Design CAV4

3

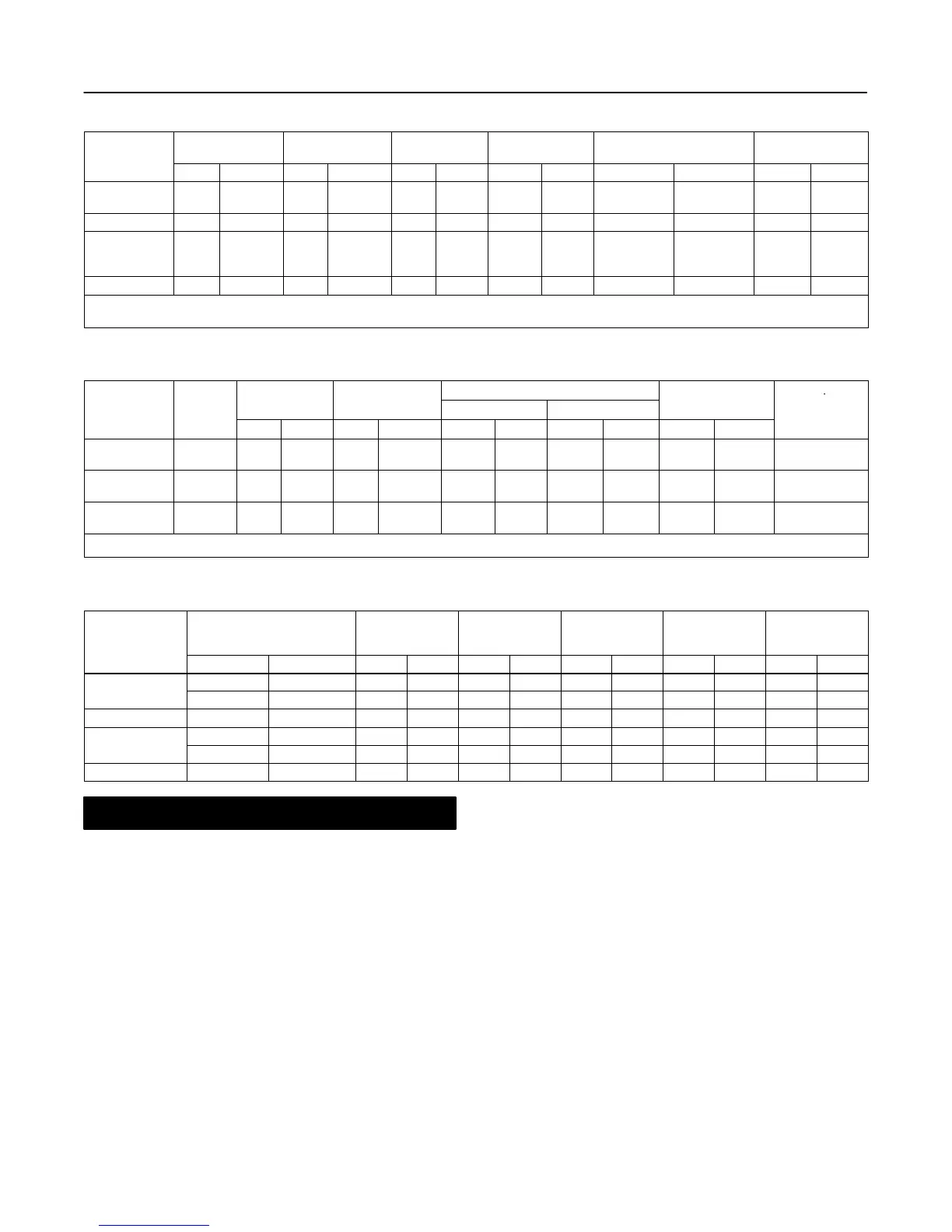

Table 2. Additional Valve Specifications

VALVE SIZE,

VALVE STEM

DIAMETER

YOKE BOSS

DIAMETER

TRAVEL

PORT

DIAMETER

PORT

CIRCUMFERENCE

UNBALANCE

AREA

(1)

INCH

mm Inch mm Inch mm Inch mm Inch mm Inch mm

2

Inch

2

2

19.0

38.1

3/4

1-1/2

(2)

91

127

3-9/16

5

38 1-1/2 38.1 1-1/2 119.6 4.71 4.3 0.17

3 19.0 3/4 91 3-9/16 51 2 55.6 2-3/16 174.5 6.87 6.6 0.26

4

19.0

25.4

69.8

3/4

1

2-3/4

(3)

91

127

178

3-9/16

5

7

64 2-1/2 69.9 2-3/4 219.4 8.64 8.1 0.32

6 31.7 1-1/4 127 5 & 5H 102 4 111.1 4-3/8 349.2 13.75 12.9 0.51

1. For seal ring and piston ring constructions. For stem-balanced construction, use port area of 11.4 cm

2

(1.77 inch

2

) for 2 inch valve and 38.3 cm

2

(5.94 inch

2

) for 4 inch valve.

2. Stem-balanced construction has 31.8 mm (1-1/4 inch) valve stem connection.

3. Stem-balanced construction has 50.8 mm (2 inch) valve stem connection.

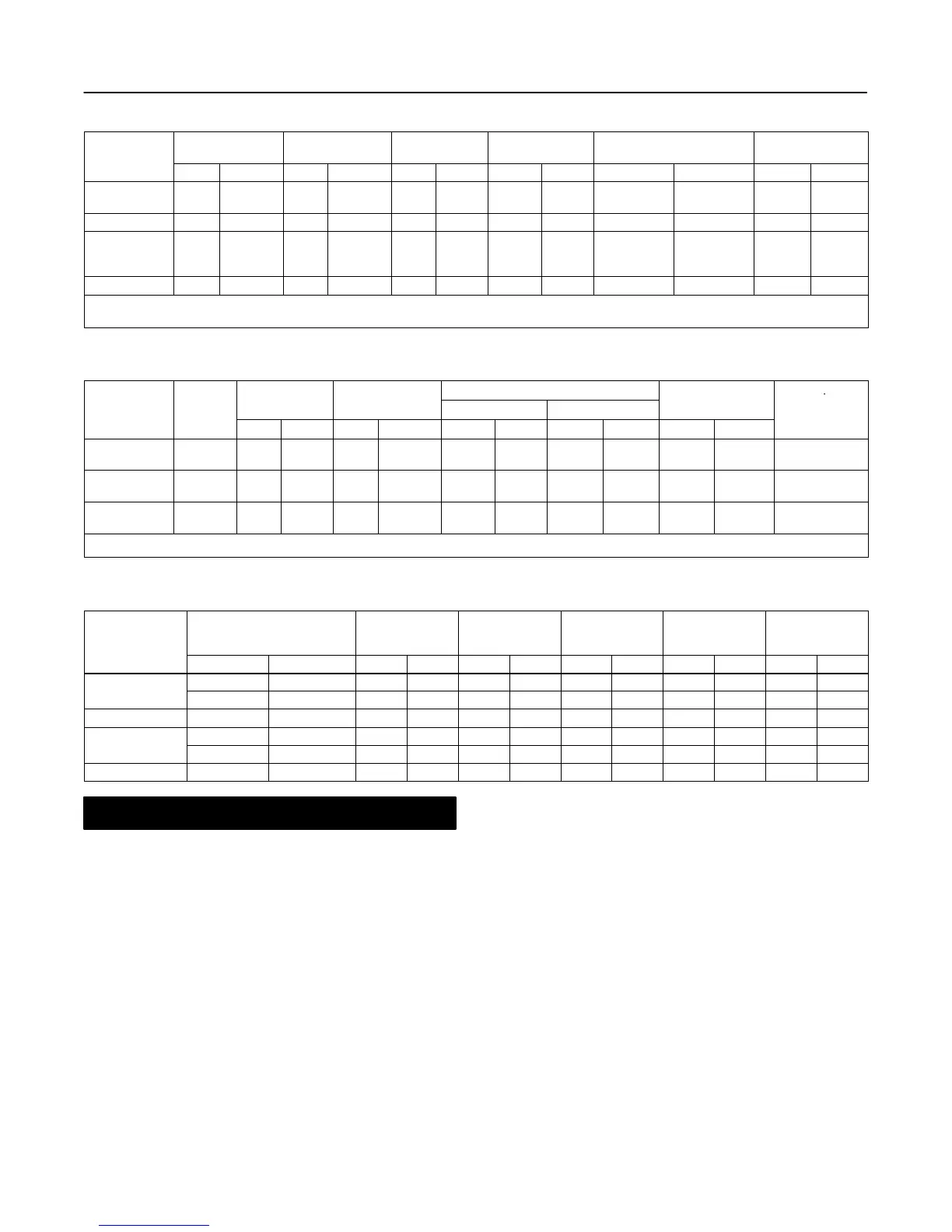

Table 3. Additional Valve Specifications for TSO (Tight Shutoff) Trim

MAXIMUM YOKE BOSS

PORT DIAMETER

PORT

C

V

VALVE SIZE,

TRIM

TRAVEL

SIZE

(1)

Nominal Actual TSO

CIRCUMFERENCE

REDUCTION

mm Inch mm Inch mm Inch mm Inch mm Inch

TRAVEL

(2)

2

Class

2500

38 1-1/2

91

127

3-9/16

5

38.1 1-1/2 38.1 1-1/2 119.6 4.71 0%

3

Class

2500

50.8 2 91 3-9/16 55.6 2-3/16 55.6 2-3/16 174.8 6.88 0%

4

Class

2500

64 2-1/2

91

127

3-9/16

5

69.9 2-3/4 69.9 2-3/4 219.4 8.64 0%

1. Consult the factory for larger yoke boss sizes.

2. This column lists the percent reduction of published maximum C

V

of the trim listed in the TRIM column.

Table 4. Approximate Weights

VALVE SIZE,

INCH

YOKE BOSS

DIAMETER

TOTAL

BONNET

ONLY

VALVE PLUG

AND STEM

ASSEMBLY

LOWER CAGE

ASSEMBLY

UPPER

CAGE

mm Inch Kg Lb Kg Lb Kg Lb Kg Lb Kg Lb

91 3-9/16 167 369 44 98 3 7 12 27 4 9

2

127 5 182 401 59 130 3 7 12 27 4 9

3 91 3-9/16 301 664 47 103 5 12 14 30 7 16

91 or 127 3-9/16 or 5 532 1172 127 280 12 27 37 82 12 27

4

178 7 554 1222 150 330 12 27 37 82 12 27

6 127 5 or 5H 1512 3334 240 530 44 98 84 186 54 120

CAUTION

When ordered, the valve configuration

and construction materials were se-

lected to meet particular pressure, pres-

sure drop, temperature, and controlled

fluid conditions. Do not apply any other

conditions to the valve without first con-

tacting your Fisher Controls sales office

or sales representative.

Trim parts, seals, and gaskets may be

damaged if post-weld buttweld heat

treatment is applied to valve areas other

than the end connections. If heat treat-

ment will be performed over the entire

valve body, seals and gaskets must be

removed. Valve plug seals may be re-

used; gaskets that are removed must not

be reused. Use new gaskets upon as-

sembly.

If hoisting the valve, be sure the hoist

used is capable of handling the weight

of the valve and actuator. Also, be sure

the sling does not damage the painted

surfaces, is positioned securely to pre-

vent swinging or slipping, and is posi-

tioned so as to cause no damage to tub-

ing or any accessories.

1. The valve must be installed so that the actuator is

positioned vertically above the valve body. This posi-

tion reduces the possibility of uneven wear on the

valve plug. Also, this position facilitates easier mainte-

nance and prevents stem binding due to actuator

weight.

Loading...

Loading...