Instruction Manual

D100397X012

ES Valve

July 2017

5

instructions. Figure 9 shows a typical HIGH‐SEAL Packing system. Figures 10, 11, and 12 show typical ENVIRO‐SEAL packing

systems.

If the valve has an ENVIRO‐SEAL bellows seal bonnet installed, refer to this manual. See the ENVIRO‐SEAL Bellows Seal and Bonnet

section for information on the bellows seal bonnet.

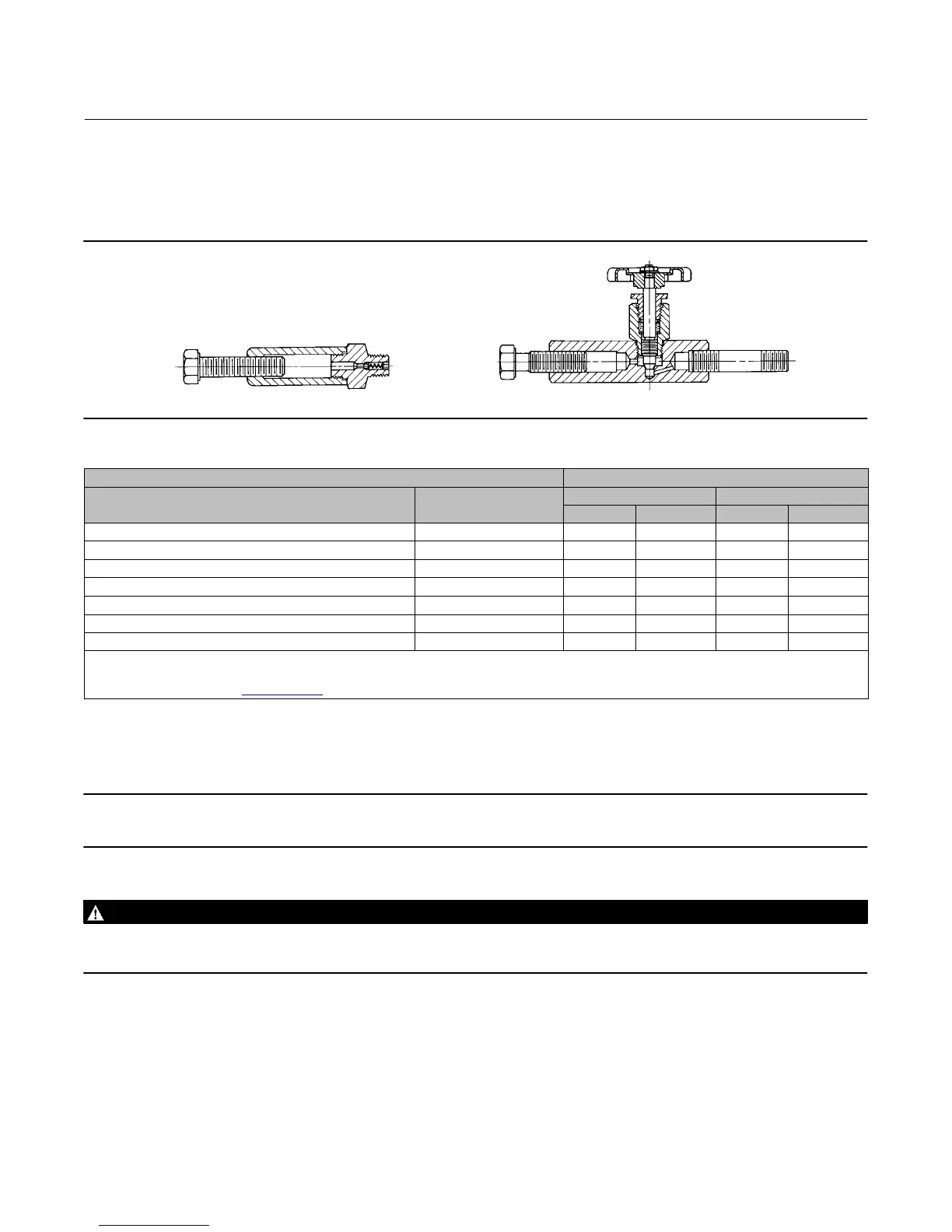

Figure 2. Optional Lubricator and Lubricator/Isolating Valve

LUBRICATOR LUBRICATOR/ISOLATING VALVE

10A9421‐A

AJ5428‐D

A0832‐2

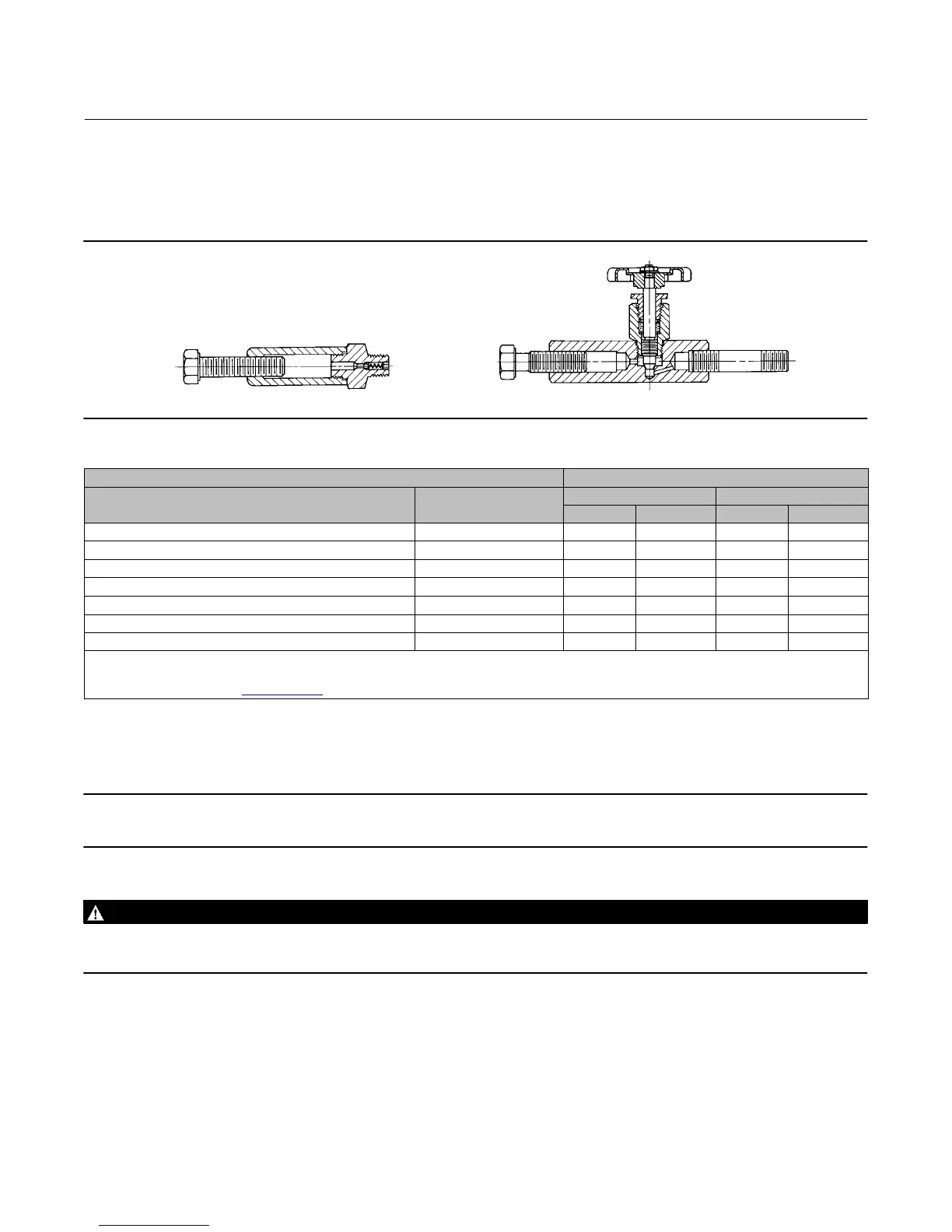

Table 3. Body‐to‐Bonnet Bolt Torque Guidelines

VALVE SIZE, NPS BOLT TORQUES

(1,

4)

ES EAS

SA193‐B7, SA193‐B8M

(3)

SA193‐B8M

(2)

NSm LbfSft NSm LbfSft

1‐1/4 or less 1 129 95 64 47

1‐1/2, 1‐1/2 x 1, 2, or 2 x 1 2 or 2 x 1 96 71 45 33

2‐1/2 or 2‐1/2 x 1‐1/2 3 or 3 x 1‐1/2 129 95 64 47

3, 3 x 2, or 3 x 2‐1/2 4 or 4 x 2 169 125 88 65

4, 4 x 2‐1/2, or 4 x 3 6 or 6 x 2‐1/2 271 200 156 115

6 ‐ ‐ ‐ 549 405 366 270

8 ‐ ‐ ‐ 746 550 529 390

1. Determined from laboratory tests.

2. SA193‐B8M annealed.

3. SA193‐B8M strain hardened.

4. For other materials, contact your Emerson sales office

or Local Business Partner for torques.

Packing Lubrication

Note

ENVIRO‐SEAL or HIGH‐SEAL packing does not require lubrication.

WARNING

To avoid personal injury or property damage resulting from fire or explosion, do not lubricate packing used in oxygen

service or in processes with temperatures over 260_C (500_F).

If a lubricator or lubricator/isolating valve (figure 2) is provided for PTFE/composition or other packings that require

lubrication, it will be installed in place of the pipe plug (key 14, figure 8). Use a good quality silicon‐base lubricant.

Packing used in oxygen service or in processes with temperatures over 260_C (500_F) should not be lubricated. To

operate the lubricator, simply turn the cap screw clockwise to force the lubricant into the packing box. The

lubricator/isolating valve operates the same way except the isolating valve must first be opened and then closed after

lubrication is completed.

Loading...

Loading...