RWB II ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

S70-210 IOM

Page 12

OIL TEMPERATURE CONTROL - Oil temperature will gen-

erally run about 15 - 35°F above condensing temperature.

In many cases, an oil temperature control is not required if

condensing temperature is above 65°F as oil temperature

can be allowed to float with condenser temperature.

Condensing Temperature: 65°F - 105°F

Oil Temperature: 80°F - 140°F

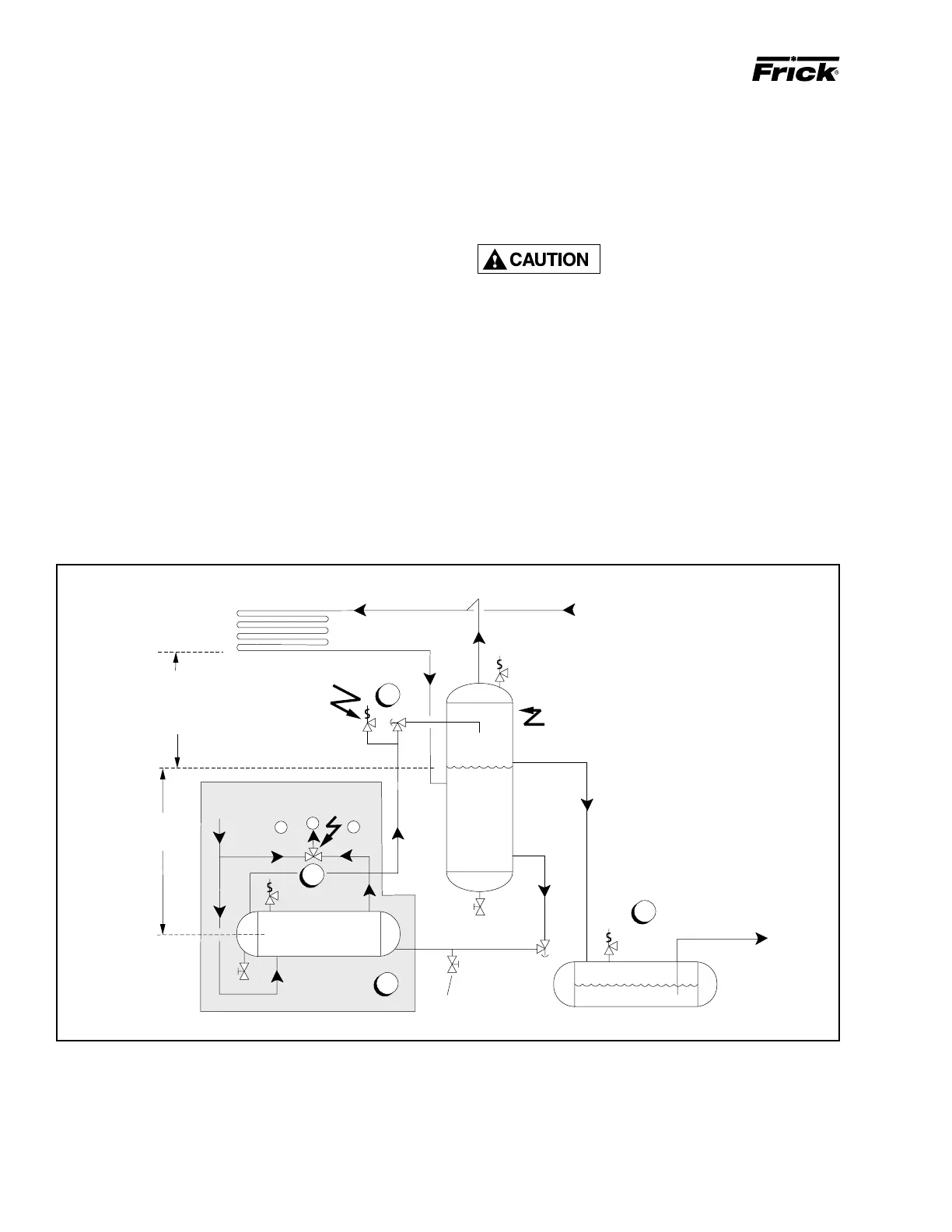

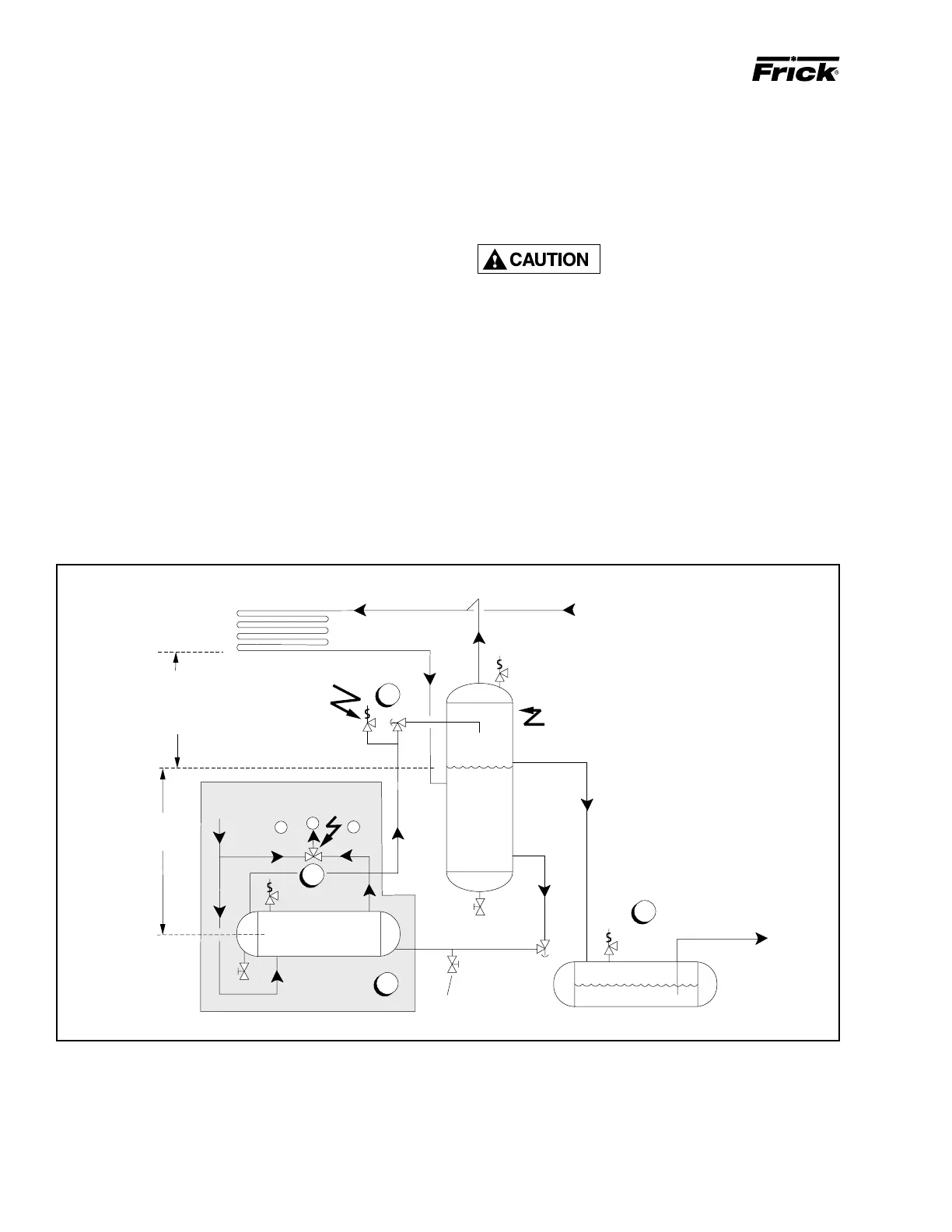

INSTALLATION - The shell and tube-type thermosyphon oil

cooler with oil-side piping and a thermostatically controlled

mixing valve (if ordered) are factory mounted and piped. The

customer must supply and install all piping and equipment

located outside of the shaded area on the piping diagram

with consideration given to the following:

1. The refrigerant source, thermosyphon or system receiver,

should be in close proximity to the unit to minimize piping

pressure drop.

2. The liquid level in the refrigerant source must be 6 to 8

feet minimum above the center of the oil cooler.

3. A safety valve should be installed if refrigerant isolation

valves are used for the oil cooler.

TSOC AND WCOC OIL SIDE SAFETY RELIEF - Compres-

sor units assembled after January 1995, which have valves

in the oil piping to isolate the oil cooler from the oil separator

for servicing, may have factory installed piping to relieve the

shell side (oil side) safety valve directly into the oil separator,

as shown in the P & I diagrams section.

This arrangement uses a special UV stamped safety valve

rated for liquid and vapor relief. The safety valve is designed

for 500 psi DWP and is set to relieve at 75 psi delta P. The

safety valve piping contains flanged connections should the

valve require maintenance or replacement.

EXTRA CAUTION SHOULD BE

USED WHEN SERVICING AN OIL

SEPARATOR WITH THIS ARRANGE-

MENT. IF THE OIL COOLER IS VALVED OFF FROM AN

OIL SEPARATOR WHICH HAS BEEN EVACUATED FOR

SERVICING, THEN THE OIL COOLER COULD RELIEVE

INTO THE SEPARATOR VESSEL IF THE 75 PSI DELTA P

SETPOINT IS EXCEEDED.

Other units, which do not use this special safety valve ar-

rangement, will have factory mounted safety valves on the

shell side of the oil cooler which the installing contractor

should pipe into house safety systems designated suitable

for oil relief.

The component and piping arrangement shown in Figure

11 is intended only to illustrate the operating principles of

thermosyphon oil cooling. Other component layouts may be

better suited to a specific installation. Refer to publication

E70-900E for additional information on Thermosyphon Oil

Cooling.

Figure 11

1.

The thermosyphon oil cooler is supplied with oil side piped to the compressor unit and stub ends supplied on refrigerant side.

2. A three-way oil temperature control valve is required where condensing temperature is expected to go below 65°F.

3. A refrigerant-side safety valve is required in this location only when refrigerant isolation valves are installed between the cooler and

thermosyphon receiver. If no valves are used between the cooler and TSOC receiver, the safety valve on the TSOC receiver must be

sized to handle the volume of both vessels. Then, the safety valve on the cooler vent (liquid refrigerant side) can be eliminated.

4. The system receiver must be below the thermosyphon receiver in this arrangement.

B

C

A

OIL TEMP

CONTROL VALVE

HO

T

COOL

OIL OU

T

HOT OIL IN

THERMOSYPHON

OIL COOLER

LIQUID

LEVEL

STATIC HEAD

TO OVERCOME

CONDENSER

PRESSURE DROP

8 Ft

.

Min.

SYSTEM

CONDENSER

SAFET

Y

VALV

E

VAPOR

THERMOSYPHON

RECEIVER

LIQUID OVERFLOW

DRAIN TO

RECEIVER

TO

SYSTEM

EVAPORATO

R

SYSTEM

RECEIVER

1

3

4

(Mounted below Thermosyphon

receiver level)

2

TSOCA

Refrigerant-side drain valve

required for plate-type

thermosyphon oil coolers.

Loading...

Loading...