move the top plate and inspect the bracket lin-

ers. Replace liners that are broken or less than

0.125 inch (3 mm) thick at the top of the liners.

For the liner replacement procedure, see the

Fontaine website,

www.fifthwheel.com.

6. Check the jaw and stationary jaw for mushroom-

ing, and check that the serrations at the jaw and

wedge are in good condition.

7. Test the secondary safety lock latch for ease of

operation.

8. Check for loose nuts or bolts on the fifth wheel

and the mounting. Set a torque wrench to the

maximum torque value for the bolt being

checked, and confirm that the torque is to speci-

fication. Do not loosen the bolt to check the

torque. See

Group 00 for bolt torque specifica-

tions.

9. Check all springs to see if they are securely fas-

tened, and are not deformed.

WARNING

Do not disassemble the fifth wheel to inspect the

springs. The springs are under extreme pressure,

and could cause serious injury.

10. Check the wedge adjustment.

10.1 Close the fifth wheel on a standard 2-inch

(50-mm) kingpin or similar 2-inch (50-mm)

diameter shaft so that it locks.

10.2 Push on the wedge stop rod with hand

pressure. It should move in 1/4 inch (6

mm) and spring back out on release.

If the free travel is not 1/4 inch (6 mm),

adjust the distance to 1/4 inch (6 mm) by

turning the wedge stop rod, on the right

side of the top plate, clockwise to reduce

the gap and counter-clockwise to in-

crease it.

11. Replace cracked, worn, or damaged parts with

new parts. Replace all loose mounting bolts with

5/8–11 SAE grade 8 bolts, grade C locknuts, and

hardened washers. Do not re-use bolts, nuts,

and washers on fifth wheel mountings.

12. After inspecting the fifth wheel, lubricate all mov-

ing parts with a chassis or multipurpose grease.

Apply a generous coating of grease to the top

plate to fill the grooves, or depressions, on the

top plate. See

MOP 31–03 for lubrication instruc-

tions.

Jost

1. Disconnect the tractor from the trailer. For in-

structions, see the 108SD and 114SD Driver’s

Manual.

2. Thoroughly steam clean the fifth wheel.

3. Check the mounting for missing or damaged fas-

teners, and broken components. Replace or re-

pair as needed.

4. Inspect the bracket pin bolts. Make sure the lock-

ing tabs are properly securing the bolts in place.

See

Fig. 5.

5. Check the fifth wheel for bent, worn, or broken

parts. Replace as needed.

6. If the fifth wheel is equipped with low-lube plates,

check the plates and replace if damaged or worn

down to the securing bolts. It is normal for out-

side edges of the plate to pucker slightly; this

does not affect performance.

7. Check the fifth wheel adjustment. Using a lock

tester, lock and unlock the fifth wheel several

times. Make sure that the locking mechanism

works properly.

04/11/2011

f310887

A

B

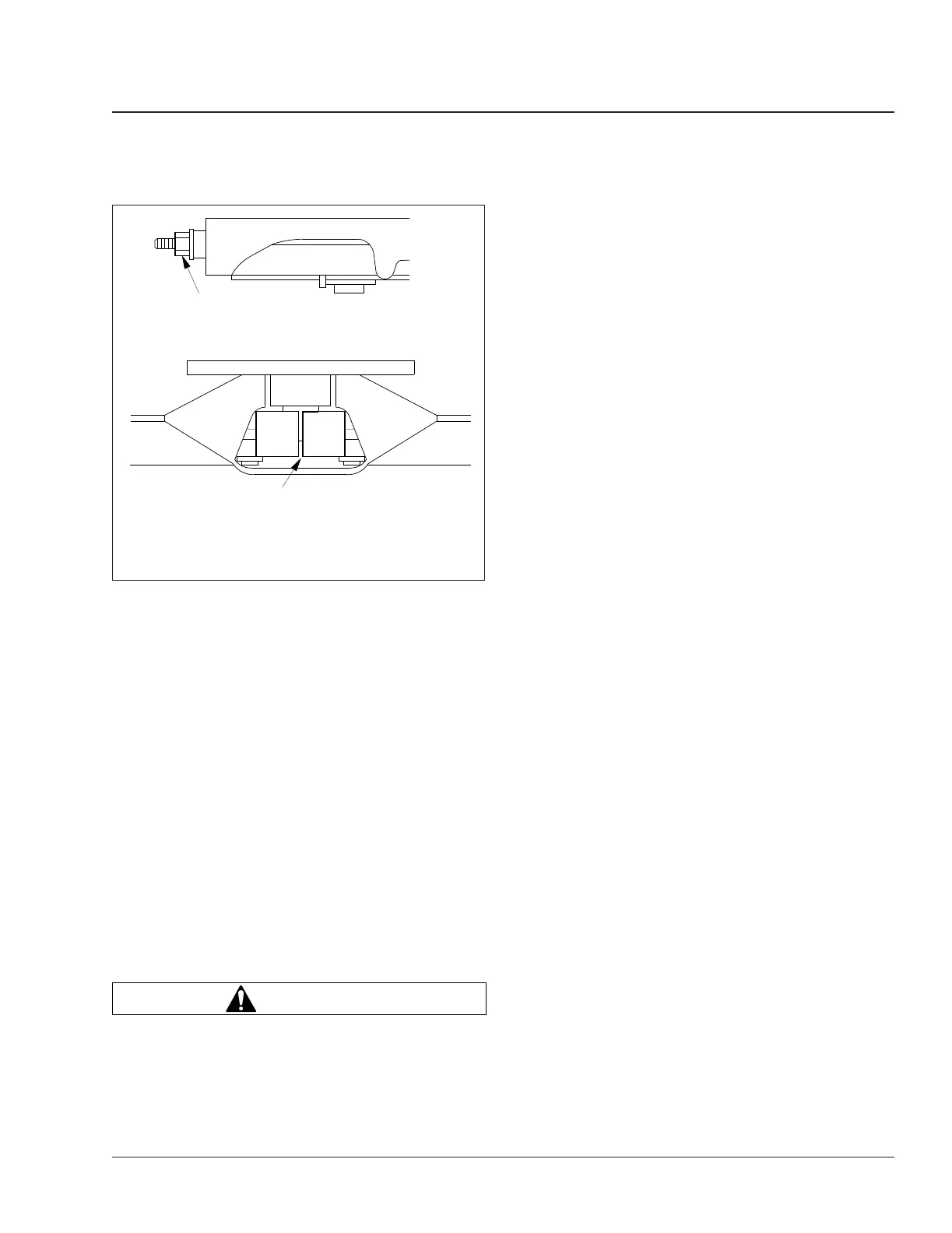

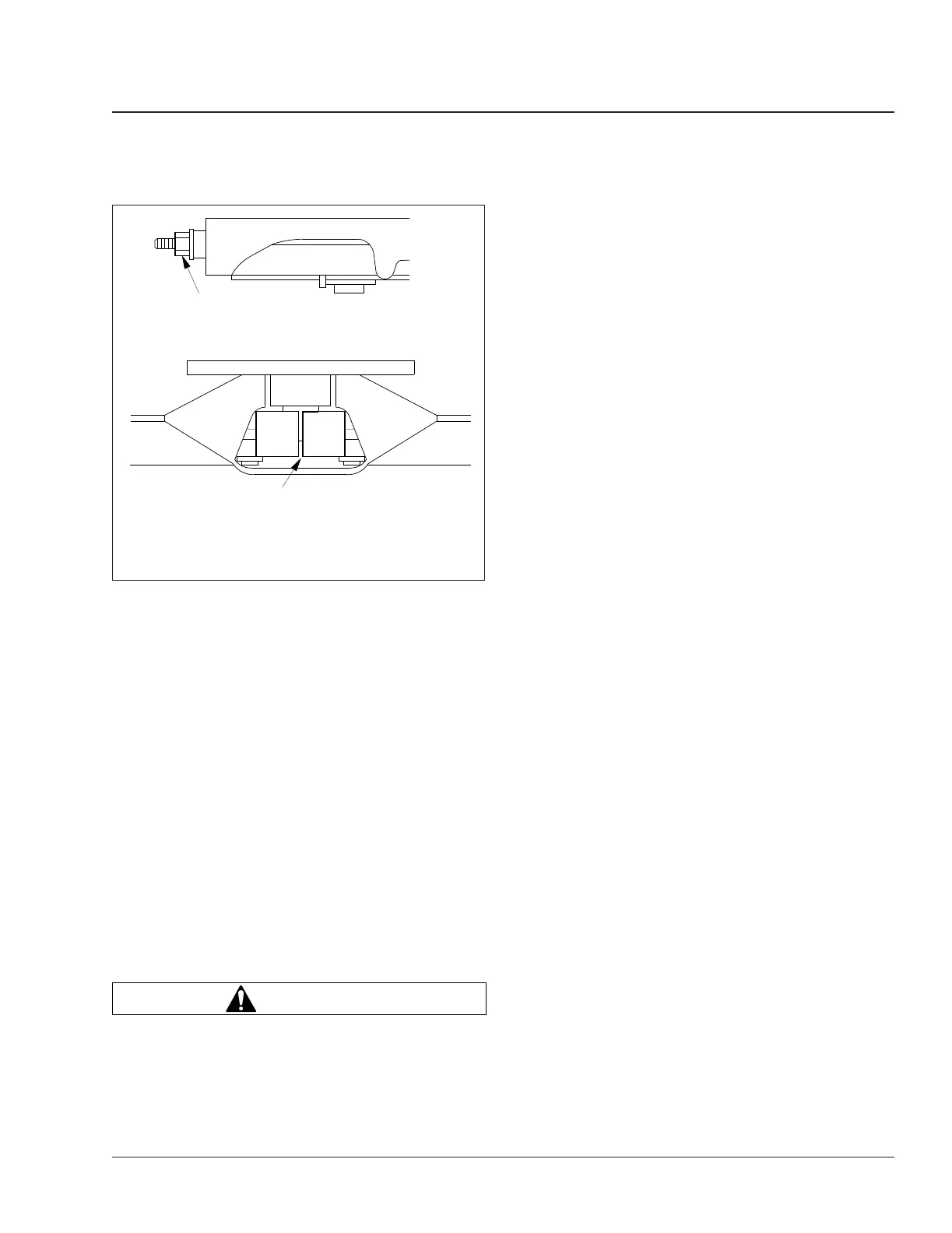

A. The nut and washer should be snug against the fifth

wheel.

B. The locks should be completely closed around the

kingpin.

Fig. 3, Holland Fifth Wheel Properly Closed

Frame and Frame Components 31

108SD and 114SD Maintenance Manual, May 2018 31/3

Loading...

Loading...