7

LIQUID-COUPLED HEAT EXCHANGER ECONET

®

Installation & Maintenance Manual

7

FläktGroup DC_9010GB 20180327_R0 Specifications are subject to alteration without notice

ECONET

®

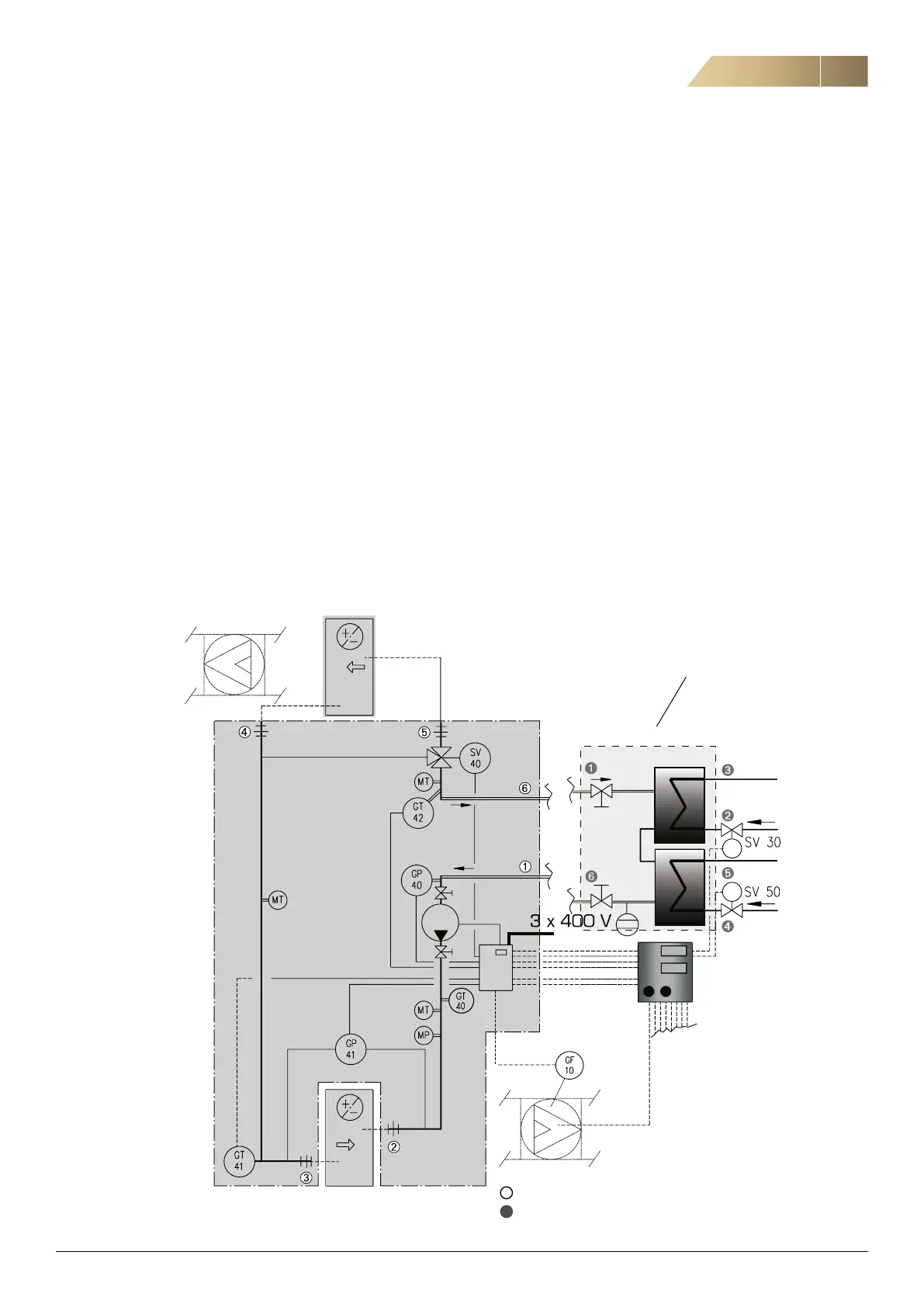

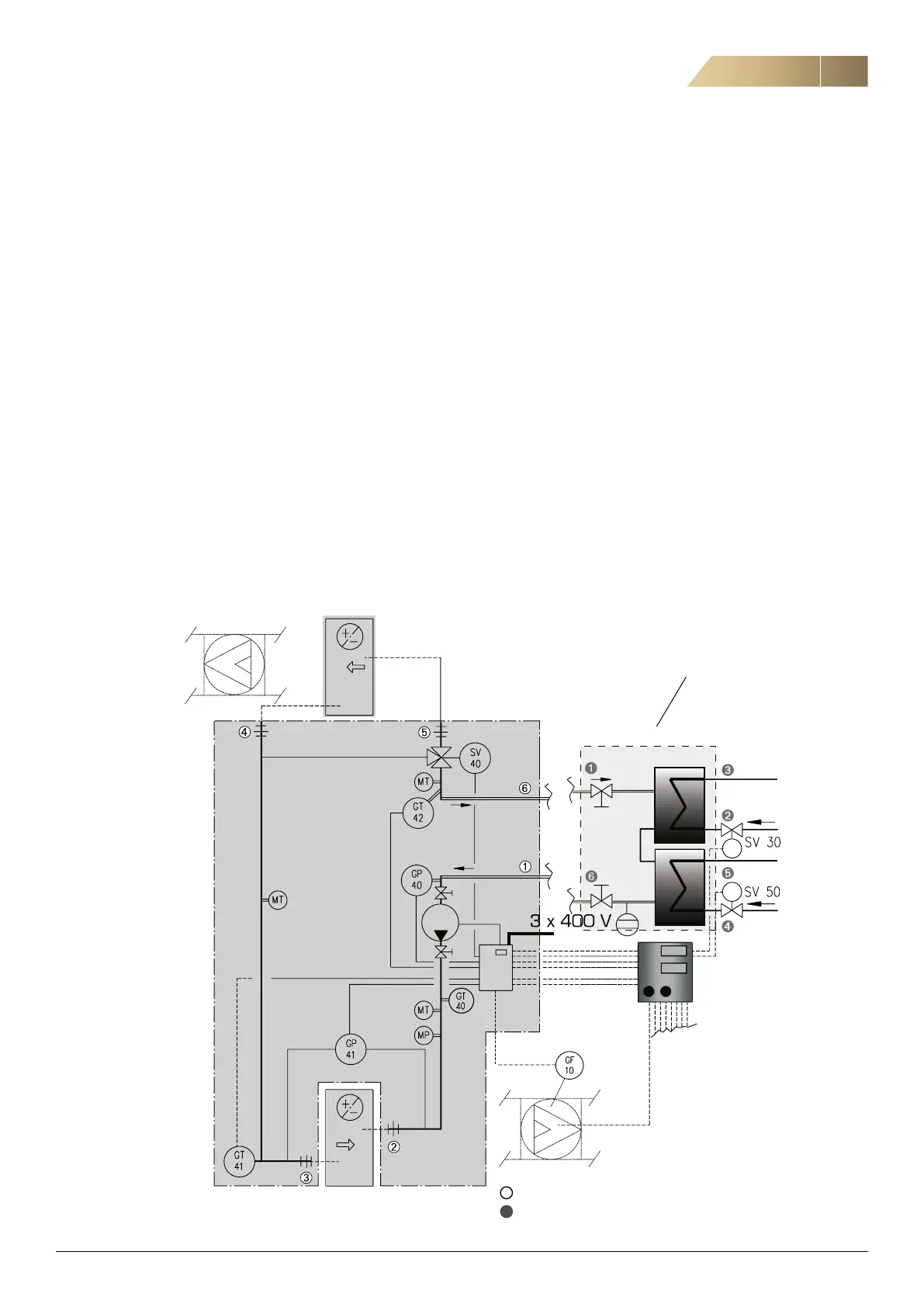

ASSEMBLY AND INSTALLATION

UNPACKING

INSPECTION OF DELIVERED EQUIPMENT

– Check for signs of transit damage.

– Check that the product codes on the rating labels conform to

your requirement.

– Check the delivered components against the bill of material.

– The code for the pump unit (STAZ-74-…) can be found on the

ECONET

®

pump unit.

INSTALLATION INSTRUCTION

The following must be carried out on site by the plumbing/

automation and electrical contractors.

– Assembly of the pump unit, installation of pipes from the

exhaust and supply air coils, connection to the exhaust air

and supply air coils.

– Installation of necessary components for connecting an

external energy source, as set out in the documentation.

– Filling and air purging of system.

– Power supply to the ECONET

®

frequency inverter.

– Connection between the ECONET

®

frequency inverter and

the controller for the AHU.

– Wiring between the air flow sensor (supply air) and the

ECONET

®

frequency inverter.

OPTION

– Commissioning of the ECONET

®

system.

– Controls for AHU, SV 30, SV 50, etz.

= Pipe connection: ECONET

®

= Pipe connection: Exchanger package

(EQRZ-05 ECONET

®

Exchanger Package, see separate manual).

Loading...

Loading...