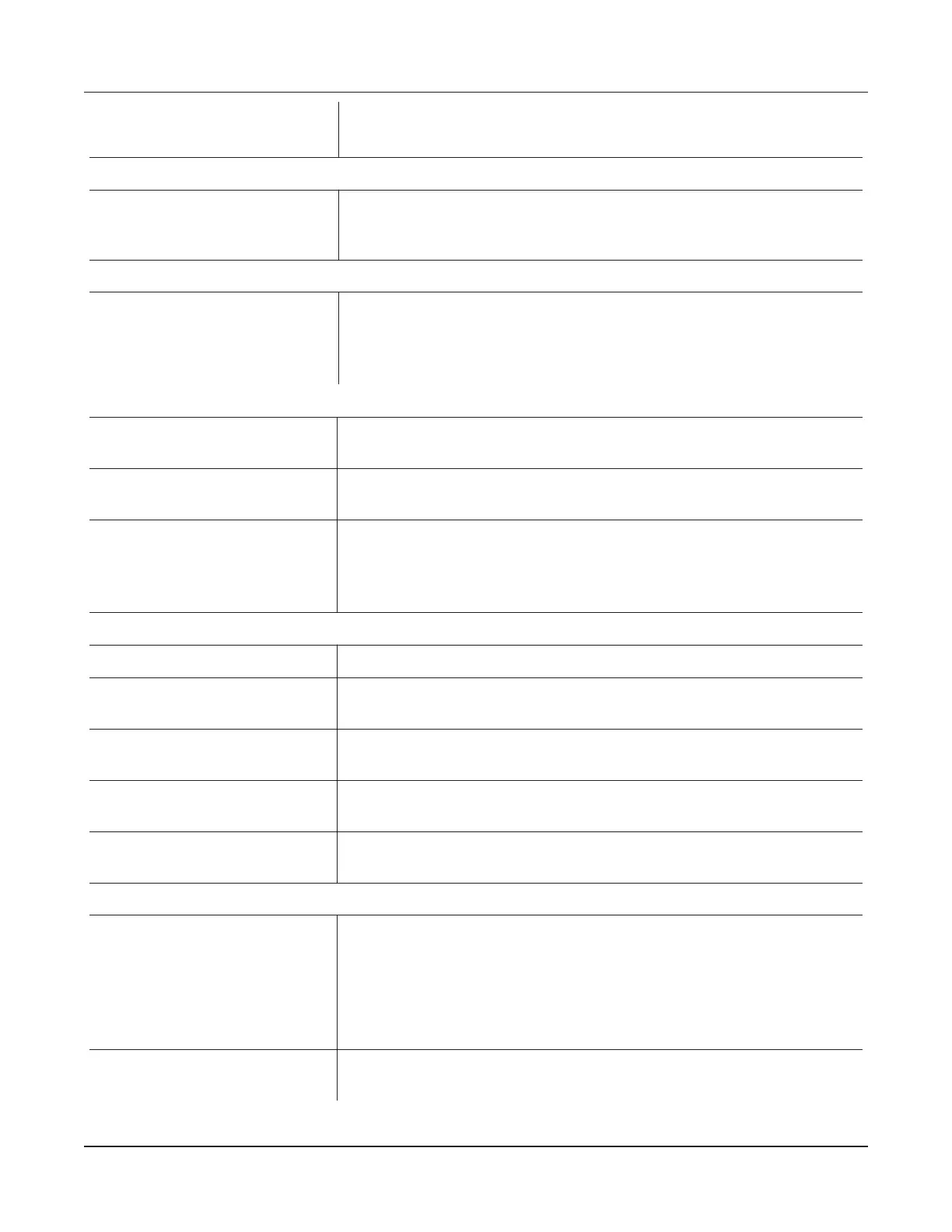

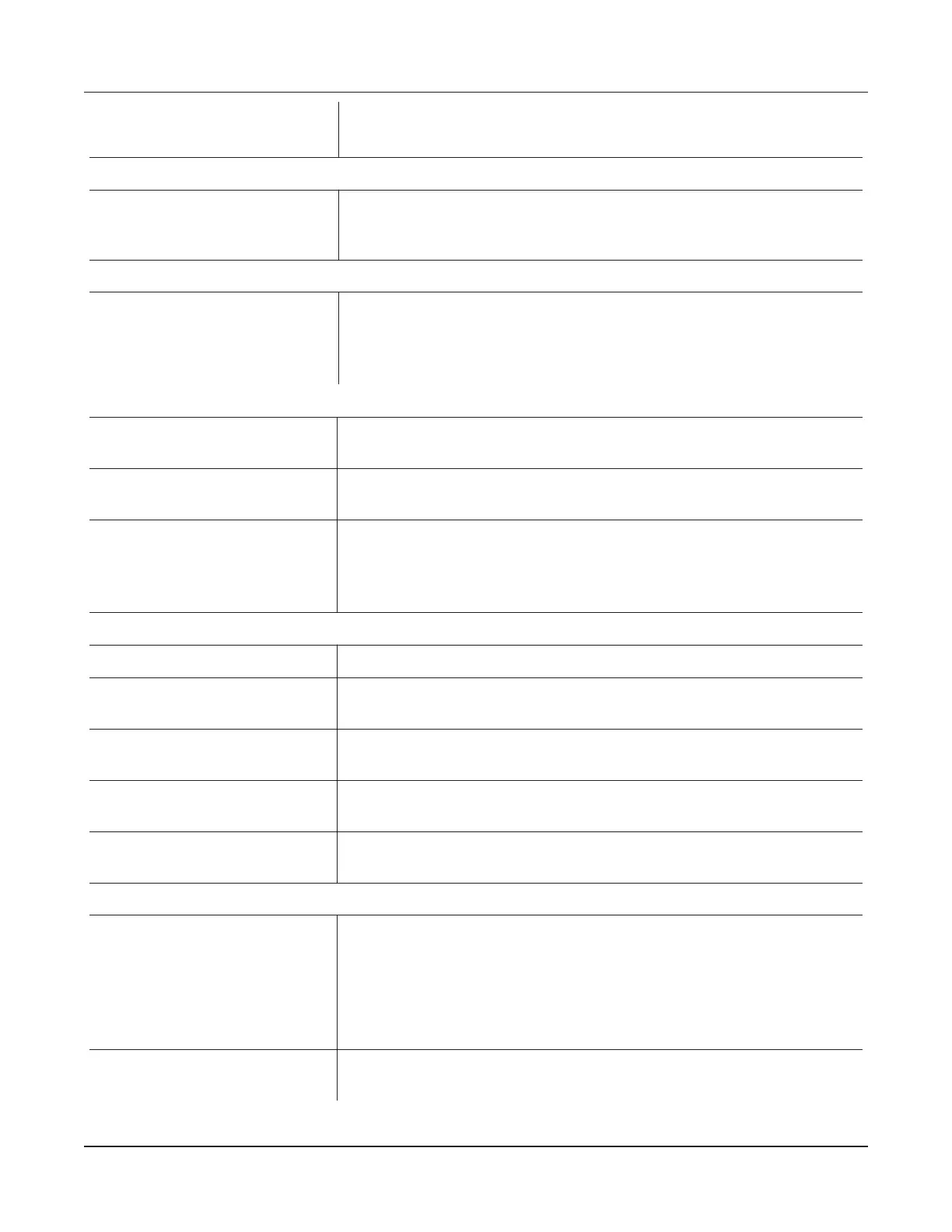

Misaligned end bells 1. Remove intensifier from pump and place on assembly fixture.

2. Loosen tie rods and retorque. Confirm that end bells are aligned correctly.

5. Oil leaking from manifold/shift valve interface

Defective or worn o-ring seals; loose

shift valve mounting screws

Retorque the shift valve mounting screws, using torque values in this manual. If

leak doesn't stop, replace interface o-ring seals between manifold and shift

valve.

6. Oil leaking from shift valve/pilot valve interface

Defective/worn o-rings, loose pilot

valve mounting screws, or incorrect

torque

Retorque pilot valve mounting screws, following the torque values in this man

-

ual. If leak won’t stop, replace interface o-ring seals between pilot valve and

shift valve.

7. Water leaking from end bell weep hole

Worn high-pressure water seal Replace all high-pressure water seals and seal backup rings. Be careful not to

scratch the water cylinder during seal extraction and insertion.

Fractured high-pressure water cylin

-

der at the end bell side

Replace water cylinder and seals. Be careful not to scratch the high-pressure

water cylinder during seal insertion.

Worn high-pressure water plunger 1. Inspect plunger diameter. The diametrical clearance between plunger and

new backup ring must be less than 0.002 inch (0.05 mm). Replace if

scratched, pitted or below tolerance.

2. Replace water seals and seal backup ring.

8. Water leaking from end cap weep hole

Worn HP water seal Replace high-pressure water seal.

Damaged low-pressure water seal

o-rings on the check valve body

Replace water seal o-rings. Do not pinch the o-ring seals when installing check

valve housing.

Fractured high-pressure water cylin

-

der

Replace cylinder and high-pressure seals. After replacement, increase pressure

gradually.

Fractured check valve body Inspect for fractures. Replace check valve body if required. Replace all water

seals.

End cap incorrectly assembled to

high-pressure cylinder

Remove end cap and reassemble. Replace HP water seal (if damaged).

9. Short high-pressure water seal life

Excessive clearance between seal

backup ring and HP water plunger

1. Remove HP water cylinder. Replace all HP water seals (backup ring, seal,

hoop, and o-ring).

2. Examine HP plunger. Replace if diameter is less than specified or if surface

roughness is greater than 4 micro-inch RMS.

Caution: High-pressure seal rings must be replaced whenever high-pres

-

sure seals are replaced.

Scratched HP water plunger Deep pits or scratches in excess of 10 micro-inches will cause premature

high-pressure water seal failure. Replace as necessary.

10 | M-310 © Flow International Corporation

ESL Intensifier

Loading...

Loading...