SECTION

H OPTIONS

AND ACCESSORIES

(d) Secure the other stop lug.

(e)

Move the RIGHT-HAND

rim outwards using the above

procedure with

low reverse gear selected and the

left-hand brake pedal held down.

(f) Using the

special spanner provided tighten the locking

nuts

(1).

On the

Ford 4000 and 5000

tighten only the marked nuts

with the wheel in the

original position as (a).

Tighten the nuts gradually,

ensuring that the

exposed

thread outside each nut is the

same.

To decrease the

width of the

rear

track

within one of the two ranges:

Use the

above procedure selecting

directly opposite gears to those stated

in

stages (c) and (e).

To change from

one width range to

the other:

FORD 2000

AND 3000

Interchange the left-hand and right-hand

wheel assemblies ensuring

that the

'Vee'

of the tread is pointing in the

forward travel direction.

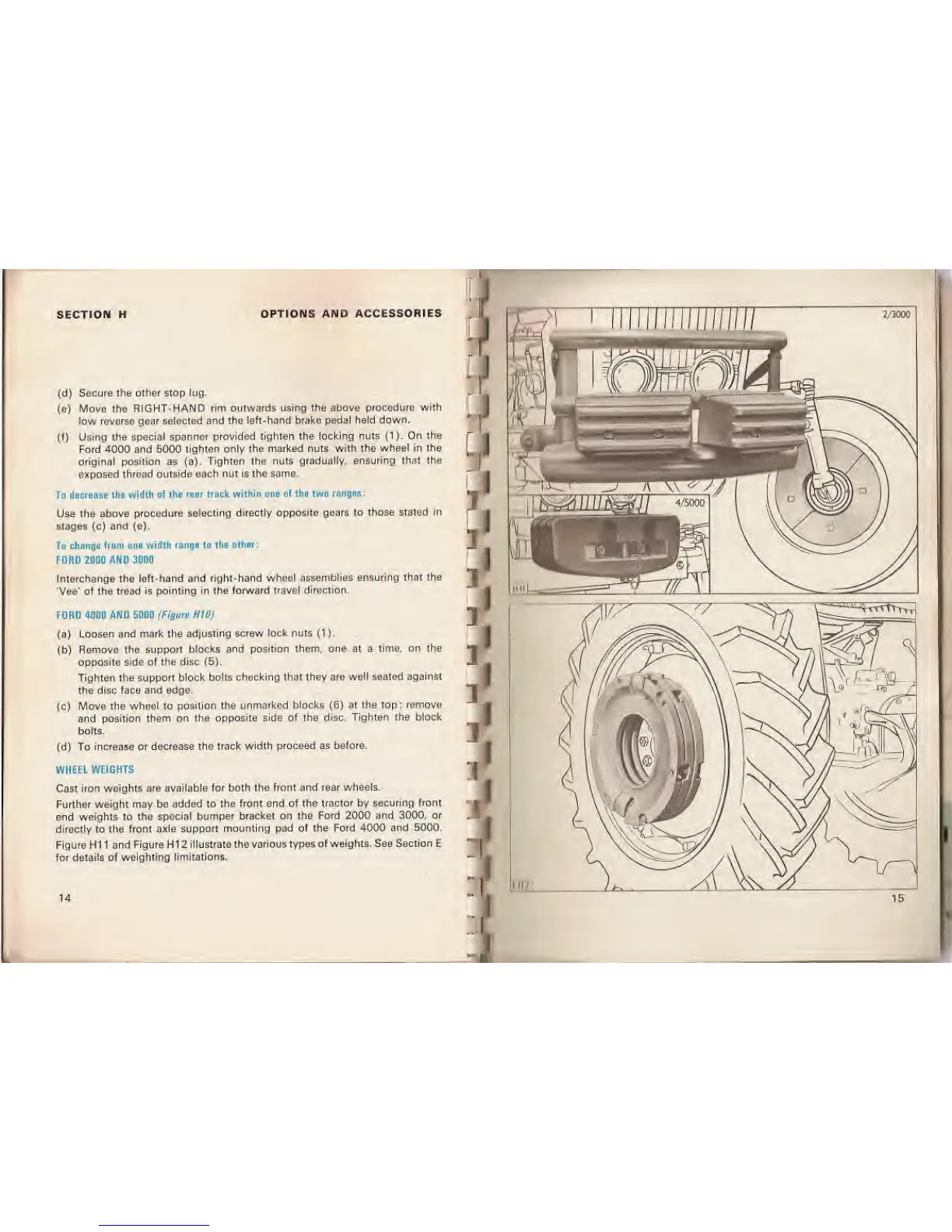

F0R0 4000 AND 5000

(Figure H1Q)

(a) Loosen and mark the

adjusting screw lock nuts

{1

).

(b)

Remove the support

blocks and position them, one at a

time, on the

opposite side of the disc

(5).

Tighten the support

block bolts checking that they are

well seated against

the disc face and edge.

(c)

Move the wheel to position the

unmarked blocks

(6)

at the top;

remove

and position

them on the

opposite

side

of the disc. Tighten the block

bolts.

(d)

To increase or decrease the

track width proceed as

before.

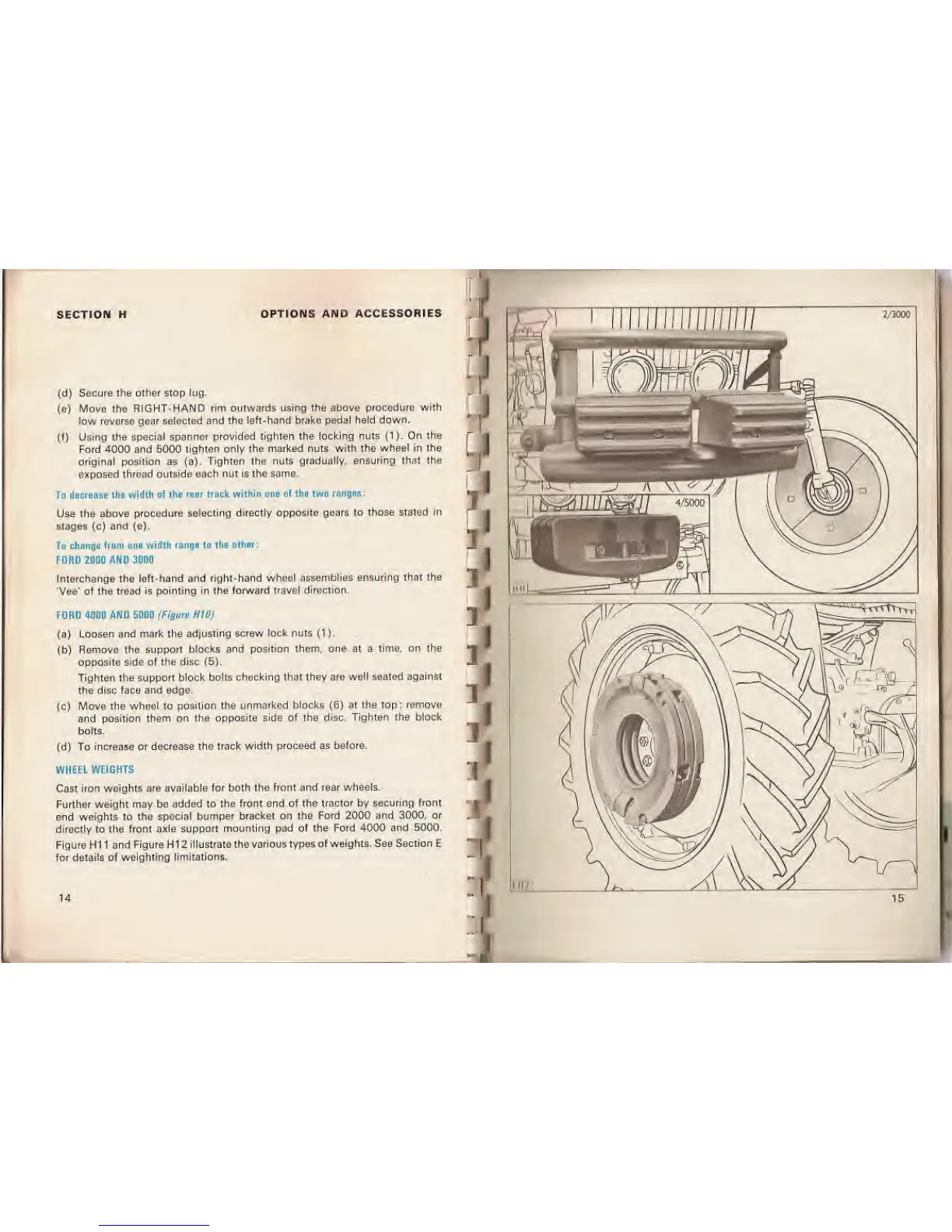

WHEEL

WEIGHTS

Cast iron

weights are available

for both the front and rear wheels.

Further weight

may

be

added to the front end

of the tractor by securing

front

end weights to the special

bumper bracket on the

Ford 2000 and 3000, or

directly to the front axle

support mounting pad of the Ford 4000

and 5000.

Figure H1 1

and Figure H1 2 illustrate the

various types of weights. See Section E

for details of weighting

limitations.

14

Loading...

Loading...