4 Trouble shooting and fault finding

Notes: The following operations must be performed by qualified electricians with valid certifications. Before maintenance,

you are suggested to contact local distributor to verify qualification.

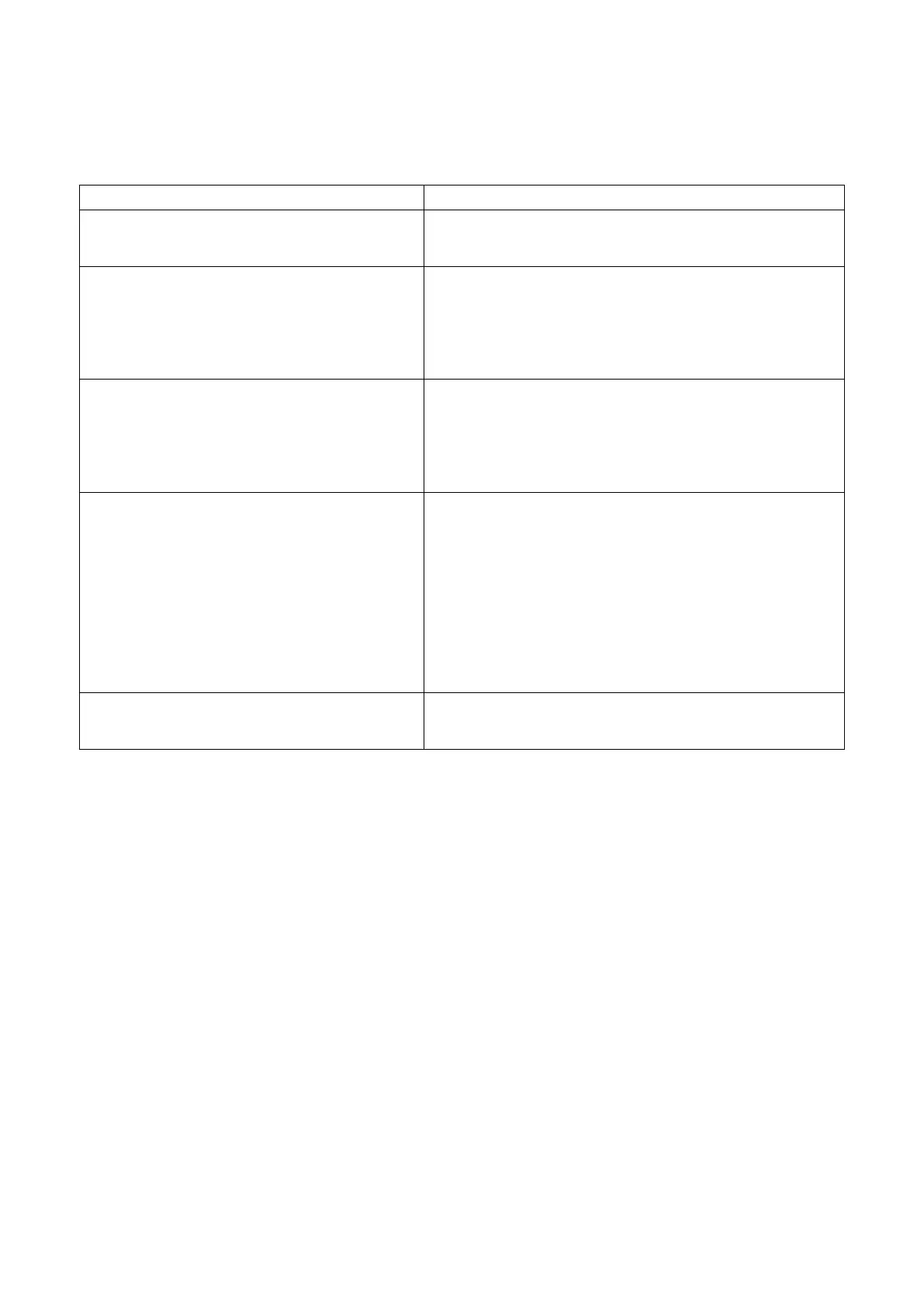

Faults Resolvable Methods

Switch indicator is on,fan is not working,

control knob is out of work.

Over voltage protection is working. Close machine then

Open it again after several minutes.

Switch indicator is lit,fan is working.

press control knob of torch, there is no HF

arc-striking sound and electromagnetic valve is not

working.

Check if torch is open circuit.

Check if control knob of torch is damaged.

Part of assistant power of top board is damaged and there is

no DC 24V output.

Switch indicator is lit,

fan is working.

press control knob of torch, there is no HF arc striking

sound and inter red diode is lit.

Check if MOS or IGBT of top board is damaged (driver

mould is damaged).

Rising transformer of bottom board is damaged.

Control mould is damaged.

Switch indicator is lit,

fan and electromagnetic valve are working,

there is no sound of HF

arc-striking and inter red diode is not lit.

here is some trouble in part of arc-striking, such as:

It is too far between discharge tip or there is adhesion in

discharge tip.

Primary coil of arc-striking transformer is damaged or poor

contact.

Check if four times voltage rectifier diode is stricken.

Check if HF electric capacity 102/10KV is leaking.

Relay is damaged.

Other of machine is normal, but arc is not be stricken

when it is be operating.

Input voltage is too low.

Pressure of air compressor is too high or too low .

Even the machine comes up with abnormal phenomenon such as cutting unable, arc unstable or bad welding effect, it is

still early to judge that there is malfunction on the machine.

The above-mentioned abnormal phenomenon may be caused by some reasons.

For example:

tight parts loosen,forgetting to switch on, wrong set up, cable broken and gas rubber pipe cracked, etc. Therefore, please

test and inspect these factors before deliver it back to the factory because a large number of troubles may be easily

solved probably.

5 Daily maintenance and checking

5.1 Daily maintenance

Remove dust regularly with dry compressed air. If the cutting machine is used in surroundings with heavy smoke and

polluted air, it is necessary to remove dust at least one time one month.

The pressure of compressed air shall fall to required level to prevent damage to small components in the machine.

Examine inside electric joints and ensure perfect contact (Especially plugs and sockets). Fasten the loosing joints. In

case of oxidation, remove oxide film with sand paper and connect again.

Prevent water from entering into the machine and prevent the machine from getting moist. If any, blow and dry.

Measure the insulation with megohmmeter to make sure it is qualified to use.

If the cutting machine is not used for a long time, pack the machine in original package and store in dry surroundings.

Loading...

Loading...