INSTALLATION, OPERATION, &

MAINTENANCE MANUAL

TITLE: F7000 / 8000 Series Rev. V

Pilot-Operated Safety Relief Valve Page 6 of 41

2.2 SERVICE ENVELOPE

1

Confirm low-temperature applications with factory. Some O-ring seated valve configurations

have had cryogenic qualification testing performed down to -261°F (-163°C).

2

Pilot valve MAWP’s: 740 psig (F100); 6000 psig (F200, F300, & F500)

2.3 STORAGE AND HANDLING

A. STORAGE

Prior to installation, Flow Safe pressure relief valve assemblies and parts should be stored in a clean, dry

environment if possible. Inlet and outlet connections should remain covered until the item is ready for

installation.

For outside storage, protection from the elements is recommended particularly if plugs and flange covers are

not weather-tight. Exposed carbon steel surfaces should remain coated with a suitable rust inhibitor until the

assembly is ready for installation.

Even though elastomers and lubricants in the relief valve typically have a long shelf life and can be used in

environments down to -40

o

F/

o

C, operability of the main piston should be checked before placing the valve in

service after extended storage. See Section 2.4.

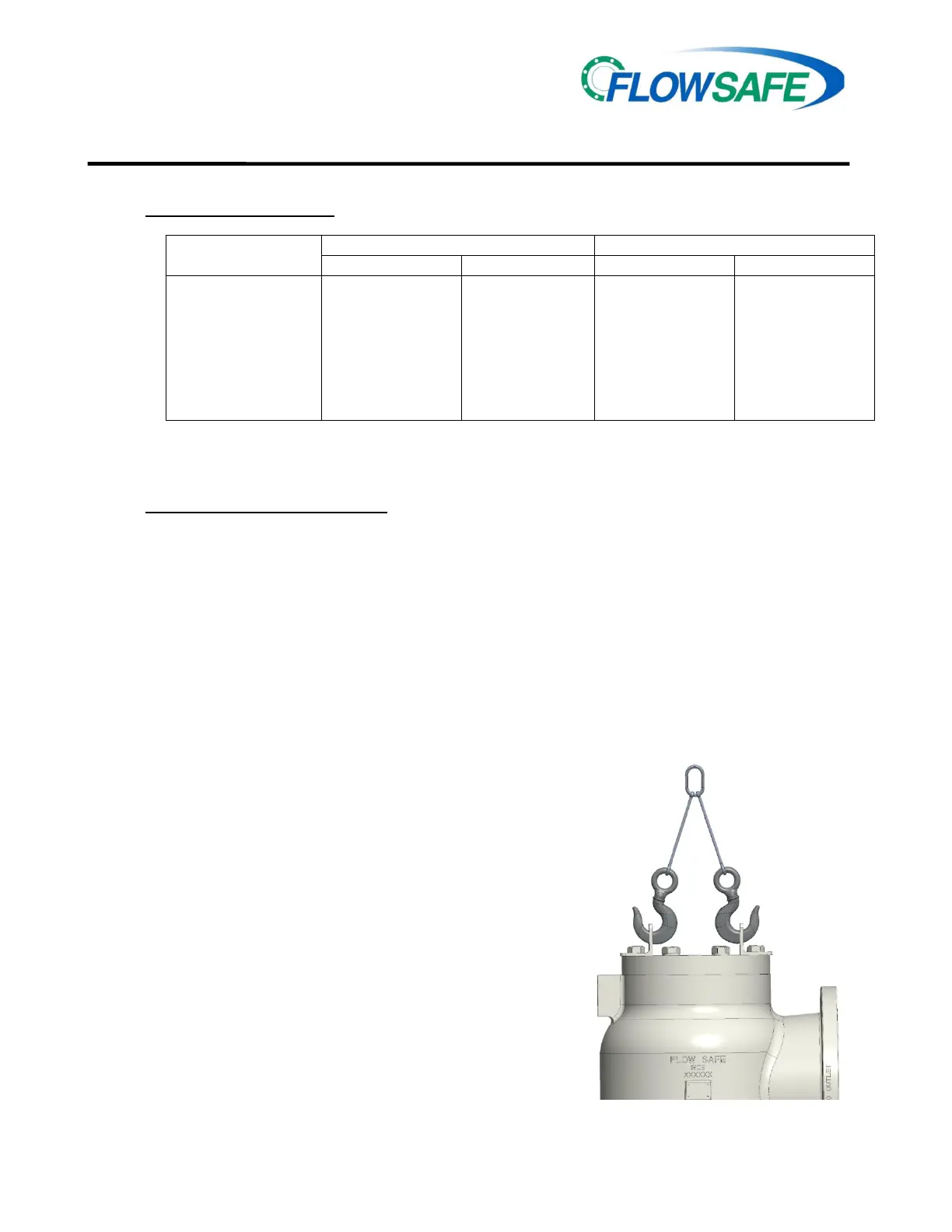

B. HANDLING AND LIFTING

Flange facings and other gasket sealing surfaces

shall be isolated from contact with other hard

objects through the use of cardboard or other soft

materials. Placing flanged surfaces directly on

wooden skids should be avoided due to possible

contact with nails.

Valve assemblies shall be lifted only from installed

lifting lugs or brackets, provided on all valves 2” x

3” and larger or with heavy flanges or accessories.

Smaller valves can be carried by hand (by holding

the main body and not tubing or other fittings).

When two lifting lugs are provided, generally on

valve assemblies 4” x 6” and larger, the load must

be balanced by use of a sling (chain, web, or

rope). See diagram below. All hooks, slings, and

other lifting devices shall be rated for the valve

assembly weight as identified by project drawings,

shipping documents, or scales used at receiving.

o

o

SET PRESSURE, psig (barg)

1

2

-30 (-34) 275 (135) 15 (1) 6000 (413)

® -30 (-34) 400 (204) 15 (1) 6000 (413)

-65 (-54) 225 (107) 15 (1) 6000 (413)

-65 (-54) 325 (163) 15 (1) 6000 (413)

® -423 (-252) 400 (204) 15 (1) 1000 (69)

Kel-F

-423 (-252)

0 (-18)

400 (204)

525 (273)

1000 (69)

3000 (207)

3000 (207)

6000 (413)

® -423 (-252) 500 (260) 3000 (207) 6000 (413)

TYPICAL LIFTING ARRANGEMENT

LIFTING BRACKETS

ROTATED 60-90°IN THIS VIEW

Loading...

Loading...