9. Inspect the lubricant for discoloration. Under nor-

mal conditions, the lubricant will darken; a white

or milky appearance indicates water contamina-

tion. If the lubricant is discolored, service the

wheel end. See the 108SD and 114SD Work-

shop Manual and manufacturer literature for pro-

cedures.

IMPORTANT: Do not mix different types of lubri-

cants.

10. Inspect the lubricant for the presence of foreign

matter. Use a magnet to detect any metallic ma-

terials present in the lubricant. If the lubricant is

contaminated, service the hub. See the 108SD

and 114SD Workshop Manual and manufacturer

literature for procedures.

11. Rotate the hub and check for free, smooth, and

quiet rotation. If rotation is hampered or rough, or

any unusual noise is heard, service the hub im-

mediately. See the 108SD and 114SD Workshop

Manual and manufacturer literature for proce-

dures.

WARNING

Correct wheel-bearing end play is crucial to the

safe and sound operation of the vehicle. If the end

play is not correct, the wheel bearings could fail

and cause the loss of the wheel and hub assem-

bly and result in an accident causing property

damage, serious injury, or death. Use a dial indica-

tor to measure the end play.

IMPORTANT: Do not measure the wheel bear-

ing end play with the wheel mounted on the

hub; you cannot accurately measure or adjust

bearing end play with the wheel mounted on the

hub. Also, ensure that the brakes are not ap-

plied so that that drum and hub can move freely.

12. Using a dial indicator, measure the end play as

follows.

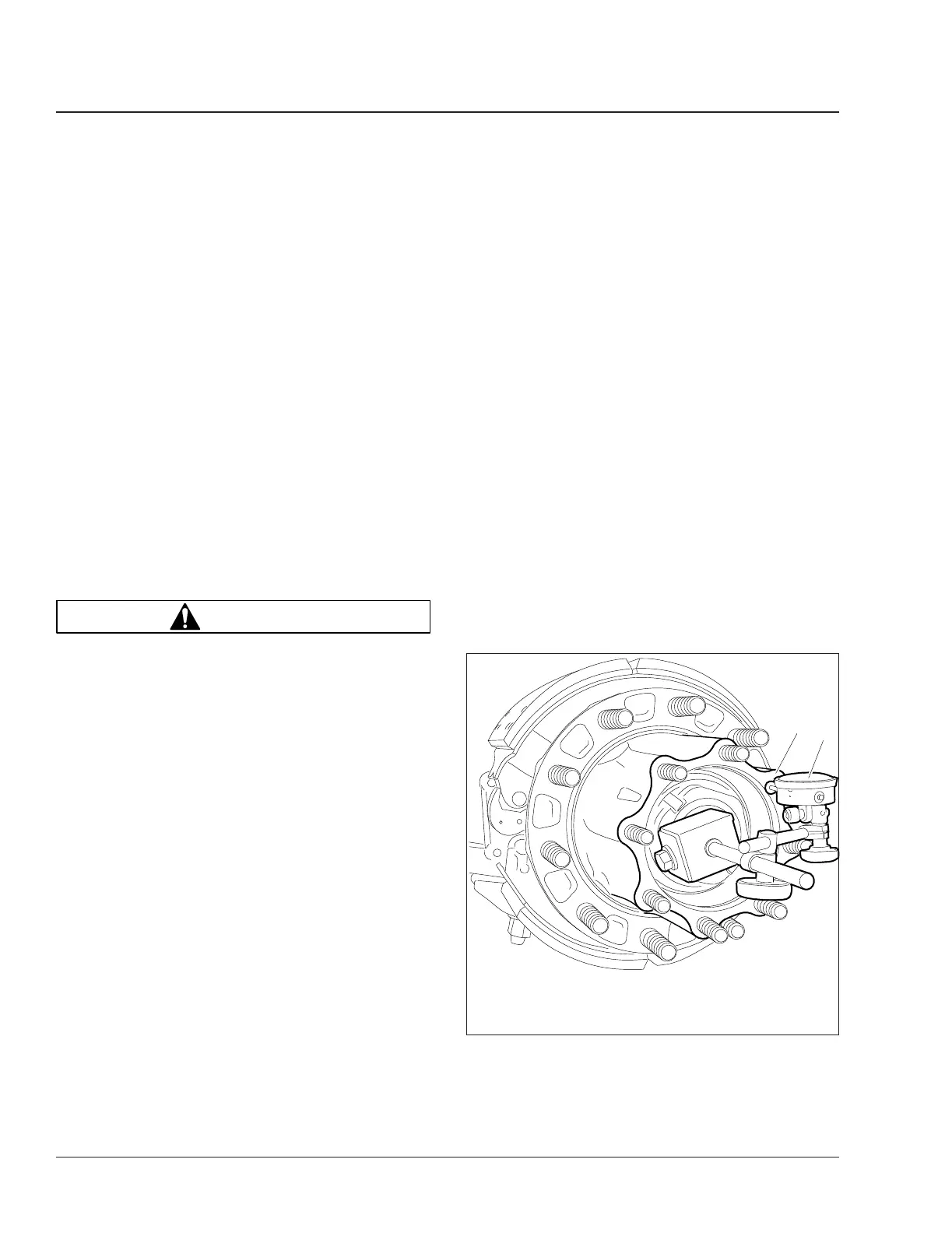

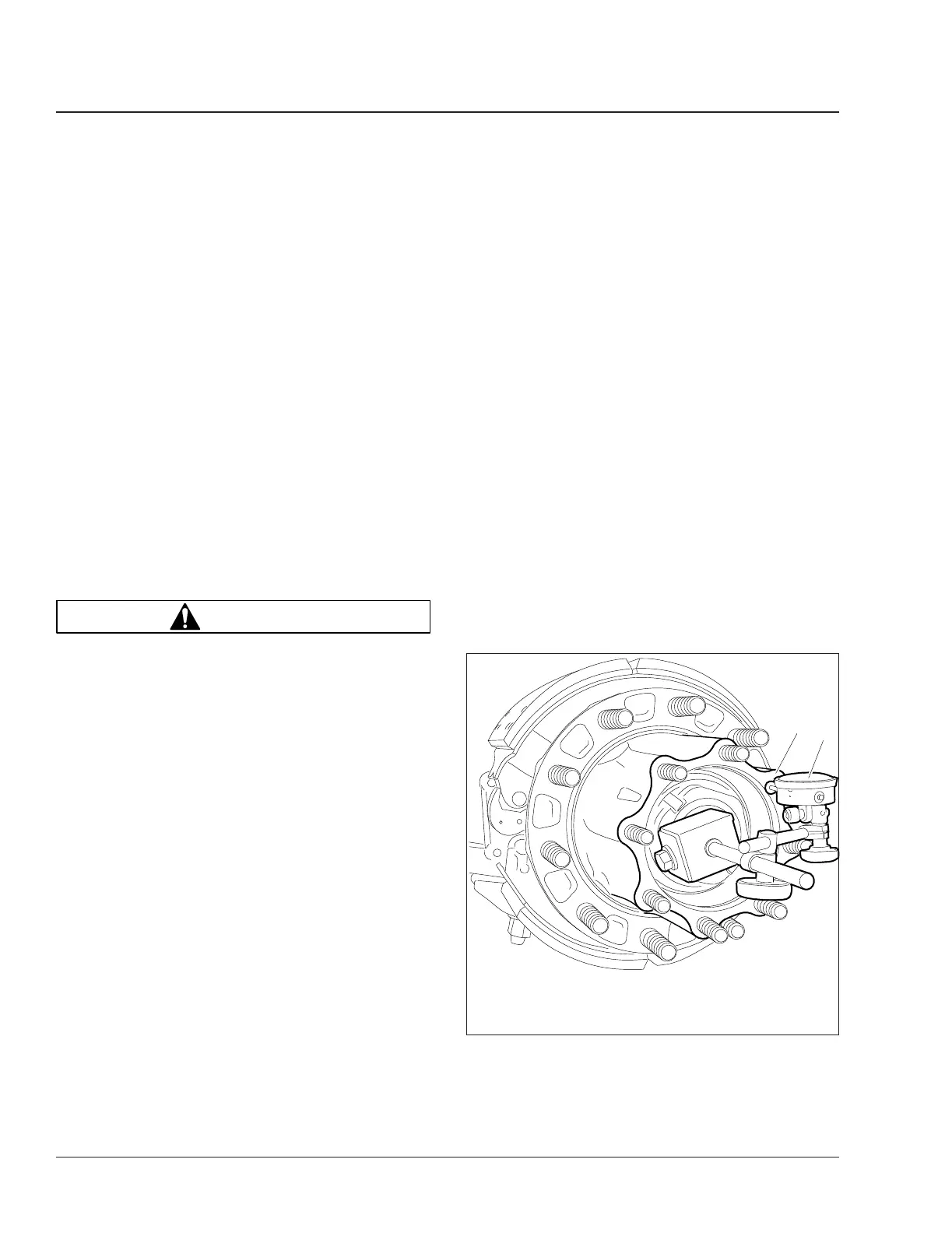

12.1 Attach the magnetic base of a dial indica-

tor to the spindle, and place the measur-

ing end of the indicator squarely against

the flange as shown in

Fig. 7.

IMPORTANT: Maintain continual pressure on

the hub until you have taken both the in-

board and outboard measurements. If you

release the hub, an accurate measurement

is not possible.

12.2 To seat the bearings, grip the hub at the

three o’clock and nine o’clock positions,

and push inward while oscillating it ap-

proximately 45 degrees. Maintain pres-

sure on the hub, note the inboard mea-

surement, and then pull the hub outward

while oscillating it as before. Maintain

pressure on the hub, and note the out-

board measurement.

The end play is the difference between

the two measurements. The end play limit

for PreSet hubs is 0.006 inch (0.15 mm);

for non-PreSet hubs the acceptable range

is 0.001 to 0.005 inch (0.03 to 0.13 mm)

inclusive.

If the end play does not exceed the limit

and no other problems were found in the

previous steps, no additional service is

necessary. If the end play exceeds the

limit, service the hub. See the 108SD and

114SD Workshop Manual and manufac-

turer literature for procedures.

07/05/2011 f350538

1

2

1. Dial Indicator (with magnetic base)

2. Axle Shaft Mounting Flange

Fig. 7, Dial Indicator Setup

Rear Axle35

108SD and 114SD Maintenance Manual, November 201635/8

Loading...

Loading...