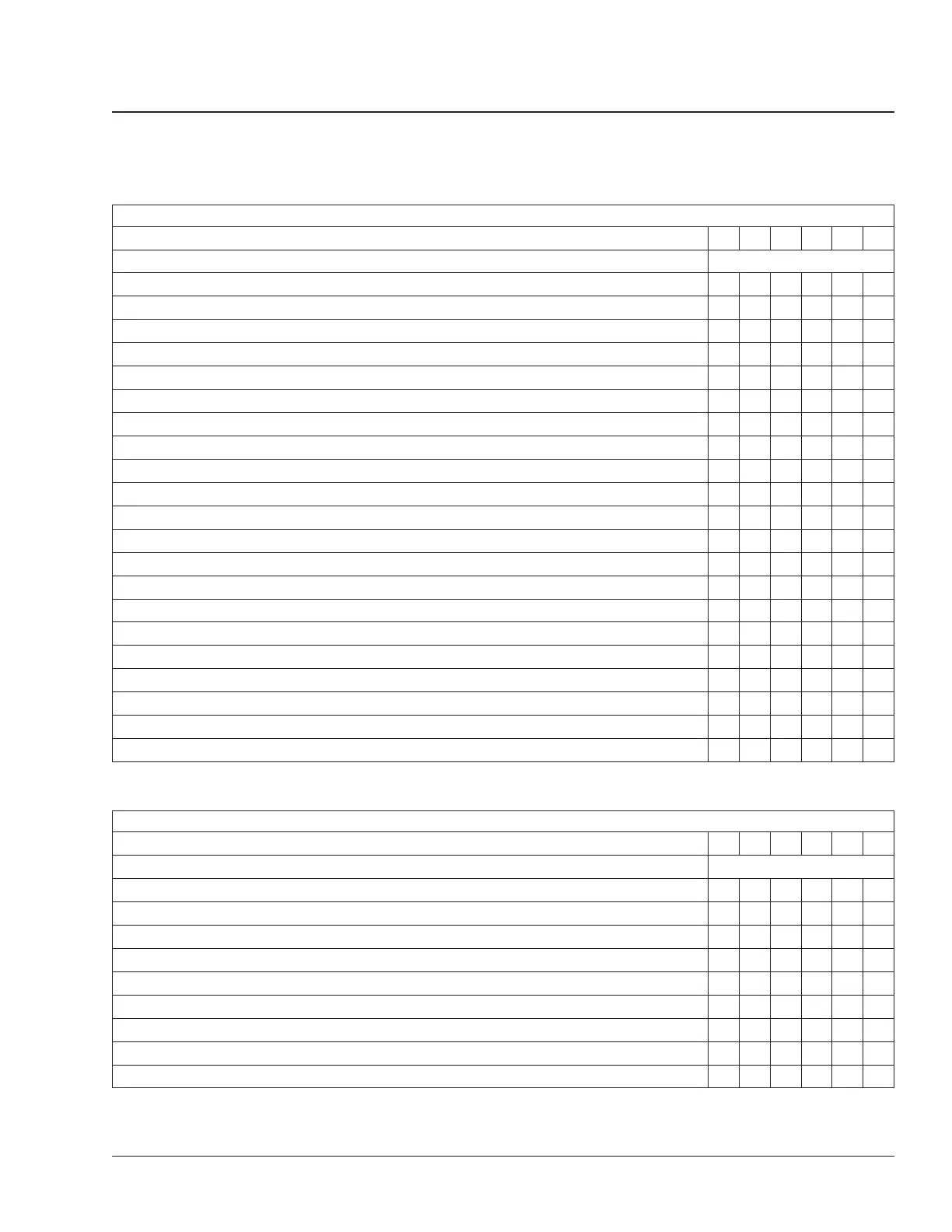

Maintenance Operation Sets for Groups 31 through 41

REQUIRED MAINTENANCE OPERATION SET IM M1 M2 M3 M4 M5

Maintenance Operation Number and Operation Description

31–01 Frame Fastener Torque Checking • • •

31–02 Fifth Wheel Inspecting ••••••

31–03 Fifth Wheel Lubricating ••••••

31–04 Holland Fifth Wheel Sliding Mechanism Inspecting • • •

32–01 Suspension Inspecting ••••••

32–02 Suspension Lubricating ••••••

32–03 U-Bolt Torque Checking • • • •

33–01 Knuckle Pin Lubricating ••••••

33–02 Tie-Rod End Inspecting ••••••

33–03 Tie-Rod End Lubricating ••••••

33–04 All-Axle Alignment Checking • • •

33–05 All-Wheel-Drive Front Axle Oil Level Checking • • •

33–06 All-Wheel-Drive Front Axle Oil Changing • • •

35–01 Axle Lubricant Level Checking • • •

35–02 Axle Breather Checking ••••••

35–03 Axle Lubricant Changing and Magnetic Plug Cleaning • • •

35–04 Two-Speed-Axle Shift Unit Oil Level Checking (for FL112s, perform at M1 interval) • •

35–05 Two-Speed-Axle Shift Unit Oil Changing • • •

40–01 Wheel Nut Checking •••

41–01 Driveline Inspecting ••••••

41–02 Driveline Lubricating ••••••

Table 11, Maintenance Operation Sets for Groups 31 through 41

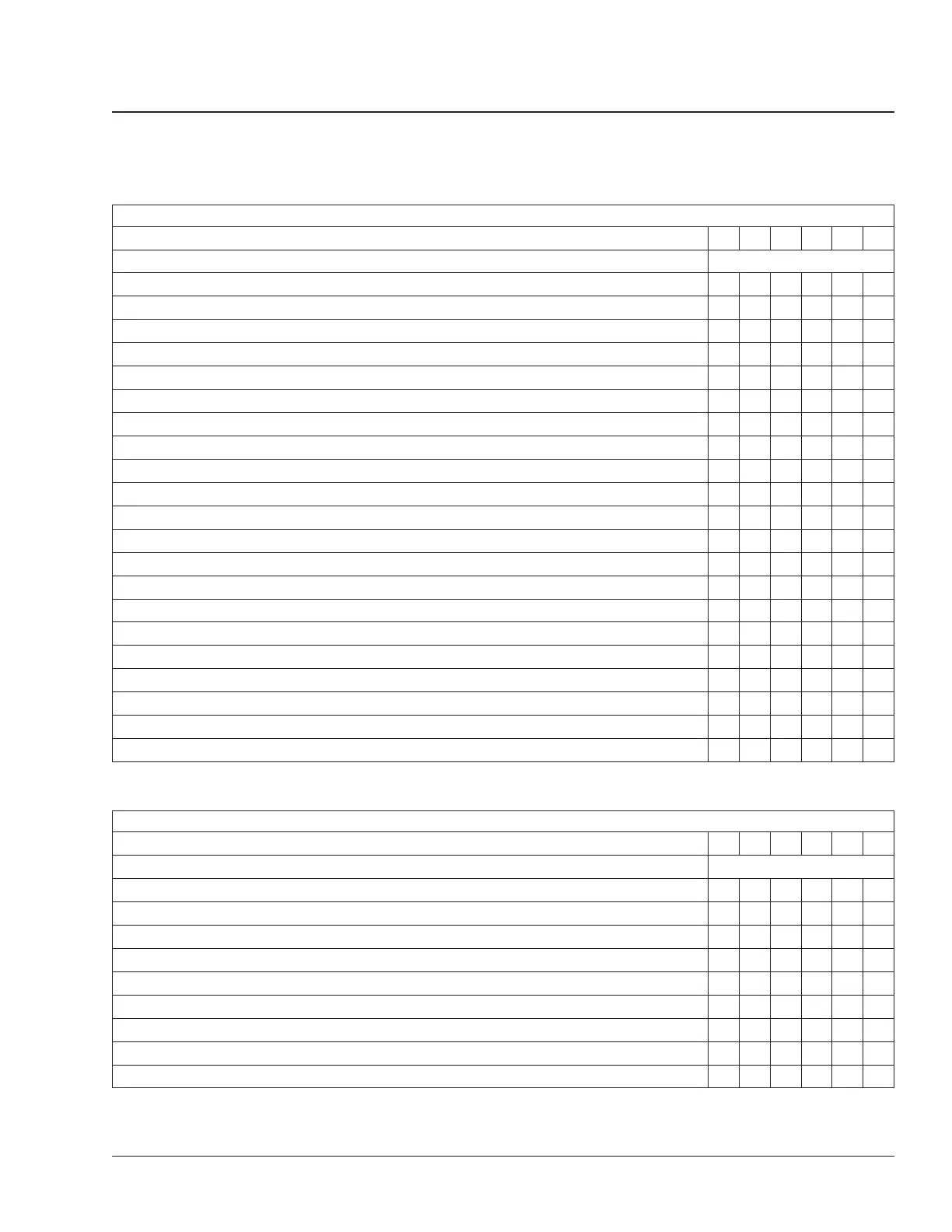

Maintenance Operation Sets for Group 42

REQUIRED MAINTENANCE OPERATION SET IM M1 M2 M3 M4 M5

Maintenance Operation Number and Operation Description

42–01 Air Dryer Inspecting, Bendix AD–9 ••••••

42–02 Air Brake Valve Inspecting and Leak Checking, Bendix BP–R1 ••••••

42–03 Foot Brake Valve Actuator Lubricating, Bendix E–12 ••••••

42–04 Air Brake Valve Operation Checking, Bendix BP–R1 and E–12 ••••••

42–05 Relay Valve Checking, Midland ••••••

42–06 Quick Release and Flipper Valves Checking, Midland ••••••

42–07 Brake Chamber Inspecting (All Models) ••••••

42–08 Air Dryer Desiccant Replacing, Meritor WABCO System Saver 1000 •

42–09 Brake Adjusting, Manual Slack Adjusters ••••••

General Information 00

Maintenance Operation Sets Tables: 00–08

Business Class Trucks Maintenance Manual, February 2004 00/13

Loading...

Loading...