1630-2/1630-2 FC

Calibration Manual

8

Performance Verification

Before you do the verification:

1. Make sure that you have the required equipment. See Table 4.

2. Make sure the Product battery is good and replace it if necessary.

3. Warm up the Calibrator as necessary. Refer to its specifications.

4. Let the temperature of the unit under test (UUT) become stable to room temperature.

5. Use the loop of wire to apply signals to the 1630-2. The loop should have a straight section that goes through

the jaws. A 2-foot section of 16-gauge copper wire makes a good, stable loop.

Note

The loop has resistance that will have to be included in the applied resistance. The

2-foot section of 16-gauge copper wire adds about 0.01 Ω. Make a 4-wire

measurement of the loop to include in the applied resistance.

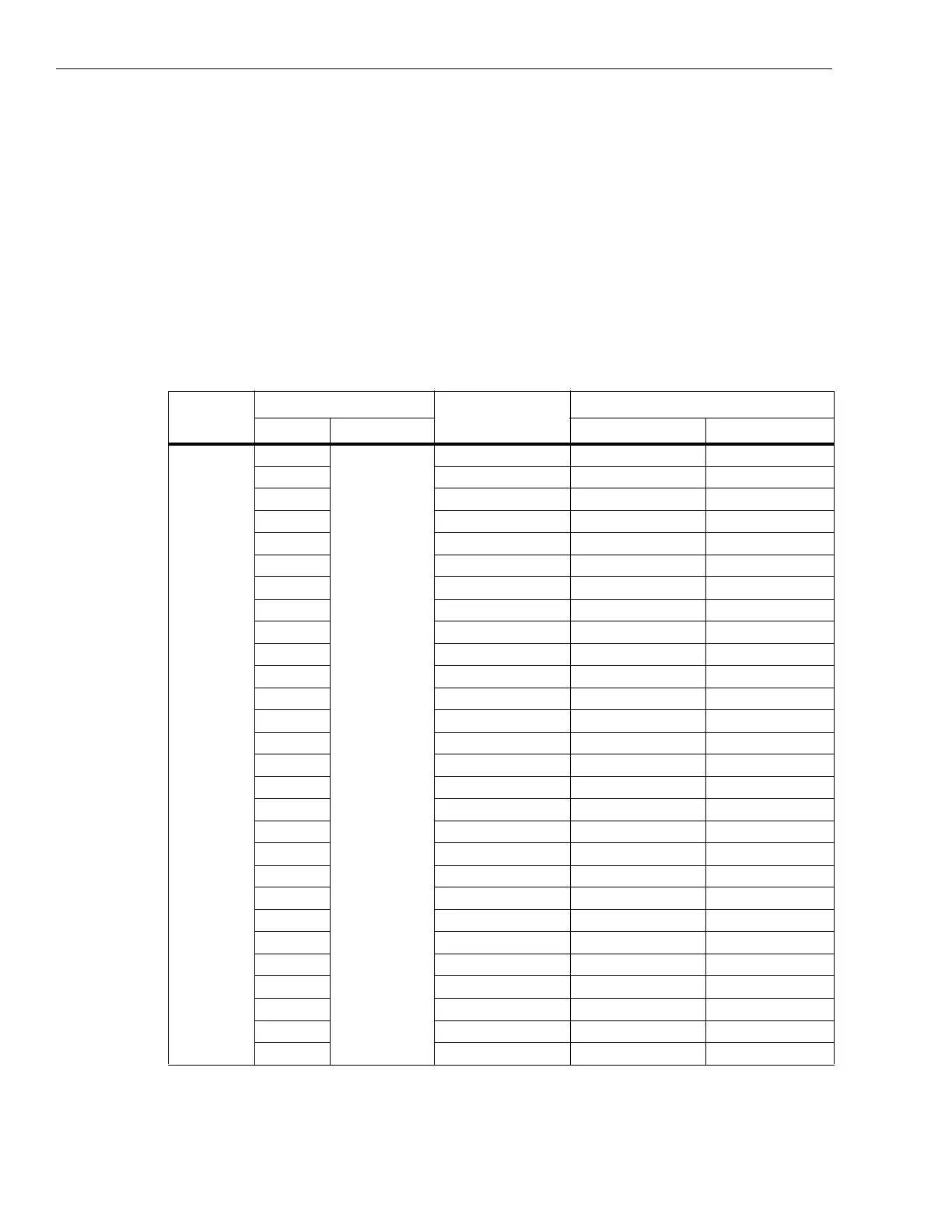

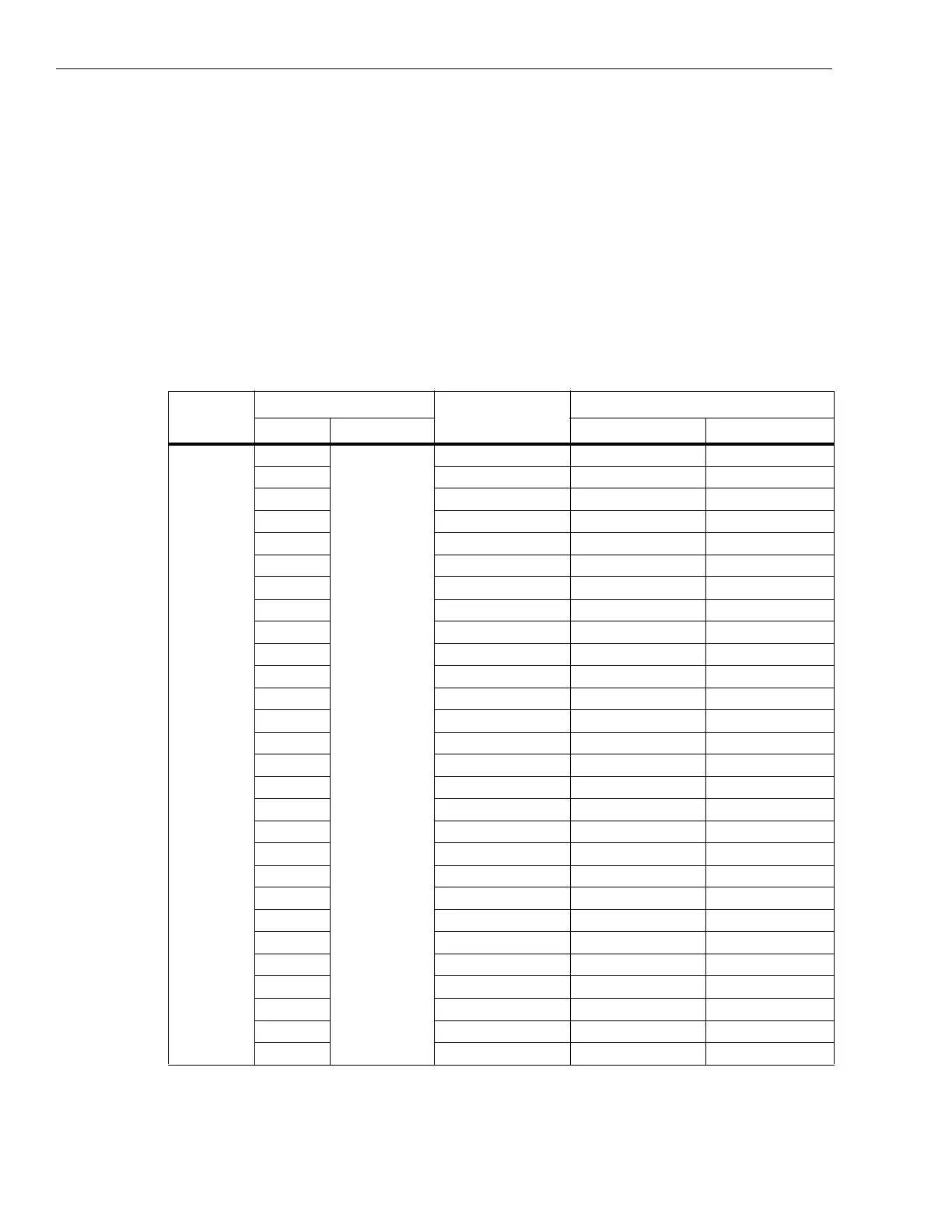

Table 4. Performance Test Points for Resistance

Function

Test Point

Applied Resistance

Display Reading

Value Unit Lower Limit Upper Limit

OHM

0.080

Ω

0.080 – Loop Ω 0.059 0.101

0.120 0.120 – Loop Ω 0.098 0.142

0.230 0.230 – Loop Ω 0.207 0.253

0.280 0.280 – Loop Ω 0.226 0.334

0.450 0.450 – Loop Ω 0.393 0.507

0.550 0.550 – Loop Ω 0.492 0.608

0.900 0.900 – Loop Ω 0.837 0.964

1.100 1.100 – Loop Ω 0.984 1.217

1.800 1.800 – Loop Ω 1.673 1.927

2.300 2.300 – Loop Ω 2.166 2.435

4.500 4.500 – Loop Ω 4.333 4.668

5.500 5.500 – Loop Ω 5.318 5.683

8.000 8.000 – Loop Ω 7.780 8.220

11.00 11.00 – Loop Ω 10.54 11.47

18.00 18.00 – Loop Ω 17.43 18.57

23.00 23.00 – Loop Ω 22.36 23.65

40.00 40.00 – Loop Ω 39.10 40.90

60.00 60.00 58.60 61.40

90.00 90.00 88.15 91.85

120.0 120.0 115.4 124.6

180.0 180.0 173.6 186.4

220.0 220.0 204.0 236.0

360.0 360.0 337.0 383.0

450 450 395 505

550 550 485 615

700 700 560 840

900 900 720 1080

1300 1300 1040 1560

Loading...

Loading...