25

WARNING: An incorrectly mounted brake hose or a hose that is in contact with moving

parts of the bicycle can compromise the braking action and cause serious accidents.

CAUTION: After the brake has been installed, make sure the handle bar turns freely; if

the brake hose gets in the way, make the required adjustments so that it does not or

contact the manufacturer.

1.3 Installing the caliper

ATTENTION: neverinstalltheFORMULASRLcalipersusingadaptersorsupportsmade

by other manufacturers. Failure to heed this precaution will void the warranty. Use only

partsmanufacturedbyFORMULASRLmountedonforksorframesprovidedtoavoidac-

cidents and serious injury.

CAUTION: Onlycorrectmountingofthesystemandit’svarioussupportelementswill

ensurethesafetyofthecyclistandtheexceptionalperformanceofFORMULASRLdisc

brakes.

Toadaptframesorforkstothevariousdiametersofbrakerotorsavailable,FORMULASRLsup-

plies different adapters which can be mounted between the fork or frame and the brake caliper.

Fitthecalipertothefork,proceedingasfollows:

INTERNATIONAL STANDARD MOUNT OR SIMILAR

WARNING! DO NOT DISASSEMBLE OR ATTEMPT MODIFY, THIS NEW

FORMULA SRL PRODUCT!

Serviceonthisproductmustbeperformedonlybyqualifiedprofessionalme-

chanics who are familar with and understand the technical details of how this

product works.

If you choose to ignore this important safety warning, you are doing so at your

ownriskandatnolegalliabilitytoFORMULASRLoritsdistributors.

CAUTION: Fordiscinstallation,useadynamometric(Torque)wrenchsuitableforthe

given tightening torque.

CAUTION: Whenremovingthescrews,alwaysmakesurethatmediumstrengthLoctite®

is applied when reassembling, and that the correct torque wrench settings are used.

R1-RX-T1-R1S-R0–R1RACINGcanbeused

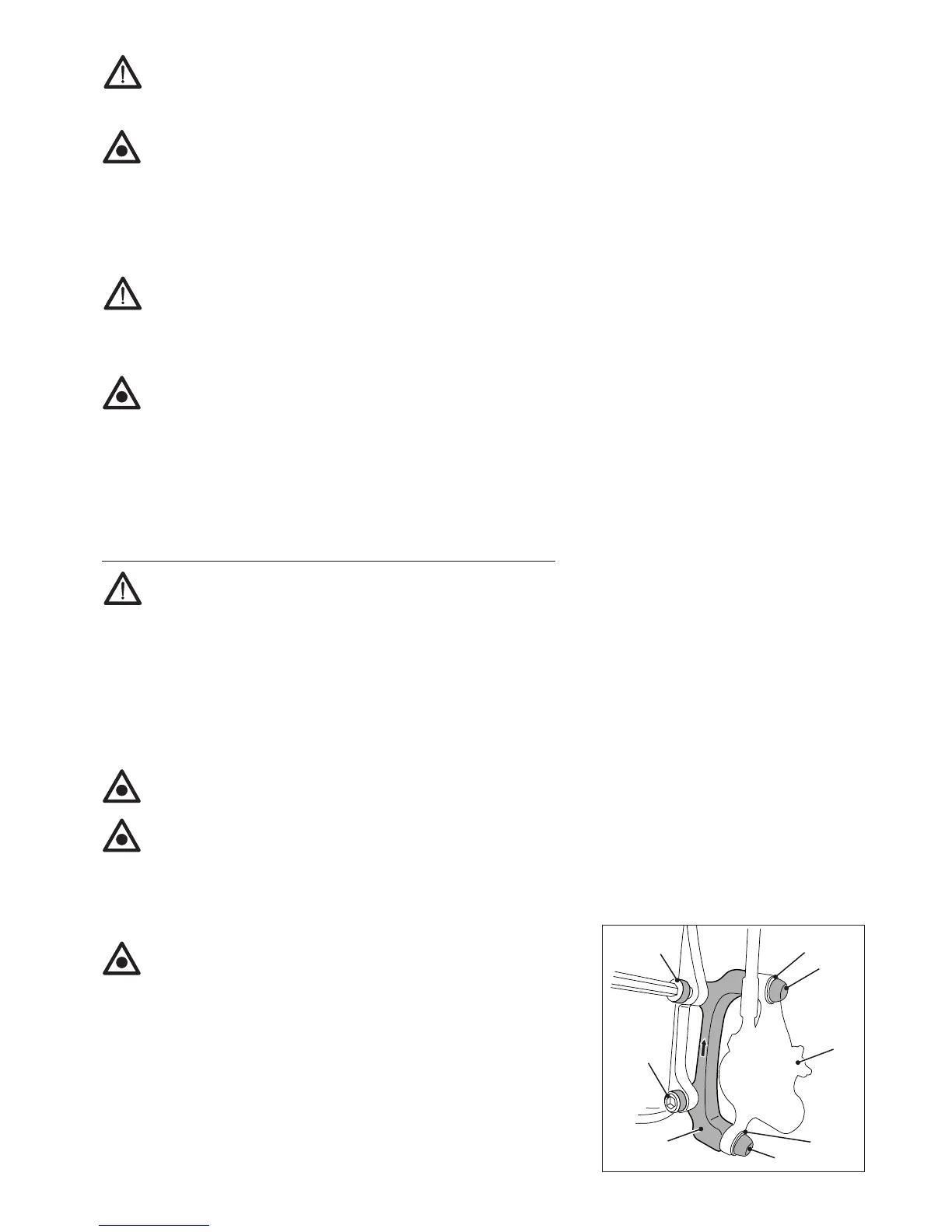

CAUTION: Make sure the washers 9 and thread-

blocker are present on screws 9a and 8 before at-

tempting to start assembly. Apply medium-strength

threadblocker(ifnotpresent).

- Place the adapater 6ontheframe(orfork)withthearrow

facing the direction in which the wheel turns.

- Insert the screws and washers 9a tightening them with

a 5mm hex. socket wrench to a torque setting of 9

Nm±5%.

9

9A

9A

8

9

8

7

6

Loading...

Loading...