37

Maintenance

Annual Maintenance Checks:

In addition to the Monthly Maintenance, the items detailed below should be

checked and adjusted as necessary.

• Check the hydraulic reservoir oil level and top up if required with hydraulic

oil ISO 32.

• Check the tailboard lower latch mechanism and adjust if necessary.

• Check all electrical cables and ensure that no chaffing has occurred.

• Check the Tipper subframe to chassis fixings.

• Check the rear corner pillar fixings.

• Check the headboard securing fixings.

• Check the fender mounting bracket fixings.

• Inspect the Tipper deck / subframe and associated components for

damage. Replace or repair locally to maintain Tipper functionality and

roadworthiness.

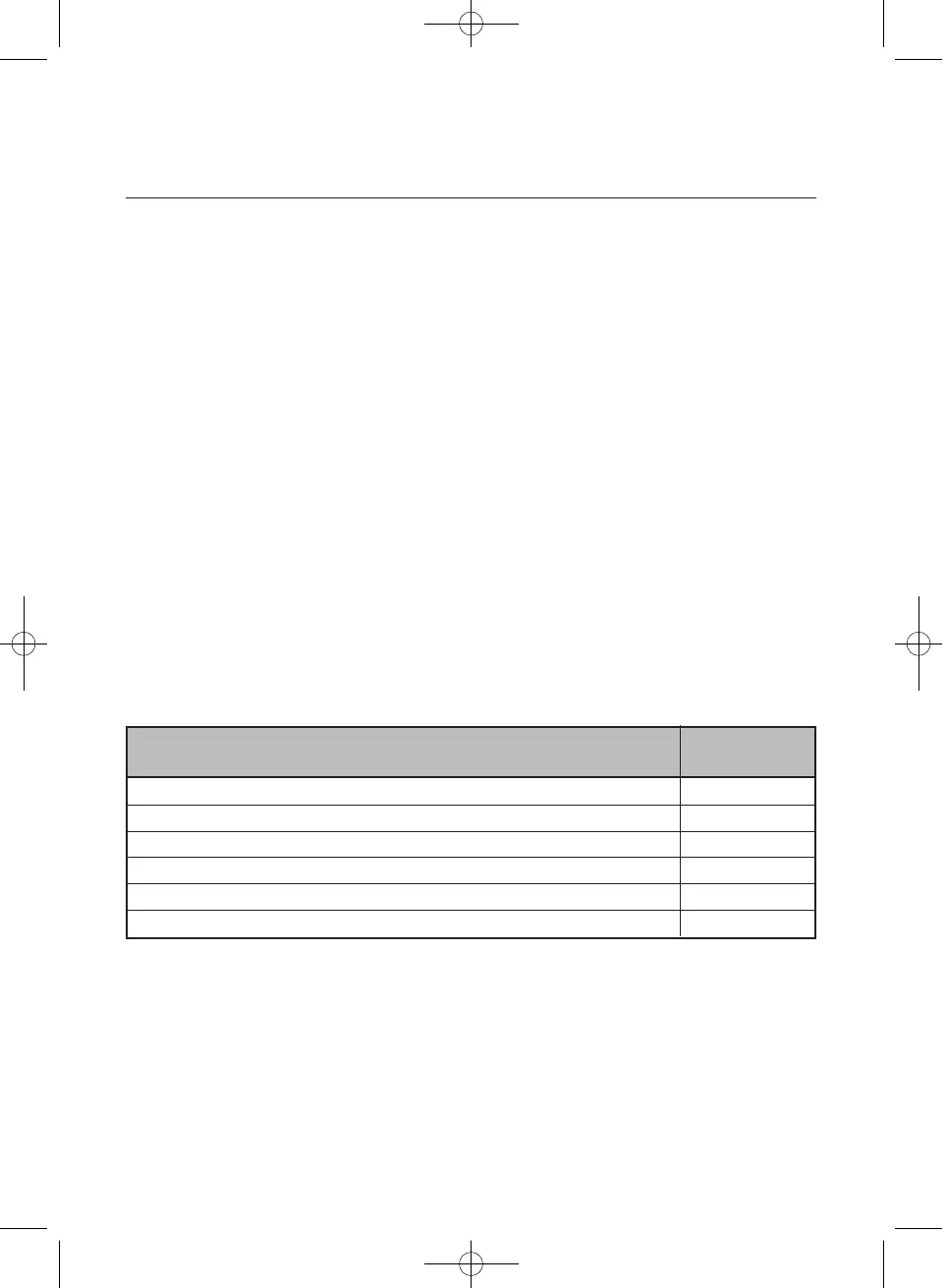

Specified Torque Figures

Description

Torque Value

(Nm)

Tipper subframe to vehicle chassis fixings. 50

Rear corner pillar mounting fixings. 90

Headboard securing fixings. 25

Rear bolster fixings

(Optional part).25

Fender mounting bracket fixings. 25

Side marker lamp mounting bracket fixings

(Double Cab only) 25

Loading...

Loading...