3570 Series

16

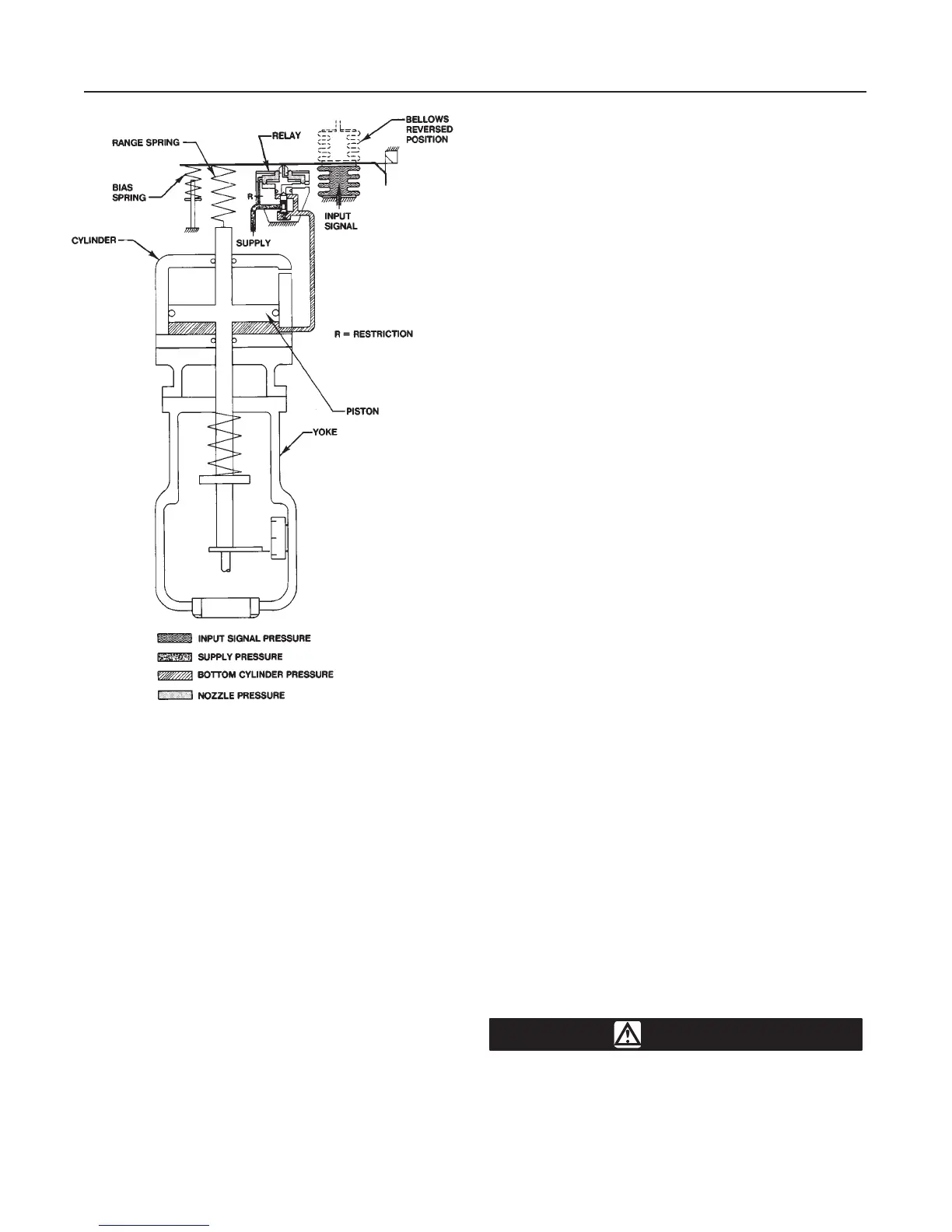

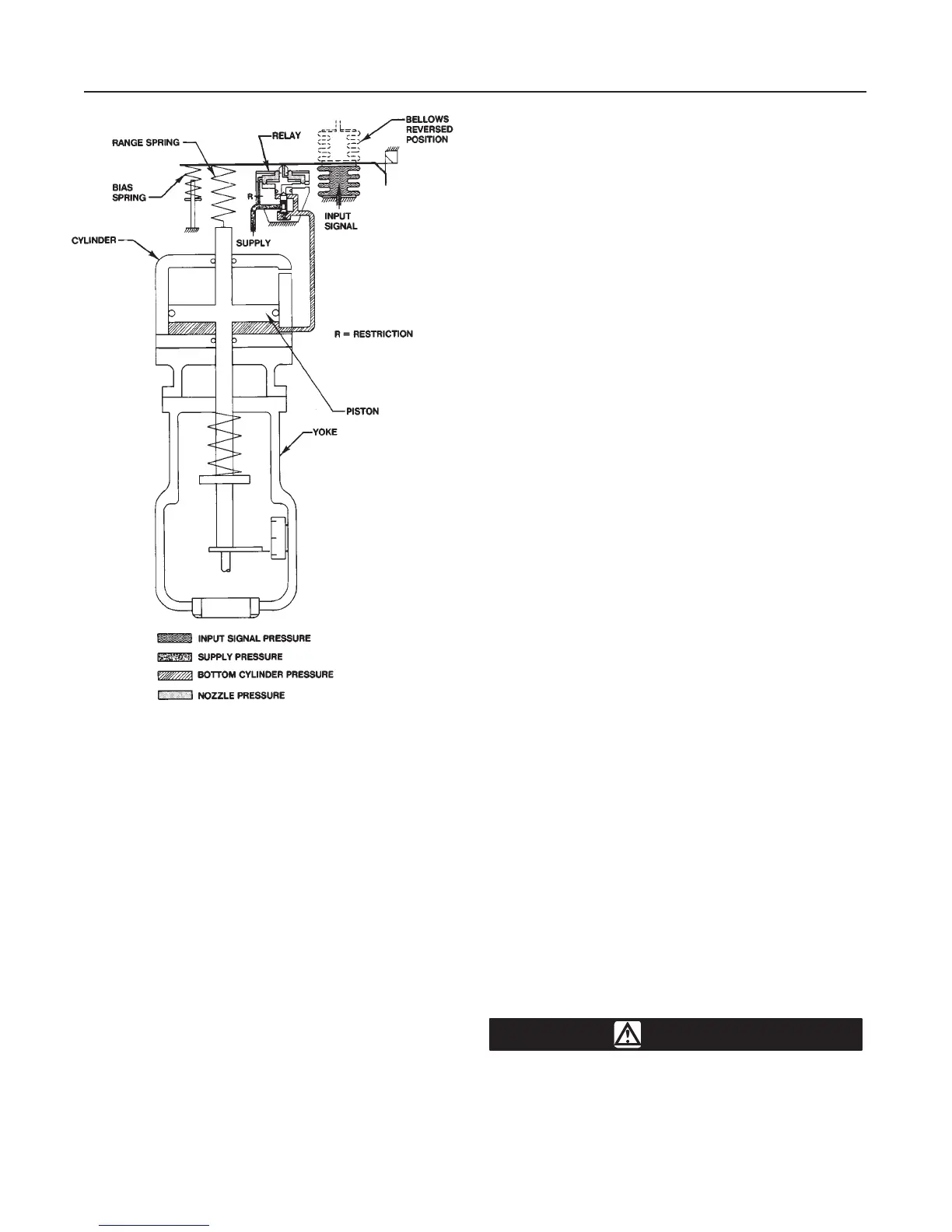

Figure 9. Schematic Diagram of T

ype 3573 Positioner with

T

ype 473 Pneumatic Piston Actuator

CR4007-A

A1082-1/IL

Relay Operation

Refer to figure 10, which shows a sectional view of a

typical relay.

Supply pressure reaches the relay(s) through pas-

sages in the positioner base and is channeled to fixed

restriction R and to point A between the supply valve

B and the balancing O-ring of the relay valve. The

fixed restriction is an integral part of the relay restric-

tion plug and wire assembly G. The orifice in nozzle F

is larger than the fixed restriction. This allows the sup-

ply pressure to bleed to atmosphere faster than it en-

ters the unit through the fixed restriction when the

beam flapper is away from the nozzle.

Assume that a change in the input signal causes the

beam flapper to cover the nozzle of a relay. The sup-

ply pressure flows through fixed restriction R into the

chamber between the two relay diaphragms. Due to

the restricting effect of the flapper over the nozzle,

pressure builds up in the chamber between the dia-

phragms, forcing the diaphragm head assembly E

downward to open supply valve B, allowing output

pressure to increase.

The supply pressure flows past supply valve B to in-

crease the output pressure to the actuator cylinder.

The cylinder pressure (relay output pressure) also acts

on the area D. This provides an air feedback that re-

turns the diaphragm head assembly E and the mov-

able nozzle F to their original positions, thus prevent-

ing any further increase in output pressure. The

feedback arrangement and the movable nozzle ensure

accurate and stable positioning of the actuator piston

without introducing cycling or over-correction. After

any change in the output pressure, supply valve B and

exhaust valve C always return to the closed position to

put the nozzle back in its original, or equilibrium, posi-

tion. The spring behind supply valve B aids in closing

the valve as the diaphragm head assembly is forced

upward.

When the beam flapper moves away from the nozzle

F, the supply pressure bleeds out at a greater rate

than it enters through the fixed restriction R. The pres-

sure then decreases in the chamber between dia-

phragms. The force of the cylinder pressure acting on

area D pushes diaphragm head assembly E upward,

opening exhaust valve C. Cylinder pressure bleeds

through the exhaust port to atmosphere. As the cylin-

der pressure decreases and the force on area D de-

creases, the force of the nozzle pressure in the cham-

ber between the diaphragms returns the assembly to

its original position. The unit is again in equilibrium, but

at a lower nozzle pressure and a lower output pres-

sure.

Each relay has a 4:1 ratio between the nozzle pres-

sure and the output pressure. For example, a 10 psig

(0.7 bar) nozzle pressure change, produces a 40 psig

(2.7 bar) output pressure change; a 20 psig (1.4 bar)

nozzle pressure change produces an 80 psig (5.5 bar)

output pressure change. With a constant input signal

pressure, the internal parts of the relay are at equilibri-

um with the supply and exhaust valves closed.

Maintenance

WARNING

Avoid personal injury from sudden re-

lease of process pressure. Before per-

forming any maintenance operations:

Loading...

Loading...