Quick Start Guide

D103214X012

DLC3010 Digital Level Controller

February 2016

21

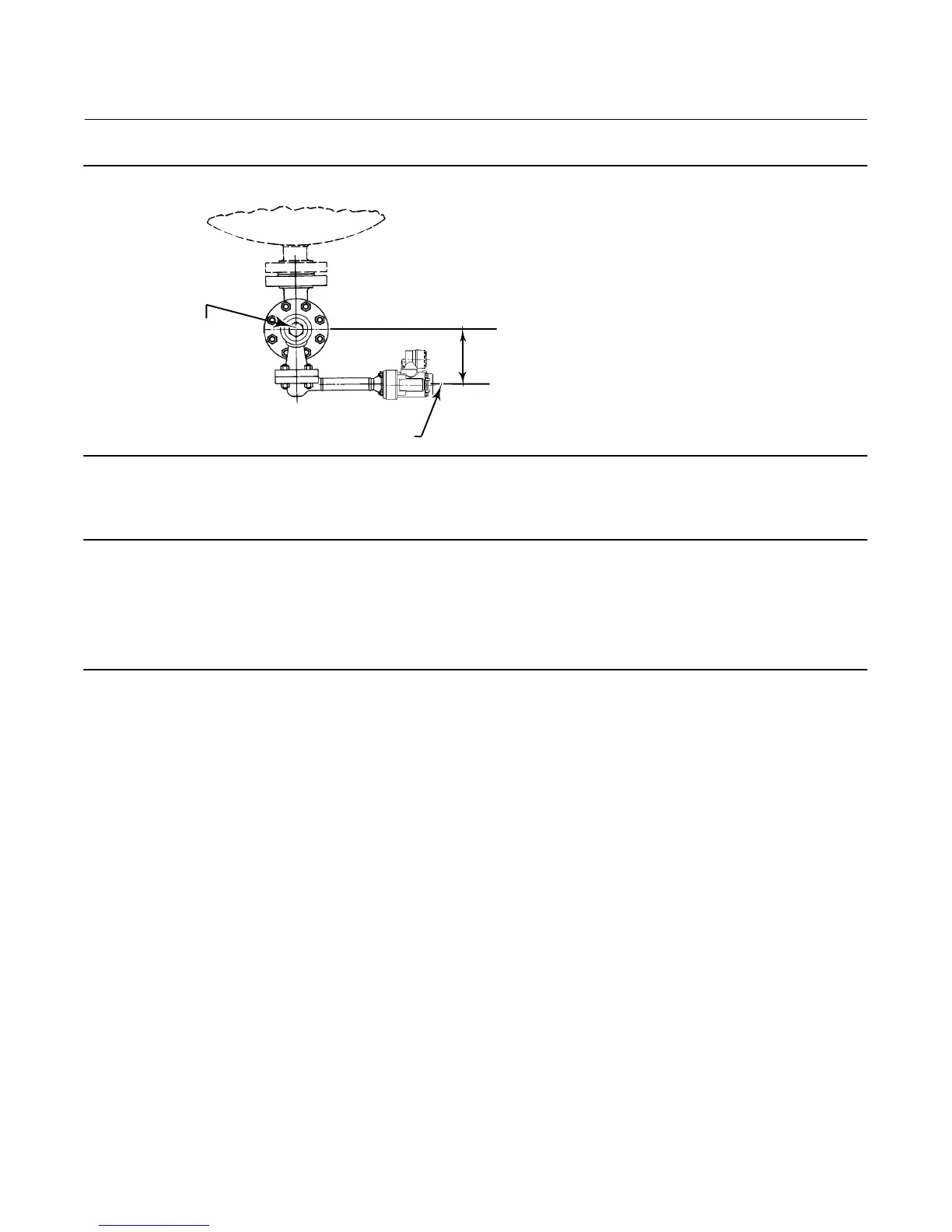

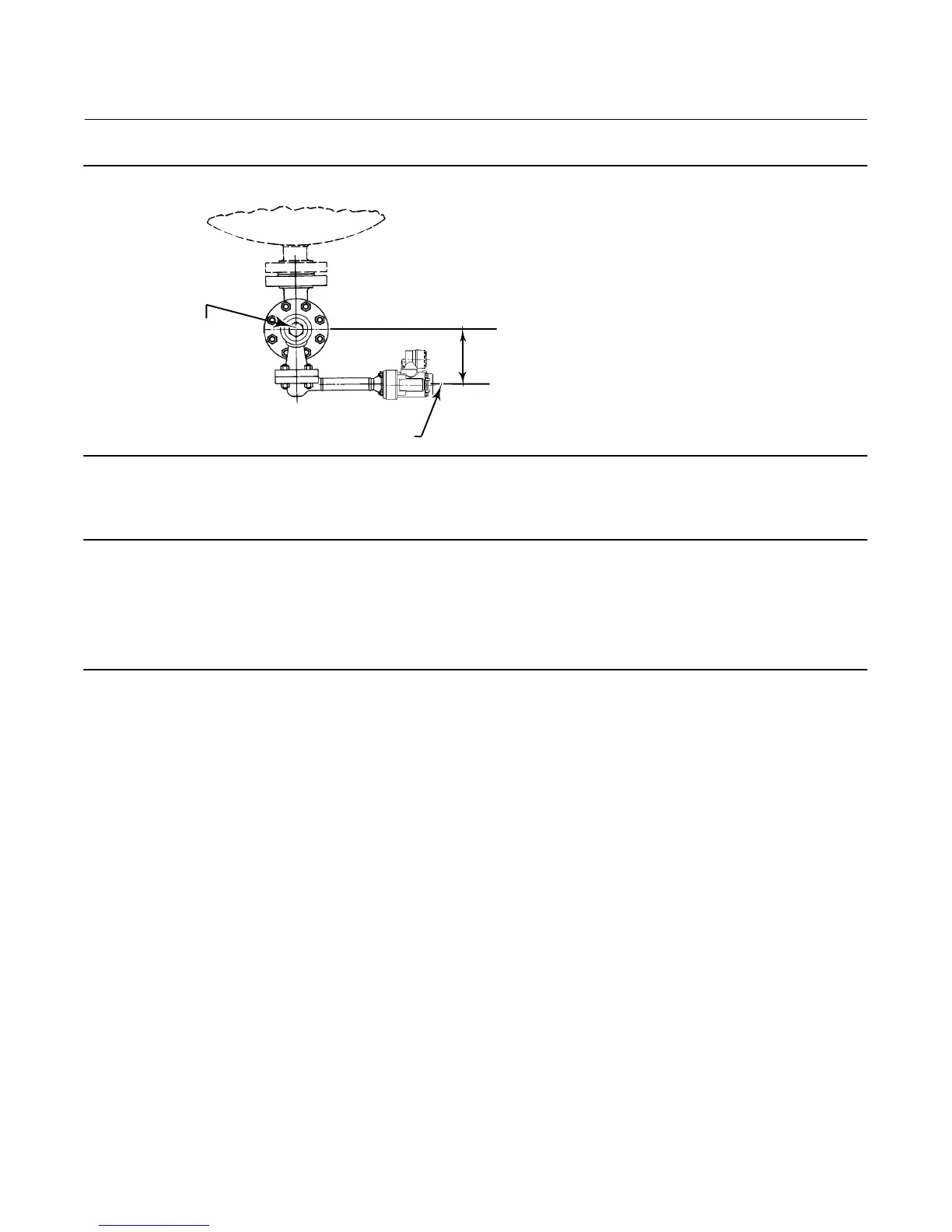

HORIZONTAL C

L

OF TORQUE TUBE

VERTICAL C

L

OF DISPLACER

MOMENT

ARM LENGTH

VESSEL

Figure 12. Method of Determining Moment Arm from External Measurements

E0283

4. Select the measurement application (level, interface, or density).

Note

For interface applications, if the 249 is not installed on a vessel, or if the cage can be isolated, calibrate the instrument with

weights, water, or other standard test fluid, in level mode. After calibrating in level mode, the instrument can be switched to

interface mode. Then, enter the actual process fluid specific gravity(s) and range values.

If the 249 sensor is installed and must be calibrated in the actual process fluid(s) at operating conditions, enter the final

measurement mode and actual process fluid data now.

a. If you choose “Level” or “Interface,” the default process variable units are set to the same units chosen for

displacer length. You are prompted to key in the level offset. Range values will be initialized based on Level Offset

and displacer size. The default upper range value is set to equal the displacer length and the default lower range

value is set to zero when the level offset is 0.

b. If you choose “Density,” the default process variable units are set to “SGU” (Specific Gravity Units). The default

upper range value is set to “1.0” and the default lower range value is set to “0.1”.

5. Select the desired output action: Direct or Reverse.

Choosing “reverse acting” will swap the default values of the upper and lower range values (the process variable values

at 20 mA and 4 mA). In a reverse acting instrument, the loop current will decrease as the fluid level increases.

6. You are given the opportunity to modify the default value for the process variable engineering units.

7. You are then given the opportunity to edit the default values that were entered for the upper range value (PV Value

at 20 mA) and lower range value (PV Value at 4 mA).

Loading...

Loading...