Designs D & DA

2

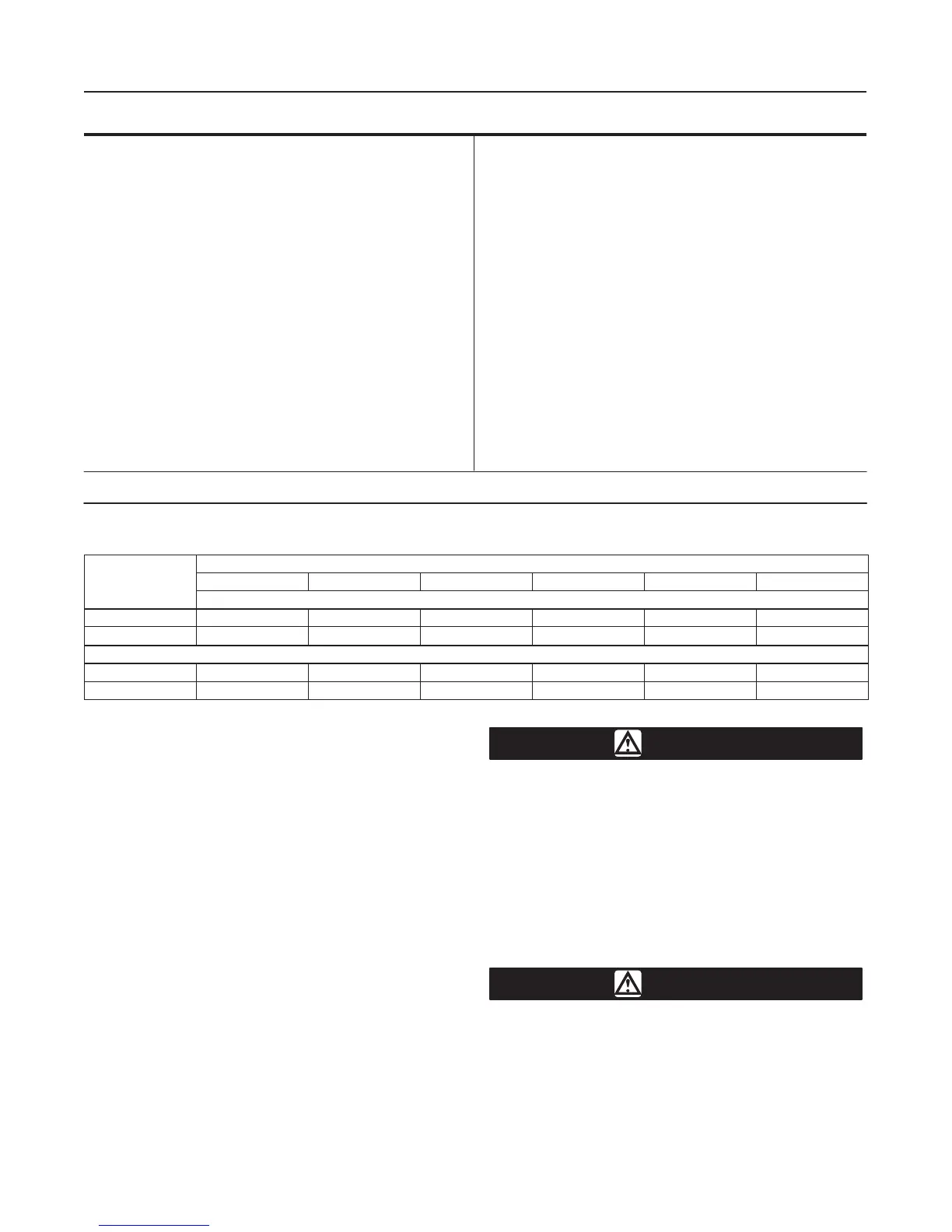

Table 1. Specifications

Maximum Inlet Pressures and Temperatures

(1)

If the valve nameplate shows an ANSI pressure-

temperature class, maximum inlet pressure and

temperature is consistent with applicable ANSI

class per ASME B16.34.

If the nameplate does not show an ANSI class, it

will show a maximum cold working pressure at

100_F (38_C) (for example, 3600, 6000, 9000, or

10,000 psi)

Maximum Allowable Pressure Drops

(2)

Flow up: Capable of full rated pressure drops

Flow down: See table 2 for pressure drop limits for

ceramic trim

Shutoff Classification Per ANSI/FCI 70-2

Standard: Class IV

Optional: Class V

Maximum Service Temperature

450_F (232_C)

Flow Characteristic

Equal Percentage

Flow Direction

Design D Valve: Flow up through the seat ring and

out past the valve plug

Design DA Valve: Flow in either direction

Approximate Weight

Design D: 75 pounds (34 kg)

Design DA: 100 pounds (46 kg)

1. Do not exceed the pressure or temperature limits in this manual and any applicable standard limitations.

2. The pressure-temperature limits in this manual and in any applicable standard limitations should not be exceeded.

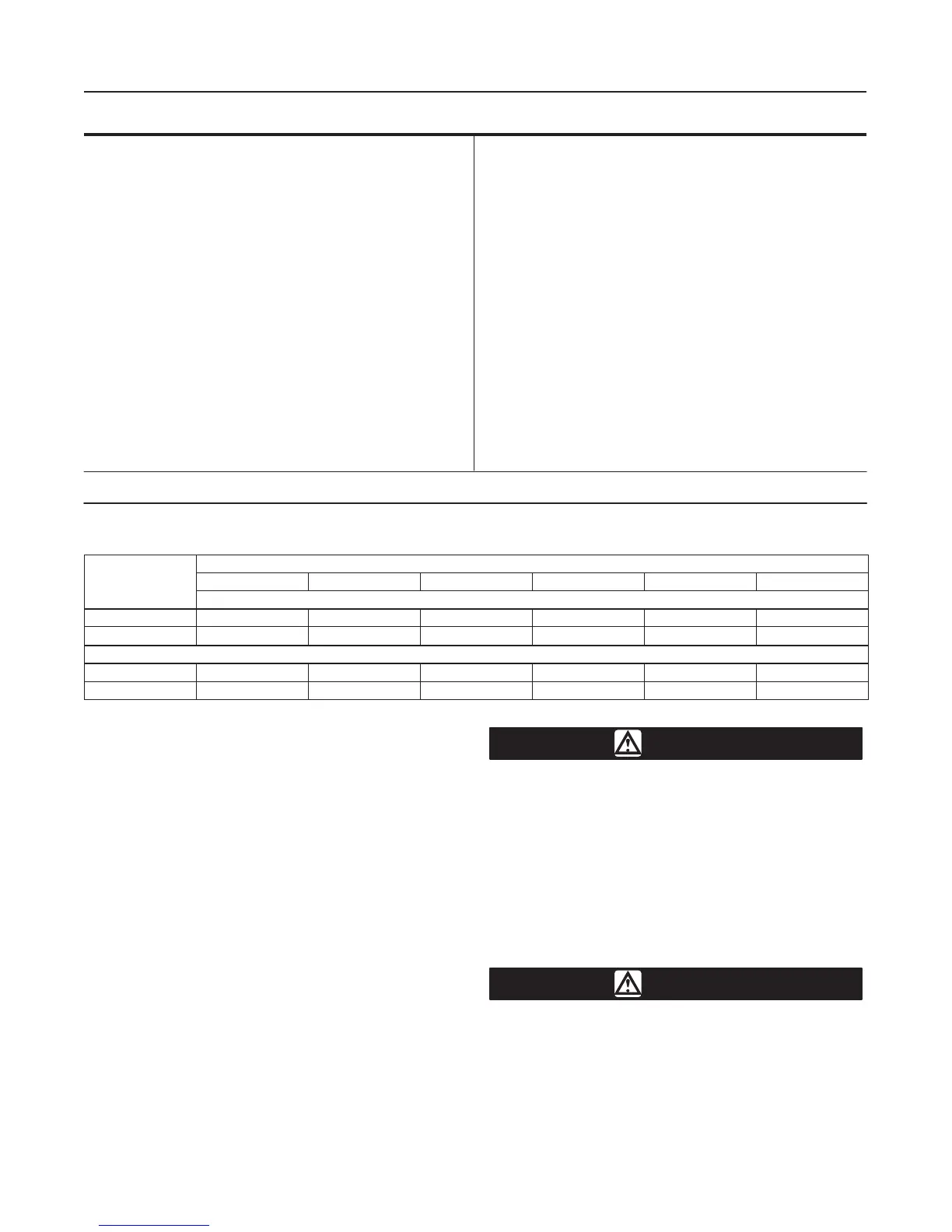

Table 2. Flow Down Pressure Drop Limits - Ceramic Trim Only

SEAT RING DIAMETER, INCHES (mm)

VALVE SIZE

1/4 (6.4) 3/8 (9.5) 1/2 (12.7) 3/4 (19.1) 1 (25.4) 1-1/4 (31.8)

Pressure Drop, psi

1 6000 6000 6000 2800 - - - - - -

2 10,000 10,000 10,000 6700 3800 2400

Pressure Drop, bar

1 414 414 414 193 - - - - - -

2 689 689 689 462 262 165

Description

The Design D globe-style (figure 1) and Design DA

angle-style (figure 4) valves are single-port, metal-

seated valves for high-pressure applications.

Specifications

Specifications for these valves are in table 1. Some of

the specifications for a given valve appear on a name-

plate, which is attached to the valve actuator or wired

to the valve assembly if the valve was purchased with-

out an actuator.

Ceramic Trim

Some types of ceramic trim, including the VTC (very

tough ceramic) variety, can create a spark under cer-

tain circumstances. When the edge of a ceramic part

is struck against a second ceramic part with enough

force, a spark can be created.

WARNING

Avoid personal injury and property dam-

age from ignition of process fluid

caused by sparks from ceramic trim.

Do not use ceramic trim where the pro-

cess fluid is unstable or if it is an explo-

sive mixture (such as ether and air).

Installation

WARNING

To avoid personal injury or property

damage resulting from the sudden re-

lease of process pressure or bursting of

parts, do not install the valve assembly

where service conditions could exceed

the limits given in this manual or on the

Loading...

Loading...