INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F7000 / 8000 Series Rev. V

Pilot-Operated Safety Relief Valve Page 20 of 41

25) Assemble the pressure adjustment (PA) screw and lock nut into the top of the bonnet.

26) Attach the cap to the PA screw, but do not tighten.

27) Install vent / bug screen into bonnet, ensuring that the male NPT end does not contact the spring.

Install the inlet screen into the body.

28) Mount the face seals onto the external mounting face of the body.

29) The pilot valve is now completely assembled and ready to be set per Section 5.0.

30) If applicable, install lockwire and lead seal between PA screw cap, bonnet, and proportional band

screw. Repair tag may be attached to wire.

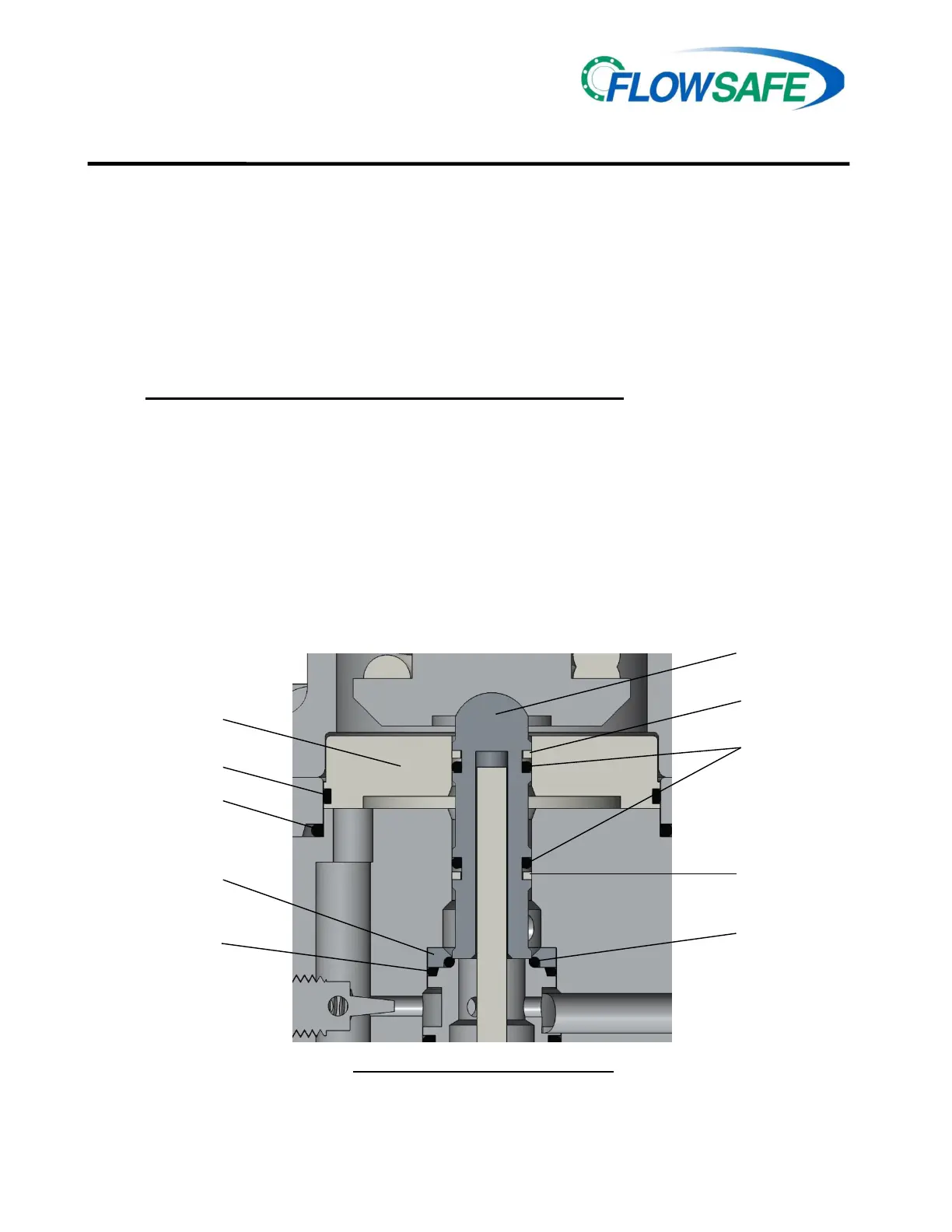

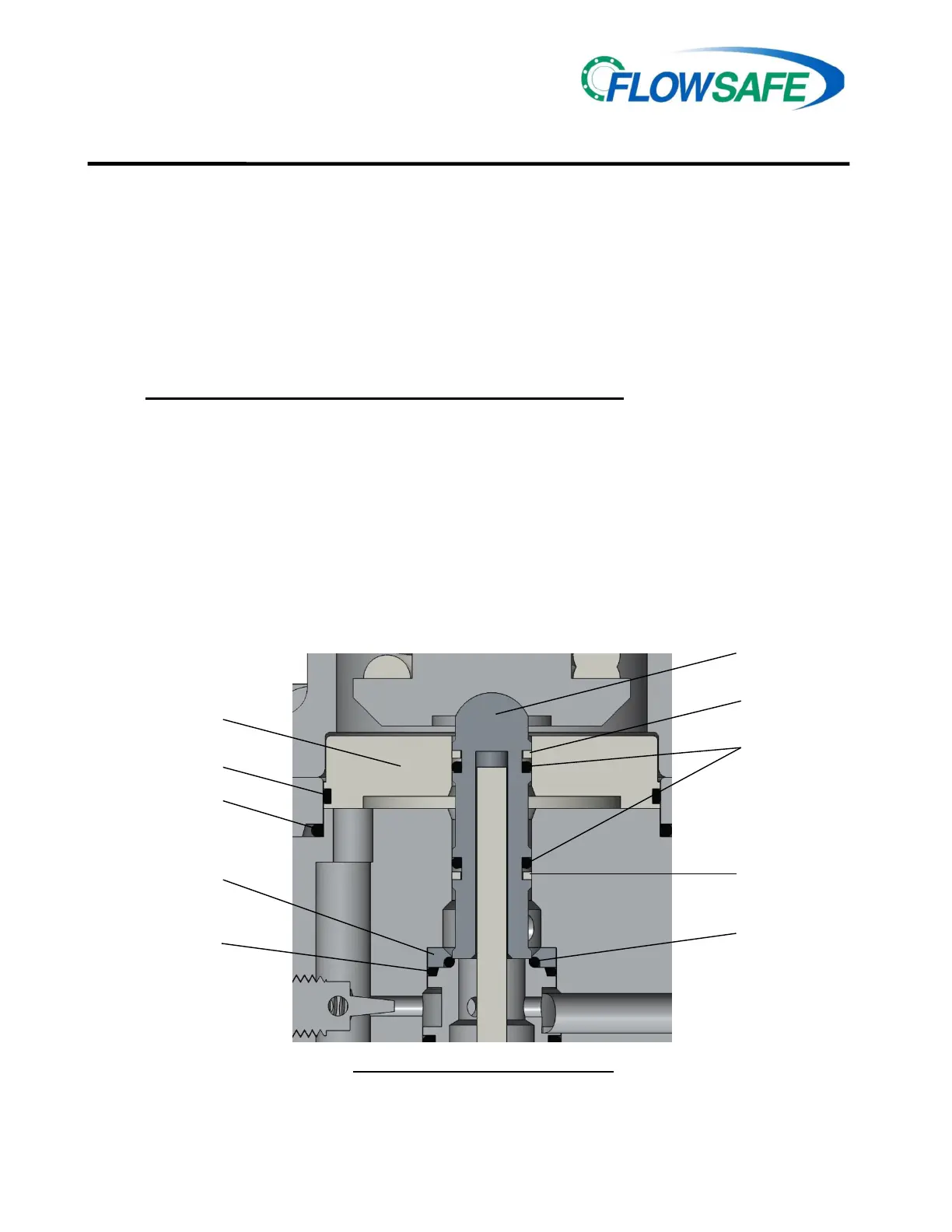

4.4 F300 PILOT VALVE, PISTON-STYLE (501 to 6000 psig) (See Illustrations below and on

Page 21)

A. F300 (Piston-style) Disassembly

CAUTION: It is extremely dangerous to attempt to disassemble any valve while it remains in

service with incoming line pressure.

1) Remove the pilot valve from the main valve, or safely block the incoming pressure before

disassembling the valve and performing maintenance.

2) Unscrew the pressure adjustment (PA) screw cap from the PA screw. Loosen the lock nut.

3) Loosen, but do not remove the PA screw from the bonnet.

4) Further disassembly can proceed in the reverse order from the assembly instructions on Page 22.

5) Replacement soft goods are listed in Section 8.0 of this manual.

See Section A-A on Page 18 for Backflow Preventer (BFP) details

UPPER

UPPER PISTON

BACKUP

RING

ADAPTER

BACKUP

RING

ADAPTER SEAL

SUPPORT

RING SEAL

SEAT RETAINER

NOZZLE

SLEEVE SEAL

F300 PILOT VALVE, HP PISTON-STYLE

(501 - 6,000 PSIG)

SEE FULL ASSEMBLY ON PAGE 22

Loading...

Loading...