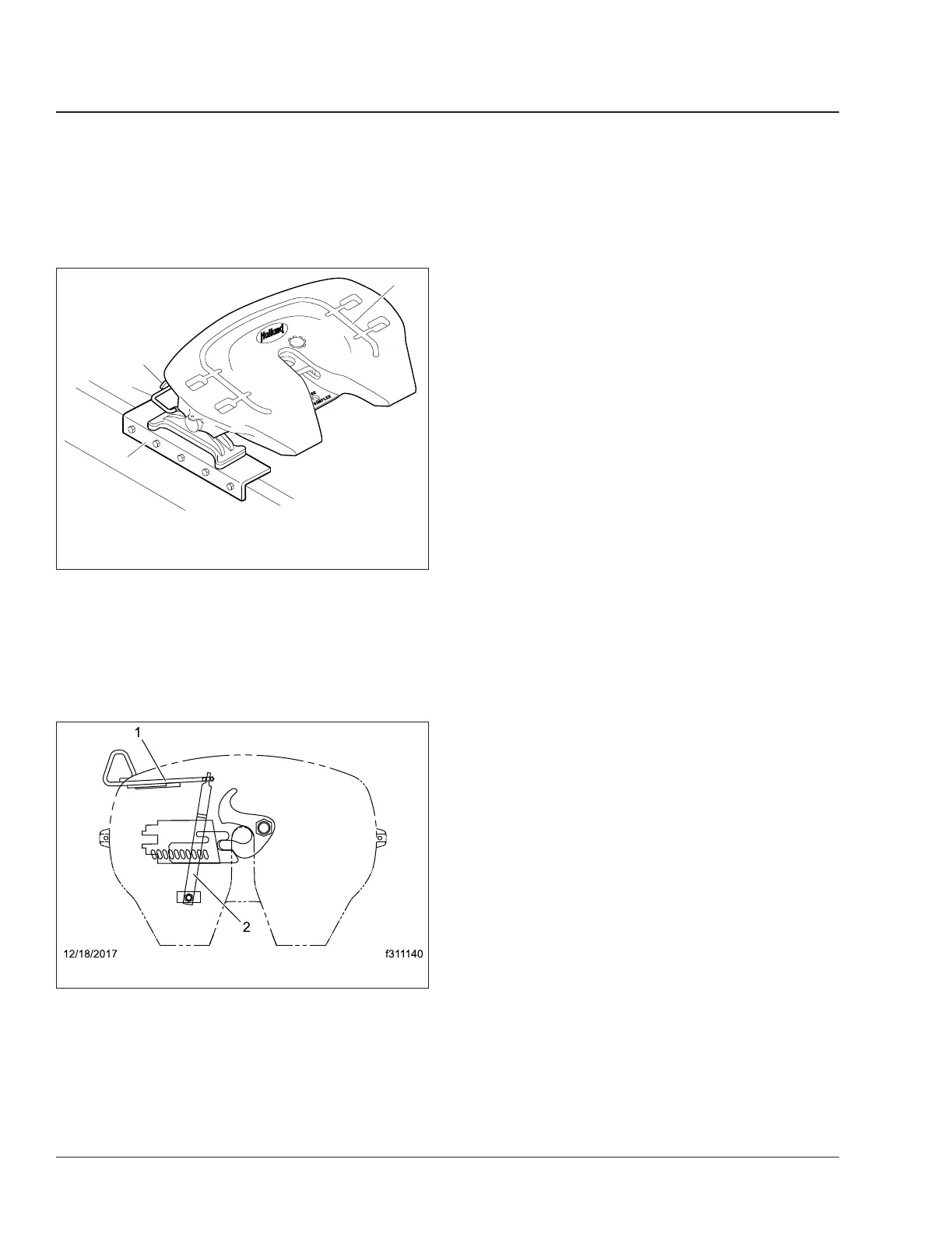

4. When the wheel is locked, the safety latch must

swing free and fall freely into position. See

Fig. 1.

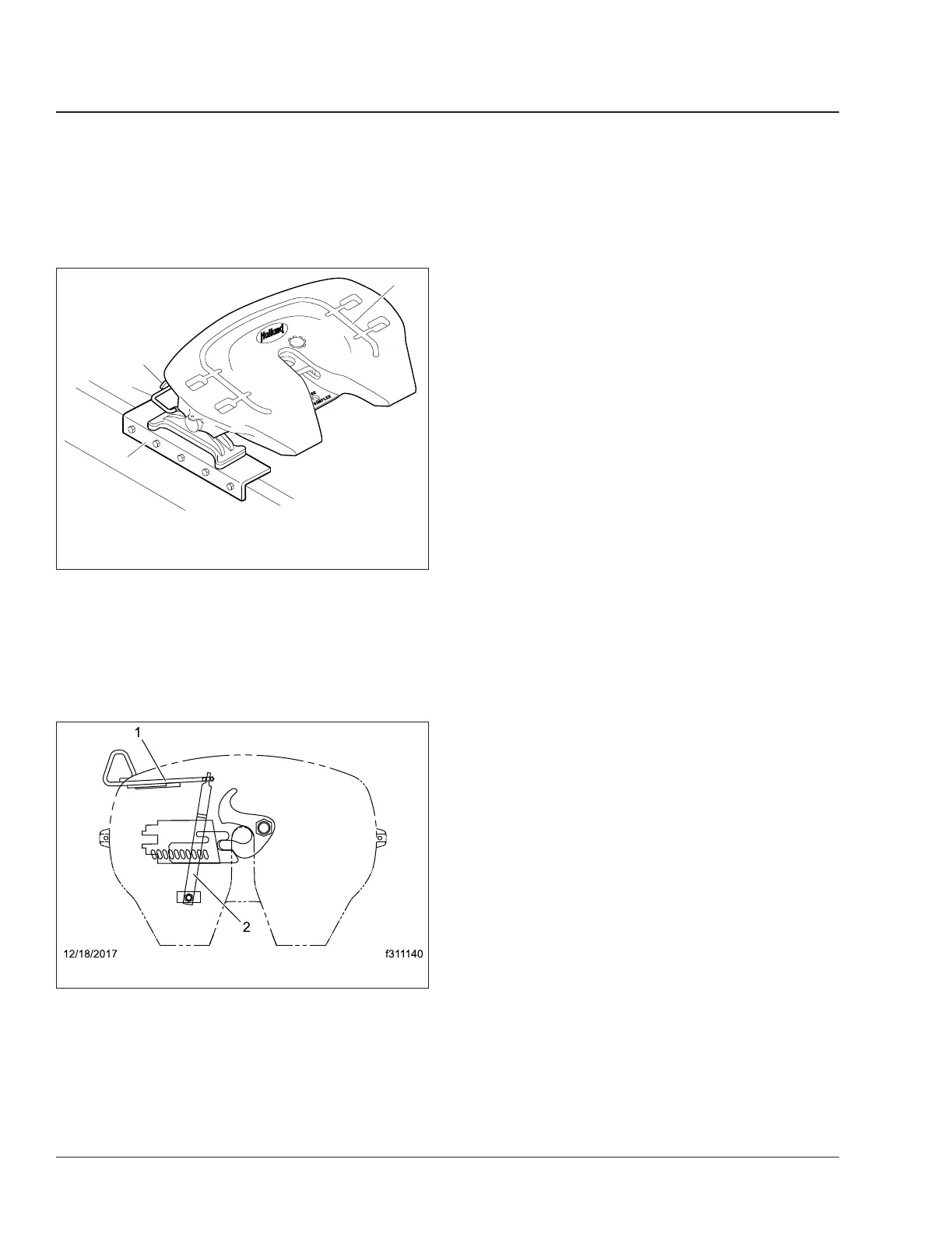

5. The lever bar and release handle must be in

proper alignment. See

Fig. 2. Compare the lever

bar and release handle alignment to a new, or a

properly operating lever bar and release handle.

Replace any bent or misaligned lever bar or re-

lease handle.

6. Check all cotter pins for cracking or damage. Re-

place any cotter pin that shows any signs of

damage.

7. Check all mounting bolts for signs of fatigue, and

tighten them to the proper torque. For torque

specifications, see

Group 00. Inspect all angles,

plates, and brackets for cracks or other damage.

8. Replace cracked, worn, or damaged parts with

new parts. Replace all loose mounting bolts with

5/8–11 SAE grade 8 bolts, grade C locknuts, and

hardened washers. Do not re-use bolts, nuts,

and washers on fifth wheel mountings.

9. After inspecting the fifth wheel, lubricate all mov-

ing parts with a chassis or multipurpose grease.

See

MOP 31–03 for lubrication instructions.

Holland FW35

1. Thoroughly steam clean all fifth wheel compo-

nents before inspection.

2. Check for cracks in the fifth wheel assembly,

mounting brackets, and mounting parts.

3. Check the fastener torques on the fifth wheel

assembly and fifth wheel mounting. Tighten bolts

and nuts as needed. Replace missing or dam-

aged bolts.

4. Inspect the fifth wheel for bent, worn, damaged,

and missing parts; replace them as needed with

genuine Holland parts.

5. Using a Holland Kingpin Lock Tester (Holland

tool number TF-TLN-5001, available through the

PDCs as HLD TFTLN5001), check the operation

of the locking mechanism by opening and closing

the locks. See

Fig. 3.

6. After inspecting the fifth wheel, lubricate all mov-

ing parts with a chassis or multipurpose grease.

See

MOP 31–03 for lubrication instructions.

Fontaine

1. Disconnect the tractor from the trailer. For in-

structions, see the 108SD and 114SD Driver’s

Manual.

2. Thoroughly steam clean the fifth wheel.

3. Check for cracks in the fifth wheel assembly,

mounting brackets, and mounting parts.

4. Ensure that both bracket pins are in place and

secured by retainer pins and cotter pins. See

Fig. 4.

5. For fifth wheels equipped with bracket liners,

rock the fifth wheel. If it does not rock freely, re-

f311052

10/29/2007

1

2

3

4

1. Lubricant Grooves

2. Safety Latch

3. Release Handle

4. Mount

Fig. 1, Holland FWS1 Fifth Wheel

1. Release Handle 2. Lever Bar

Fig. 2, Lever Bar and Release Handle Alignment

Frame and Frame Components31

108SD and 114SD Maintenance Manual, May 201831/2

Loading...

Loading...