develops a pit in the end of the electrode, when the pit becomes too much poor quality cuts will result

and necessitate replacement of the electrode.

7 Air quality,

Air

pressure

and

volume

Compressors take in air at atmospheric pressure and increase the pressure and store it in a tank.

Moisture that forms in air lines has a tendency to condense into larger drops when the air pressure

decreases as it is entering the plasma torch. When these droplets enter into the high temperatures in

the plenum of the torch, they immediately break down into oxygen and hydrogen, which alters the

normal chemical content of air in the torch. These elements will then dramatically change the plasma

arc which causes the torch consumable parts to wear very quickly, alters the shape of the nozzle

orifice, dramatically affecting cut quality in terms of edge squareness, dross formation, and edge

smoothness.Air pressure, flow rate and air quality are critical to quality plasma cutting and consumable

life span.Usually air pressure is preset at 60 psi . The volume capacity of your compressor is important,

If you are doing a lot of cutting, cutting thick plate (same air consumption but slower cut speeds =

longer cut time) then choose a compressor at 1.5 to 2 times the plasma system requirement.

3.4 Hand torch cutting Show

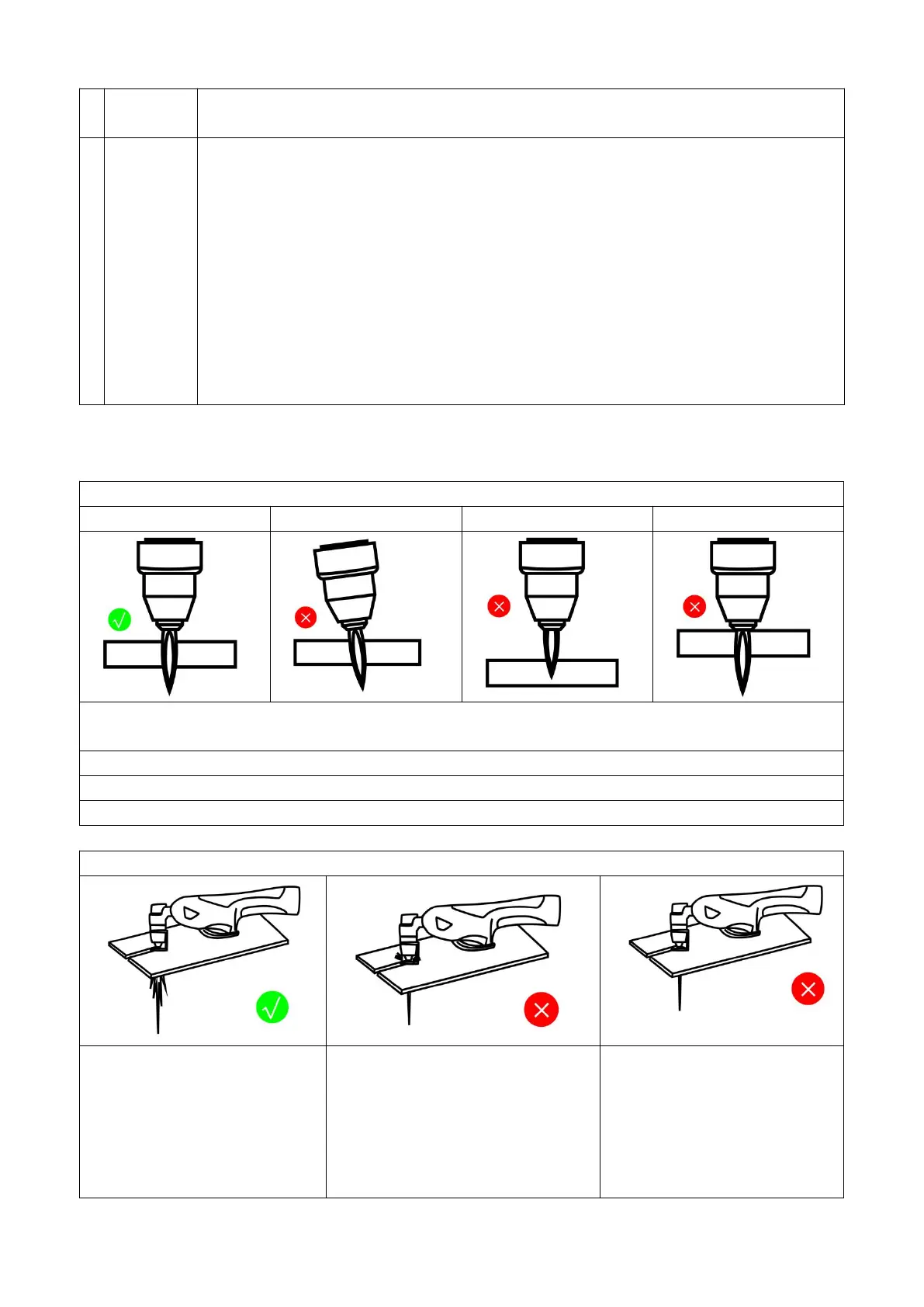

Torch tip height & position

① ② ③ ④

①

The correct torch height and right angle shall be consistent with the minimum slope and equal slope of the material, so

as to ensure good cutting effect and prolong the service life of consumables.

②

Torch angled to the material unequal bevel, one side may be excessively beveled.

③

Torch height too high, plasma stream may not cut all the way through the material.

④

Torch height too low. Tip may contact the work piece and short out or damage the tip.

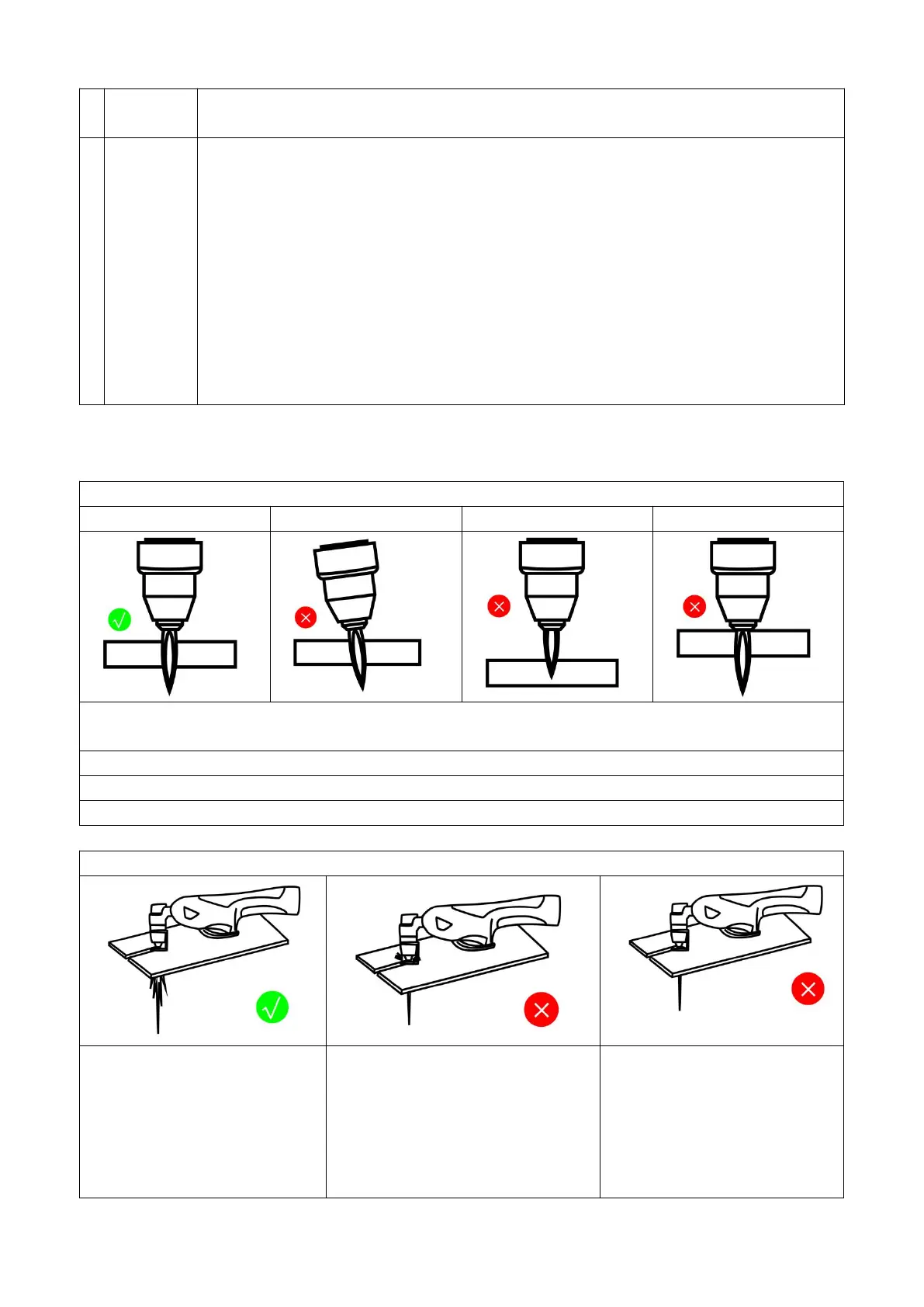

Speed and Amperage

When cutting, select the appropriate

current and pushing speed according

to the material and thickness of the

workpiece to ensure that the spark

are exiting from the bottom of the

workpiece

If the spark comes out from the top of the

workpiece, it means that the workpiece

has not been completely cut, because the

torch moves too fast or the current is set

too low.

If the spark passes vertically through

the workpiece, it indicates that the

workpiece has been completely cut

off and the torch is cutting air

because the torch moves too slowly

or the current setting is too large

Loading...

Loading...