Copyright Reserved, DONGYANG Corporation 6

4.0 CAUTIONS FOR INSTALLATION

Mounting Positions

• Pipes must be fully filled with liquids. It

is essential that pipes remain fully filled

at all times, otherwise flow rate

indications may be affected and

measurement errors may be caused.

• Avoid Air Bubbles. If air bubbles enter

a measurement pipe, flow rate

indications may be affected and

measurement errors may be caused.

• Avoid all pipe locations where the flow

is pulsating, such as in the outlet side of

piston or diaphragm pumps.

• Avoid locations near equipment

producing electrical interference such as

electric motors, transformers, variable

frequency, etc.

• Install the meter with enough room for

future access for maintenance purposes.

• The mag meter isolating liner, whether

if it is PTFE or Rubber, is not intended

to be used as gasket material. Standard

gaskets (not provided) should be

installed to ensure a proper hydraulic

seal. When installing the gaskets, make

sure they are properly centered to avoid

flow restriction or turbulence. Do not

use graphite or any electrically

conductive sealing compound to hold

the gaskets in place during installation.

This could affect the reading accuracy

of the measuring signal.

Warning: Precaution for direct sunshine and rain when the meter is installed outside.

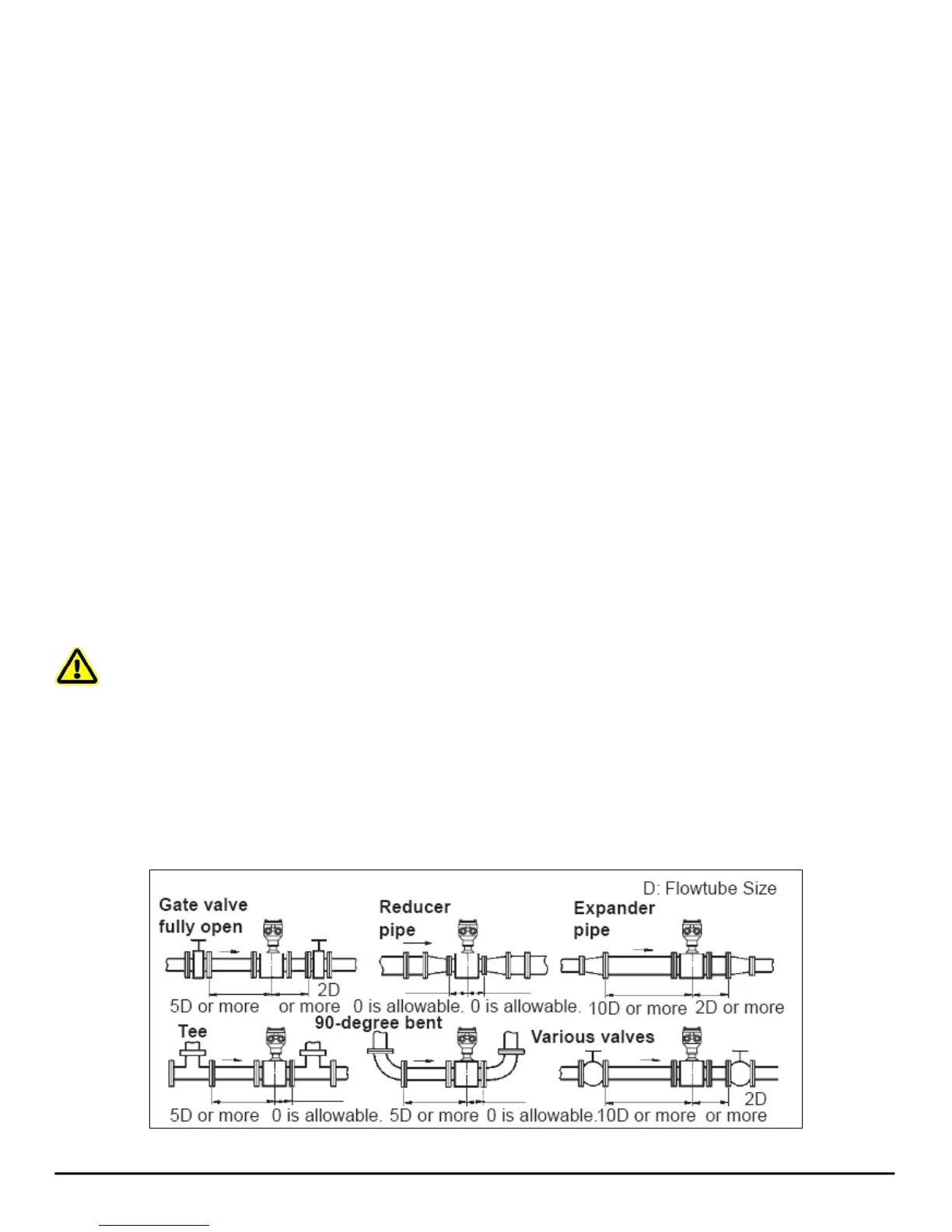

Required Lengths of Straight Runs

For optimum accuracy performance, it is required to provide sufficient inlet and outlet straight

pipe runs. An equivalent to 3 diameters of straight pipe is required on the inlet side, and 2

diameters on the outlet side. There are no special requirements for standard concentric pipe

reducers. See diagram1 for required straight runs when there is altering device.

Diagram 1. Required straight runs

Loading...

Loading...