LIQUID-COUPLED HEAT EXCHANGER ECONET

®

Installation & Maintenance Manual

8

FläktGroup DC_9010GB 20180327_R0 Specifications are subject to alteration without notice

ECONET

®

ASSEMBLY AND INSTALLATION

COIL INSTALLATION

The coils are installed in the air handling units at the factory.

The coils must be connected as a counter-flow connection.

Warm against warm and cold against cold. All connections are

marked with labels.

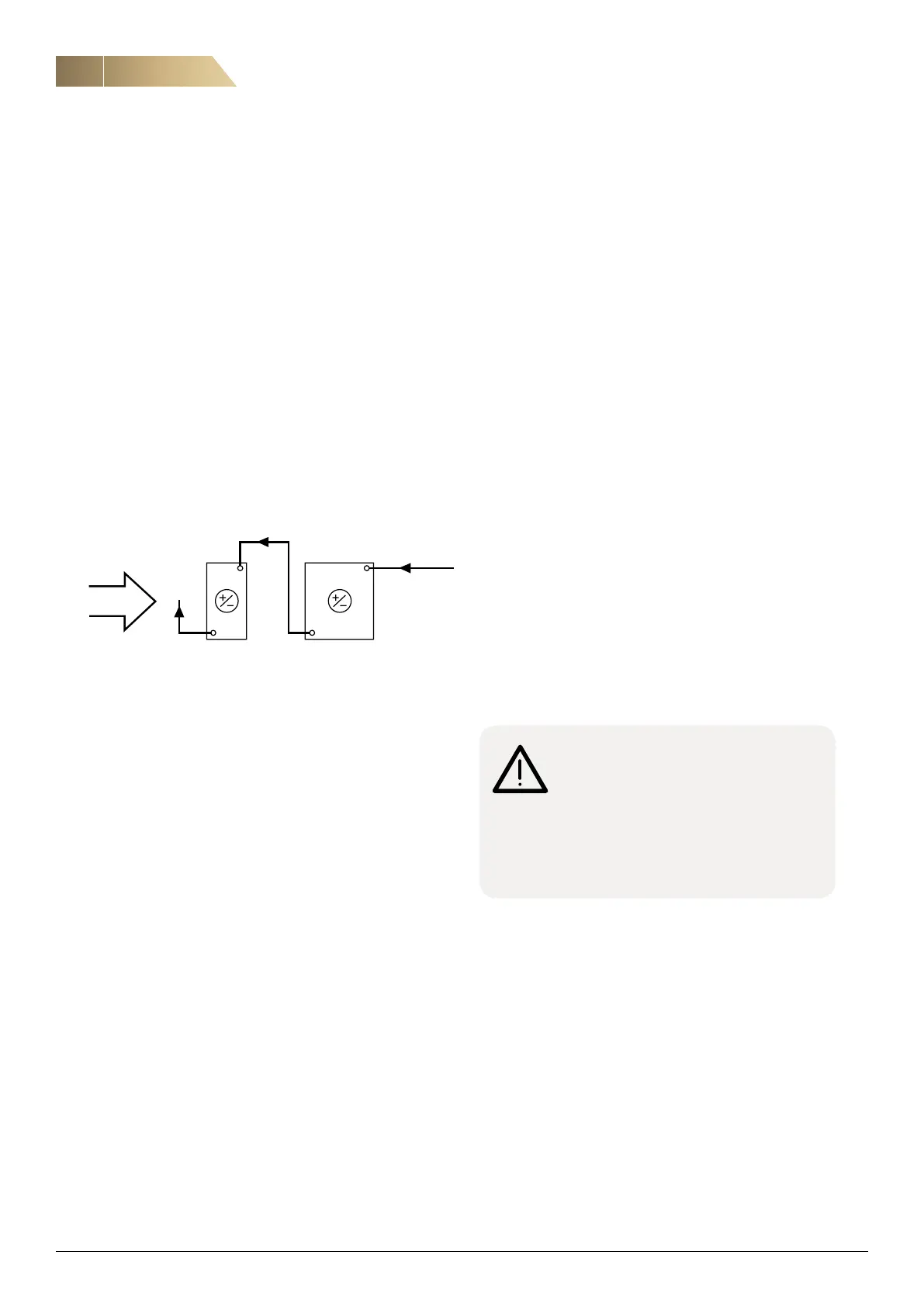

If a dry box solution is specified, the supply air coils are divided

into two coils, one before and the other after the supply air filter.

The supply air coils must be connected as a serial connection.

First to the main supply air coil (after the filter) and then as a

serial connection to the preheater coil (the coil before the filter).

PIPE INSTALLATION

Connection to the pipe system should be carried out by the

plumbing contractor. Installation normally includes:

– Installation of necessary components for connecting

an external energy source, as set out in the documentation.

The necessary components vary depending on the design of

the object. Examples of external components are:

Expansion vessel

Heat exchanger and valves for supplementary

heating/cooling

External shut off valves

Connection for filling

Automatic air purging valve combined with a manual

air purging valve

Air purging valves for micro bubbles

Filter

Charging equipment

Water trap

Anti-freeze liquid

– Installation of pipes between the pump unit, the exhaust air

coil and the supply air coil.

– Connecting the supply air and exhaust air coil.

– Filling of liquid and air purging of the pump before commis-

sioning.

– Air purging the system.

– Shut of valves for each coil.

If the exchanger package is delivered from FläktGroup:

Mounting and installation of the exchanger package to the

ECONET

®

pump unit, and connection of the external energy

sources, including necessary valves, etc. Please see separate

instructions for more specific installation details.

The Econet

®

must be connected to the pipe system so that ex-

pansion forces or the pipe system’s own weight do not impose

a load on the liquid connections.

The liquid connections are provided with signs for the inlet and

outlet.

Preheater

coil

Supply air

Main supply

air coil

Director

of the flow

To

exhaust

coil

Make sure that all inspection doors can be opened after the

pipework is installed.

Important!

– Hold the pipe connections steady with a

pipe wrench when tightening external pipes.

– Use flax (hemp) and paste for sealing

the connections.

– Use sealings suited for anti-freeze liquids,

such as ethylene glycol mixtures.

Loading...

Loading...