Argus Ball Valve EK, FK and HK Operating Manual – BA1000 EN

12 Transportation

Page 58 of 67

12.2 Transporting the Argus Ball Valve

Ensure that the following conditions apply:

The Argus Ball Valve

Is disconnected from the piping

Is free from any fluid residues and substances (observe national regulations on

disposal of hazardous waste)

Is in the open position (as supplied)

Is free from any dirt

Is dry

1. Attach protective factory fitted caps to the Argus Ball Valve (including Volatile

Corrosion Inhibitor paper).

Protective factory fitted caps prevent the penetration of dirt and foreign particles into

the interior of the Argus Ball Valve. The cap also protects the flange sealing surface, the

welding end, and the connecting thread from corrosion and other damage.

2. Use protective packaging materials to protect the Argus Ball Valve from damage

during transport (e.g., packaging cover).

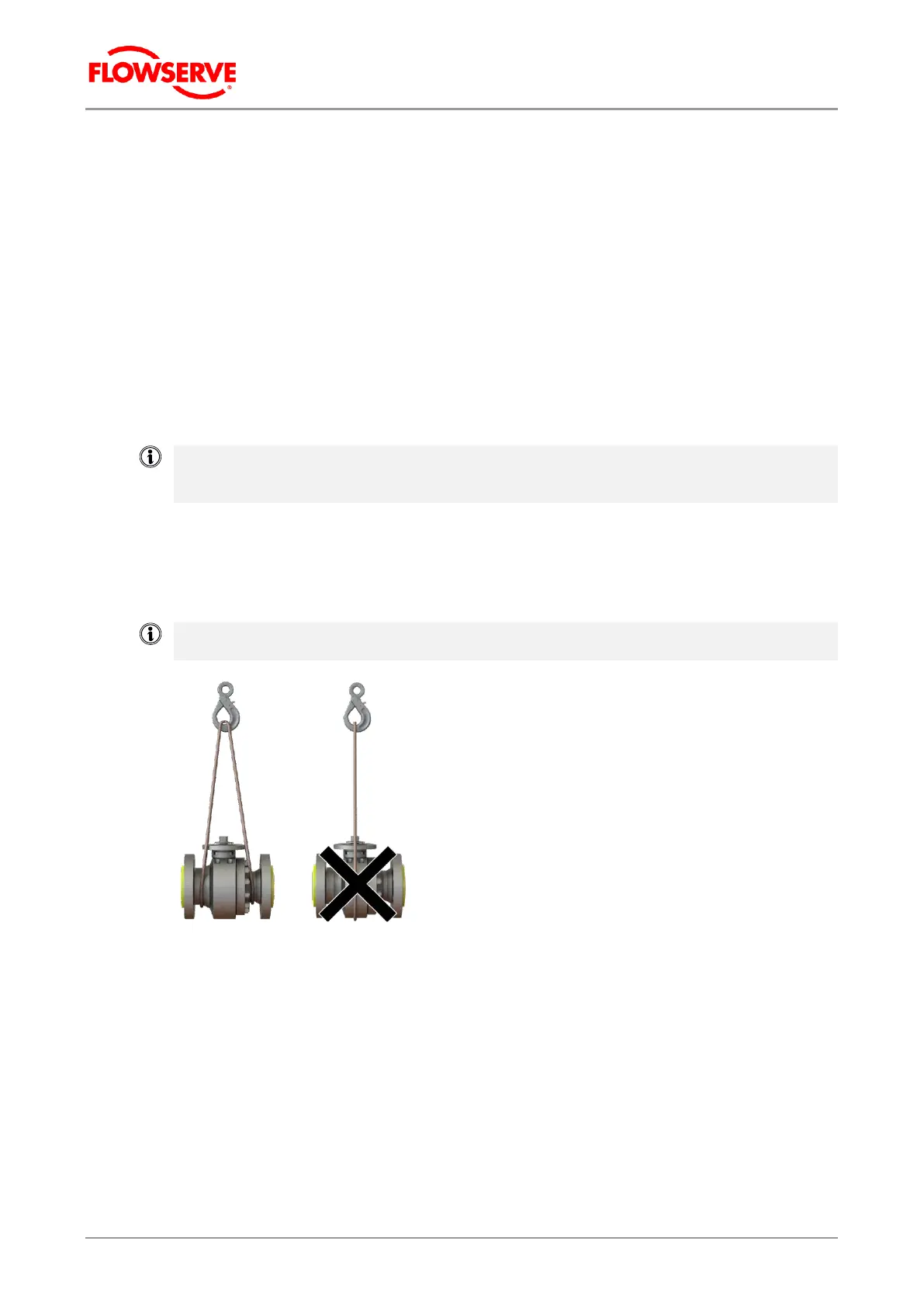

3. Position appropriate lifting straps around the Argus Ball Valve body or attach

them to lifting eyelets, if they are present.

Note that when lifting straps around the Argus Ball Valve are used the center of gravity

can be higher than the attachment point.

4. Ensure that the Argus Ball Valve cannot twist or tip over.

5. Put the lifting straps into the load hook of an appropriate hoist or swing crane.

6. Lift the Argus Ball Valve to the desired location and set it down safely.

7. Remove the lifting straps from the Argus Ball Valve.

Preparation of the Argus Ball Valve for transport and its transport are now complete.

Loading...

Loading...