FlowAct Diaphragm Linear Actuator FCD VLENIMFACTA4 10/16

9

flowserve.com

WARNING

Diaphragm linear actuators are pressure vessels.

Improper opening of the actuator can result in bodily injury.

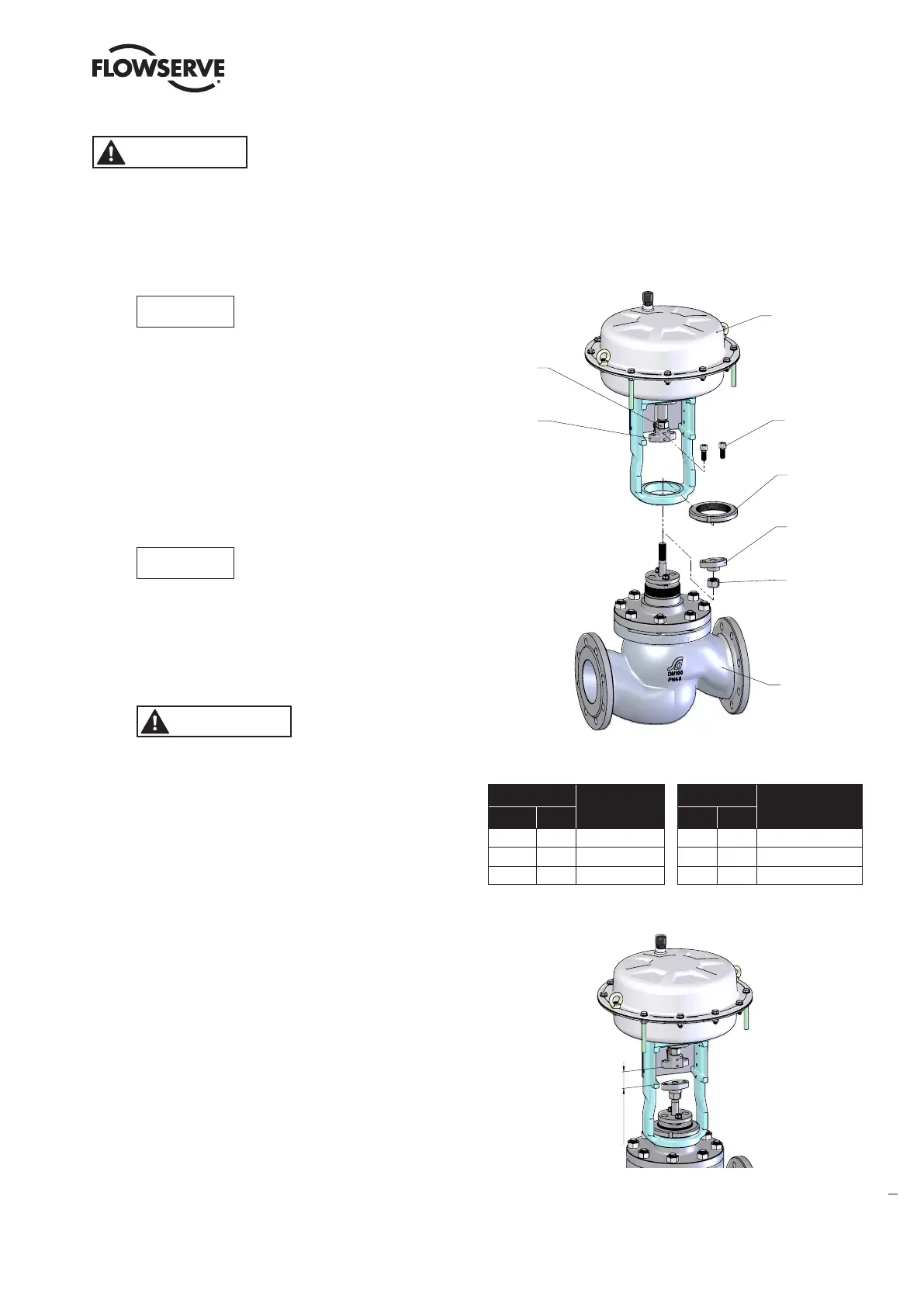

Actuator assembly procedure

1. Fix the valve on the assembly table.

NOTICE

The orientation of the valve must be

in accordance with the appropriate

mounting position !

2. Lubricate all threads with a suitable, approved lubri-

cant (see Section 16).

3. Mount the actuator / yoke and yoke lock nut (76) onto

the valve bonnet.

4. Finger tighten and fix the yoke lock nut; turn clockwise

(see Section 15).

NOTICE

The legs of the yoke should be paral-

lel to the flow direction !

5. If the fail safe position at air failure moves the stem

into closing position then must the actuator connected

with the air supply to move the stem into the open

(retracted) position (in most cases).

WARNING

Due to risk of crushing

hazard, do not work be-

tween the yoke legs while the valve is in operation.

6. Mount the lock nut (113) and lower coupling (345)

onto the valve stem.

7. Justify the plug against the seat.

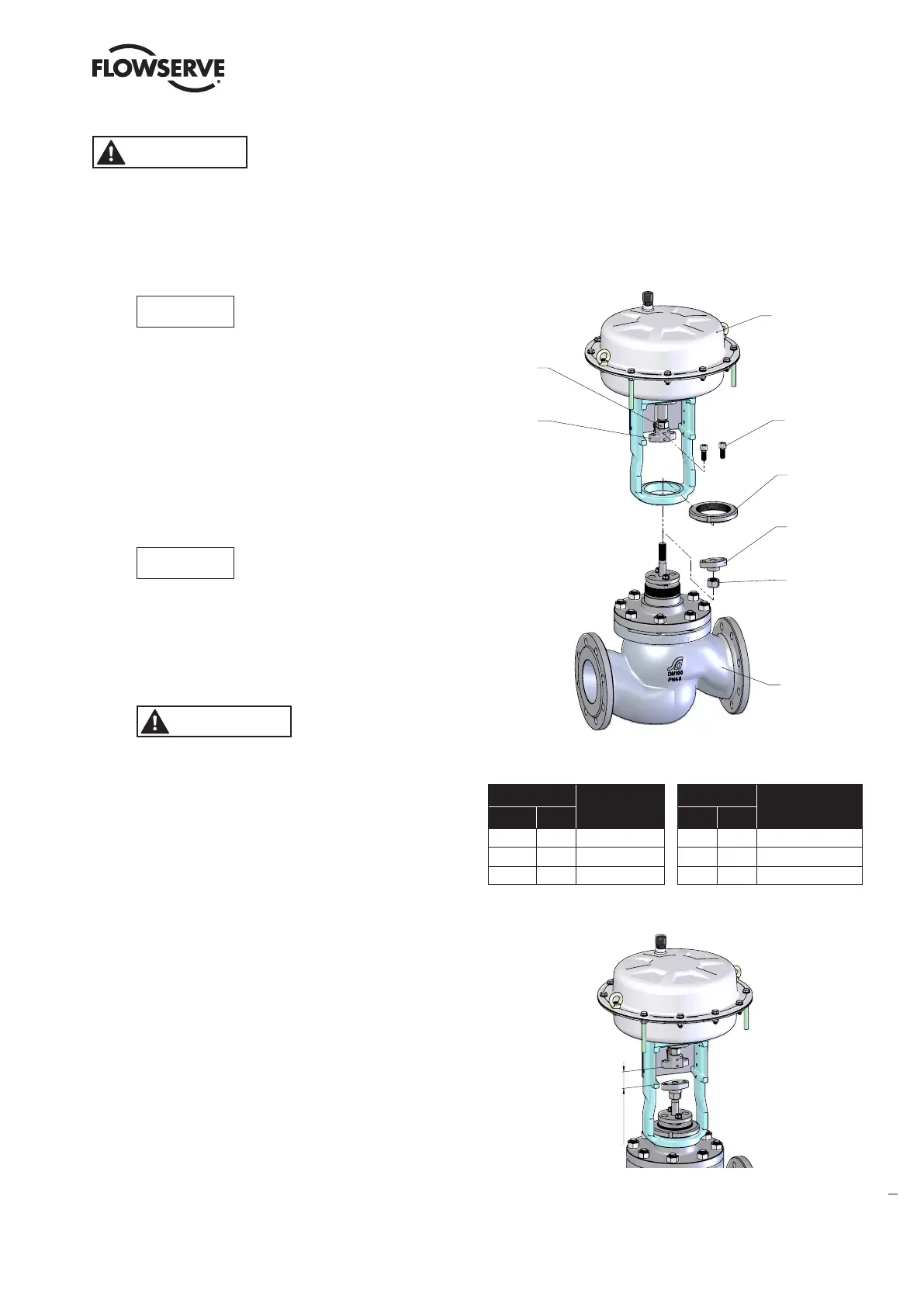

8. Adjust the distance between the lower coupling (345)

ant the upper coupling (249) with the aid of an adapter

in stroke height (Figure 7).

9. Disconnect the air supply so that the actuator moves

to the close position.

10. Mount the cap screws (240).

11. Lock the lock nut (113). Secure the upper coupling

(249) against turn unwanted with a wrench.

12. Adjust the stroke indicator scale so that the zero mark

is in conjunction with the stroke indicator.

13. Perform three full strokes and check if the stroke indi-

cator scale correspond with the end positions.

Actuator

240

76

345

113

Valve

249

344

Figure 6: Yoke assembly drawing

Item

Part

Item

Part

WW

EU

WW EU

76 5.10 Yoke lock nut 249 5.3 Upper coupling

113 5.2 Lock nut 344 5.4 Lock nut

240 5.5 Cap screw 345 5.1 Lower coupling

Table 4: Coupling parts identification

Stroke

Figure 7: Stroke adjusting

14. The valve is ready for the mounting of the accessories.

Loading...

Loading...