the

switch lever arm. Use the adjustment screw only to

position the lever arm in relation to the cam; do not

use the screw to adjust the point at which the switch

actuates.

7. Replace the cover (key 2).

Principle of Operation

When used with sliding-stem valves, the operating arm

(key 49, figure 7) converts linear valve travel to rotary

motion of the cam rod.

When used with rotary shaft valves, the coupler (key

105, figure 16) links the position switch and the rotary

actuator directly and rotates the cam rod.

As the cam rod rotates, cams mounted on the rod

contact the switch rollers and actuate the switches,

which opens or closes individual switch circuits.

Loading...

Loading...