RWB II ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

S70-210 IOM

Page 14

For refrigeration plants using a Packaged Refrigerant Recir-

culation (PRR) unit and a direct expansion (DX) economizer

system it is necessary to operate the liquid feed solenoid on

the PRR unit and the liquid feed solenoid on the DX vessel

off of a common signal to avoid liquid overfeed on the DX

economizer system.

ECONOMIZER LOAD BALANCING

The most energy efficient manner to operate an economizer

system, when using multiple compressors on a common

economizer vessel, is to take as much of the flash gas as

possible to the compressors that are fully loaded. This can

be done in at least two ways.

1. Use the economizer output from the microprocessor to

turn off a solenoid, or to actuate the electric shutoff option

on a back-pressure regulator, based on percent of slide valve

travel. This will direct all the flash vapor to the other loaded

compressors.

2. A dual-setpoint back-pressure regulator valve can be used

in each of the individual economizer vapor lines. When a com-

pressor is running near full load, the BPR valve will operate

on the desired setpoint, or basically wide open, to minimize

pressure drop in the line. When one compressor unloads

below the slide valve position where the economizer output

on the microprocessor turns on, the dual-setpoint feature of

the regulator can be actuated by this output to control the

pressure, on the vessel side of the regulator, to be a few psi

higher. Consequently, the flash gas will be sent to the loaded

compressors first, until they can’t handle all the vapor and

the pressure in the vessel starts to rise. Then, some of the

vapor will go to the unloaded compressor to help maintain

the vessel at the desired pressure. An example of a back-

pressure regulator with electric shutoff and the dual-setpoint

feature is an R/S A4ADS.

ELECTRICAL

NOTE: Before beginning electrical installation, read

the instructions in the section "Proper Installation of

Electronic Equipment".

RWB II units are supplied with a QUANTUM

™

control system.

Care must be taken that the controls are not exposed to physi-

cal damage during handling, storage, and installation. The

microprocessor enclosure cover must be kept tightly closed

to prevent moisture and foreign matter from entering.

All customer connections are

made in the Quantum control panel

mounted on the unit. This is the

ONLY electrical enclosure and should be kept tightly

closed whenever work is not being done inside.

MOTOR STARTER PACKAGE

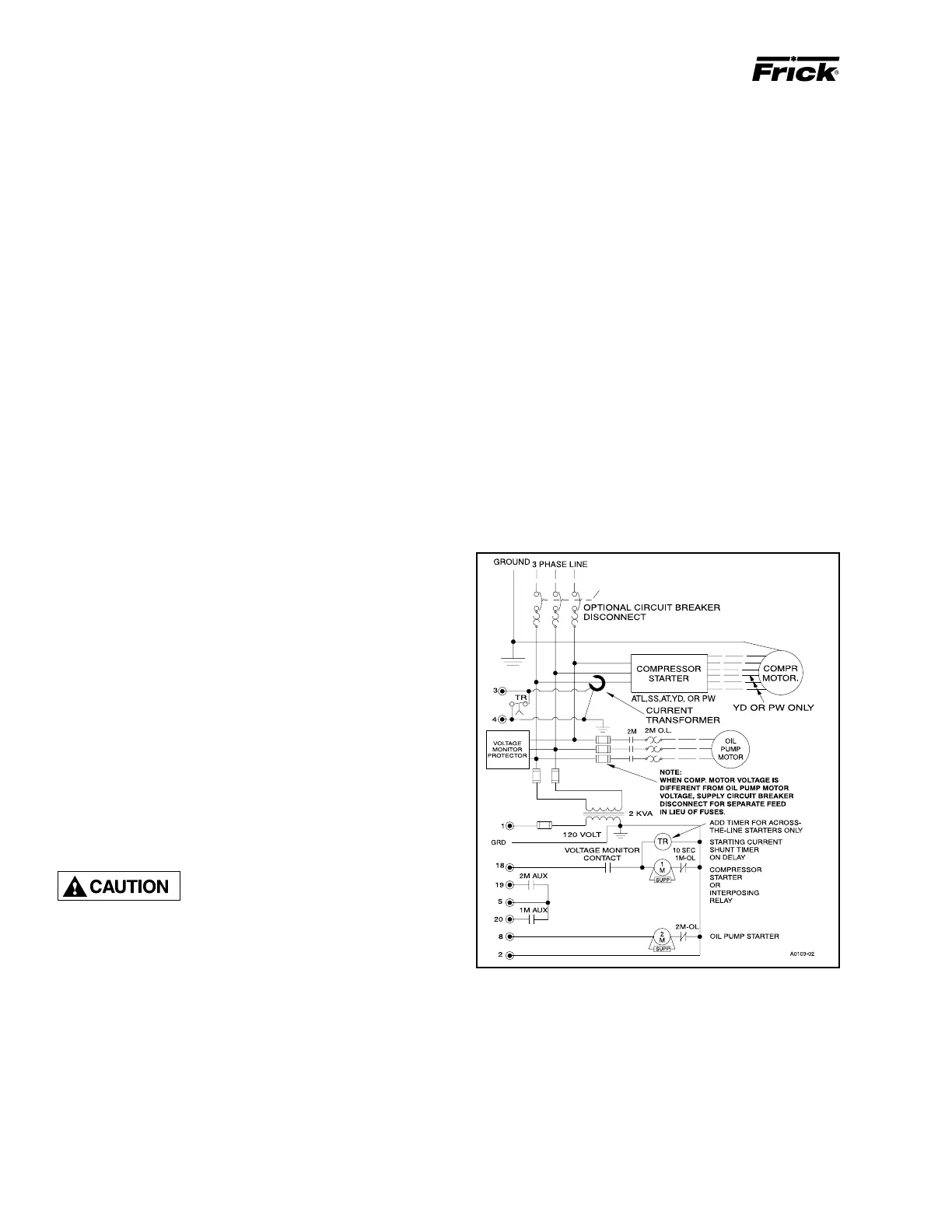

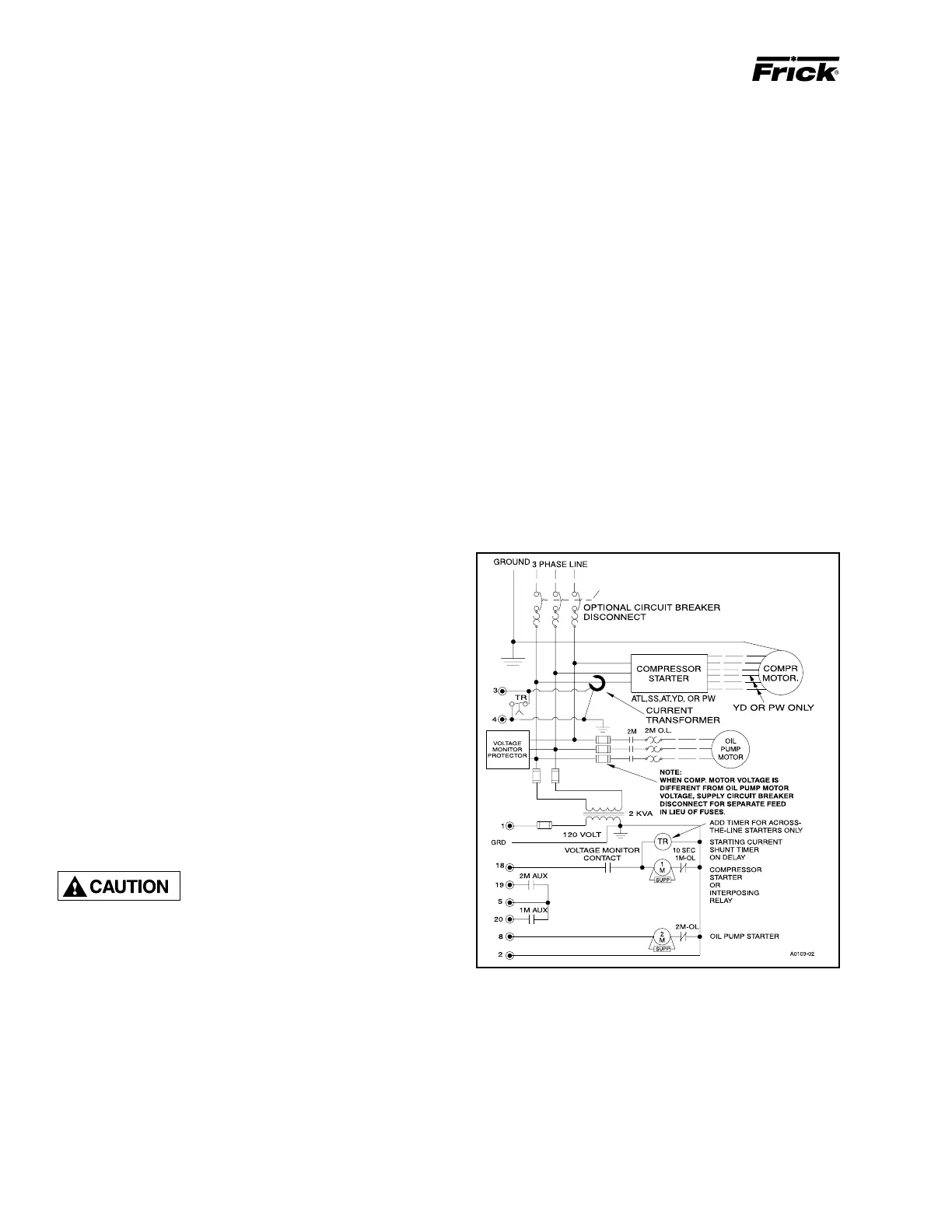

Motor starter and interlock wiring requirements are shown in

the wiring diagram above. All the equipment shown is sup-

plied by the installer unless a starter package is purchased

from Frick. Starter packages should consist of:

1. The compressor motor starter of the specified HP and

voltage for the starting method specified (across-the-line,

autotransformer, wye-delta, or solid-state).

NOTE: If starting methods other than across-the-line are

desired, a motor/compressor torque analysis must be

done to ensure that sufficient starting torque is available,

particularly in booster applications. Contact FRICK if

assistance is required.

2. If specified, the starter package can be supplied as a

combination starter with circuit breaker disconnect. However,

the motor overcurrent protection/disconnection device can

be applied by others, usually as a part of an electrical power

distribution board.

3. The oil pump starter with fuses, or in the case where the

compressor motor is a different voltage from the oil pump

motor, with a circuit breaker disconnect suitable for separate

power feed.

4. A 2.0 KVA control power transformer (CPT) to supply 120

volt control power to the microprocessor control system and

separator oil heaters is included. If environmental conditions

require more than the usual two 500 watt oil heaters, an ap-

propriately oversized control transformer will be required. If

frequent power fluctuations are anticipated or extremely noisy

power lines are encountered, a regulating control transformer

should be considered. Contact FRICK for assistance.

5. For customer-supplied across-the-line starters, a shunt-

ing devicemust be installed across the Current Transformer

(terminals 3 & 4).

If the shunting device is not installed, the SBC board may

be severly damaged at start-up (see Figure 16).

Figure 16 - Starter Wiring Diagram

6. The compressor motor Current Transformer (CT) is in-

stalled on any one phase of the compressor leads.

NOTE: The CT must see all the current of any one phase,

therefore in wye-delta applications BOTH leads of any

one phase must pass through the CT.

7. One each normally open compressor motor and oil pump

motor starter auxiliary contact should be supplied and in

addition to the compressor and oil pump motor starter coils,

the CT and CPT secondaries wired as shown on the starter

Loading...

Loading...