Output cable connection

Earth cable is connected to positive terminal of front panel then tighten it.

Make sure copper screw of another end of torch is connected to gas-electrify integration terminal then tighten them

clockwise relation (prevent from leaking gas). (Refer to 2.3)

Operation

(1) Open the power switch; make the power switch is in “on” position . Screen will show the current volume.

(2) Adjust the gas pressure and make it is adequate to machine, open the valve of pressed air.

(3) Make sure cutting current is adequate to machine according to thickness of cutting piece.

(4) Press the control knob of torch, electromagnetic valve is starting, it can be heard and burner of torch should flow out

gas (Burner of low frequency cutting machines or pilote-arc cutter should spurt fire)

(5) It is 1mm from copper tip to work piece (if it is arc-supporting cutter.),It is 3-5mm from copper tip to work piece (if it is

burner of low frequency cutting machines or pilote-arc cutter ).knob of torch and burn and strike arc,sparks of HF arc

striking will diminished immediately. User can begin to cut.

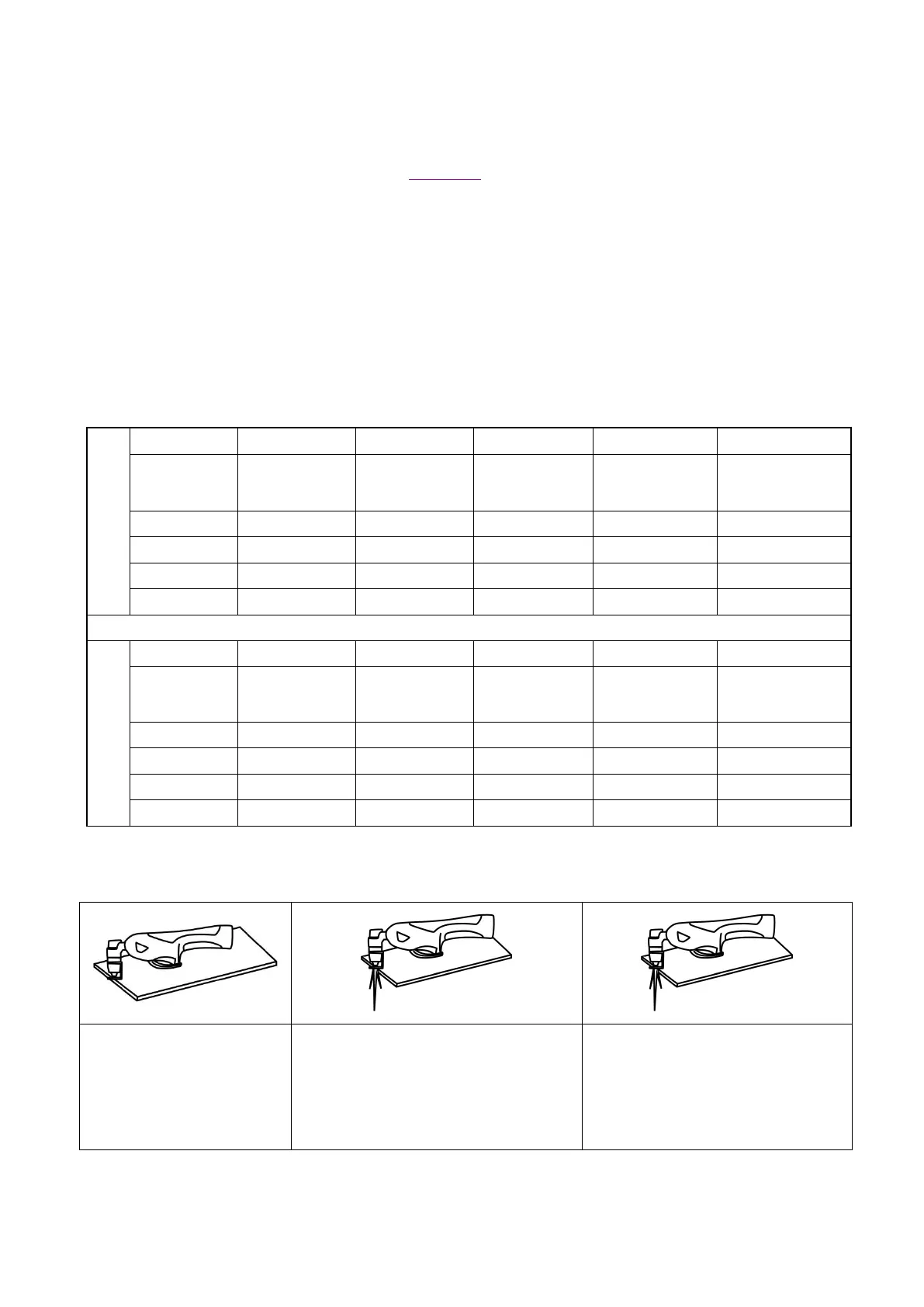

Adjust air pressure and Current

1

Input 240V 20Amps 35Amps 40Amps 45Amps 55Amps

Air pressure

30-70

(

PSI)

0.21-0.49(MPa)

30-70

(

PSI)

0.21-0.49(MPa)

30-70

(

PSI)

0.21-0.49(MPa)

30-70

(

PSI)

0.21-0.49(MPa)

30-70

(

PSI)

0.21-0.49(MPa)

Thickness (Fe) 5mm(13/64in) 8mm(5/16in) 10mm(25/64in) 15mm(19/32in) 20mm(3/4in)

Thickness (Ss) 5mm(13/64in) 8mm(5/16in) 10mm(25/64in) 15mm(19/32in) 20mm(3/4in)

Thickness (Al) 1mm(3/64in) 3mm(1/8in) 4mm(5/32in) 5mm(13/64in) 6mm(15/64in)

Thickness (Cu) 2mm(5/64in) 3mm(1/8in) 4mm(5/32in) 5mm(13/64in)

2

Input 120V 20Amps 30Amps 35Amps

Air pressure

30-50

(

PSI)

0.21-0.35(MPa)

30-50

(

PSI)

0.21-0.35(MPa)

30-50

(

PSI)

0.21-0.35(MPa)

Thickness (Fe) 5mm(13/64in) 8mm(5/16in) 12mm(1/2in)

Thickness (Ss) 5mm(13/64in) 8mm(5/16in) 12mm(1/2in)

Thickness (Al) 1mm(3/64in) 2mm(5/64in) 3mm(1/8in)

Thickness (Cu) 1mm(3/64in) 2mm(5/64in)

3.3 Start Cutting

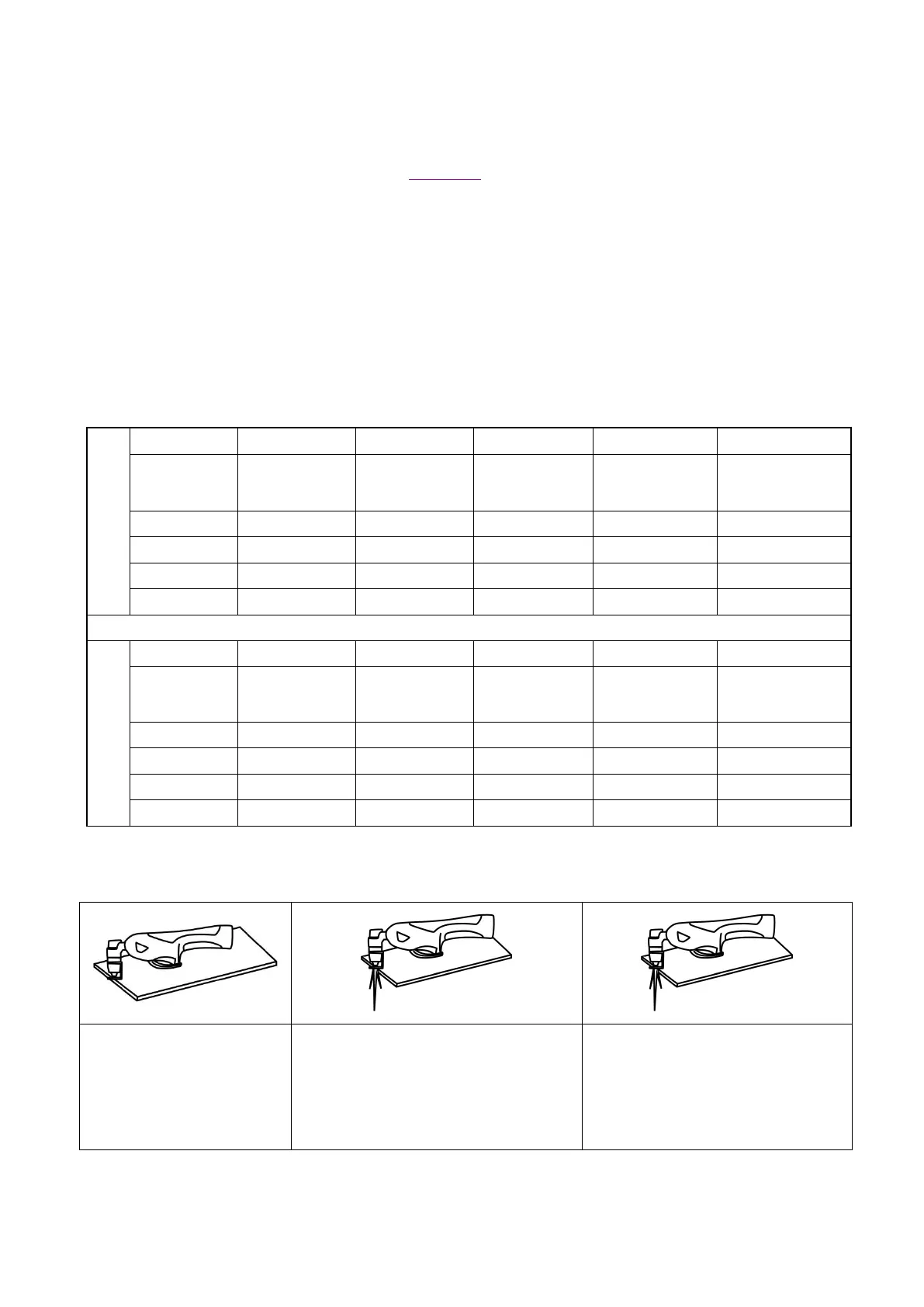

3.3.1 Edge cutting

Keep the torch vertical at the

edge of the workpiece. Keep

your wrist steady and ready to

start cutting

Pull the trigger to start the arc ,The cutting

arc will initiate when the torch tip is close

enough to the work Piece. Start cutting on

the edge until the Arc has cut completely

through.

fast speed will lead to incomplete cutting,

and arc blowback is easy to damage the

device. Too slow speed will lead to

excessive scum and cutting gap.

Loading...

Loading...