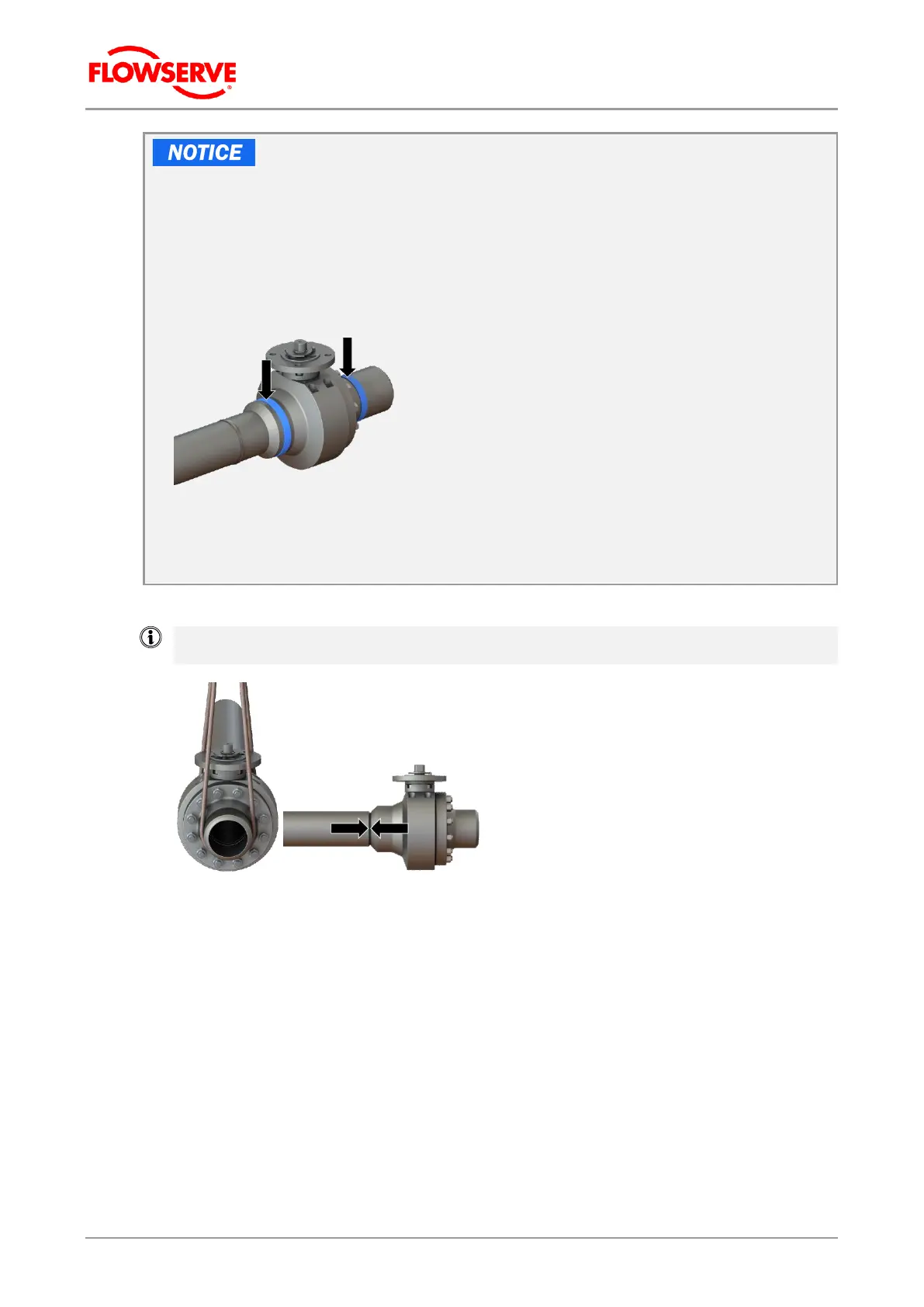

Risk of property damage due to excessive heat!

In the case of short welding ends, excessive heat from welding works may cause damage

to the soft seal.

If possible, put a wet towel over the Argus Ball Valve.

Monitor the temperature of the valve body in the seat area by using the temperature-

sensing strips (shown here in blue) during welding.

The maximum permitted temperature is: 100 °C

(position of the temperature-sensing strips)

Continuously monitor the temperature strip during welding.

In case of a reaction (color change), interrupt the welding.

Let the valve body cool down.

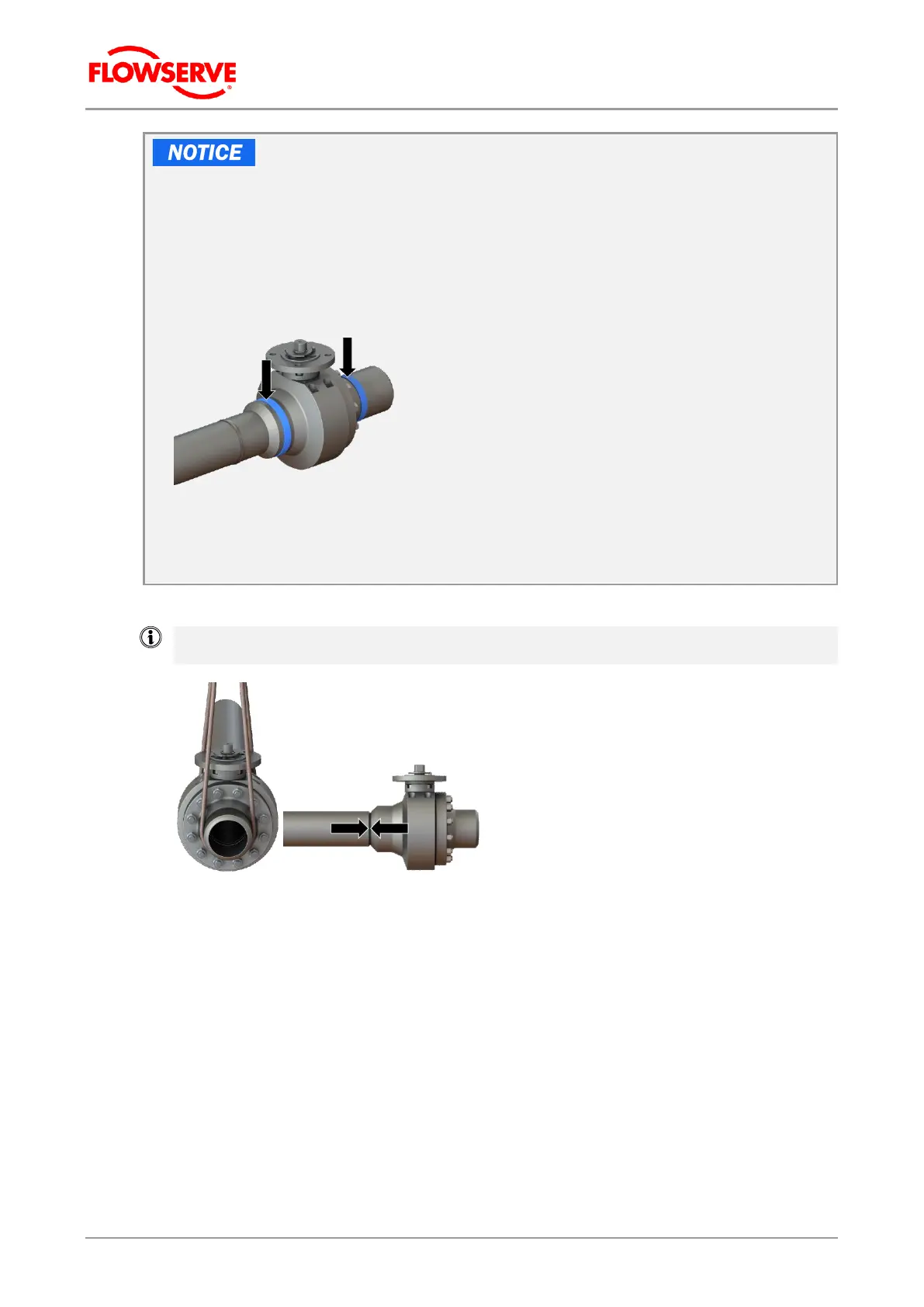

5. Weld the Argus Ball Valve to the first welding end.

Ensure correct placement and correct alignment of the Argus Ball Valve with the piping

connection.

Loading...

Loading...