RWB II ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

S70-210 IOM

Page 9

COMPRESSOR OIL

DO NOT MIX OILS of different

brands, manufacturers, or types.

Mixing of oils may cause exces-

sive oil foaming, nuisance oil level cutouts, oil pressure

loss, gas or oil leakage and catastrophic compressor

failure.

Use only Frick

®

refrigeration oil

and filters or warranty claims may

be denied.

The oil charge shipped with the unit is the best suited lu-

bricant for the conditions specified at the time of purchase.

If there is any doubt due to the refrigerant, operating pres-

sures, or temperatures, refer to Frick Pub. E160-802 SPC

for guidance.

INITIAL OIL CHARGE

The initial charging level is midway in the top sight glass

located midway along the oil separator shell (the sight glass

is located in the lower portion of the vertical separator).

Normal operating level is midway between the top sight

glass and bottom sight glass. The following table gives the

approximate oil charge quantity.

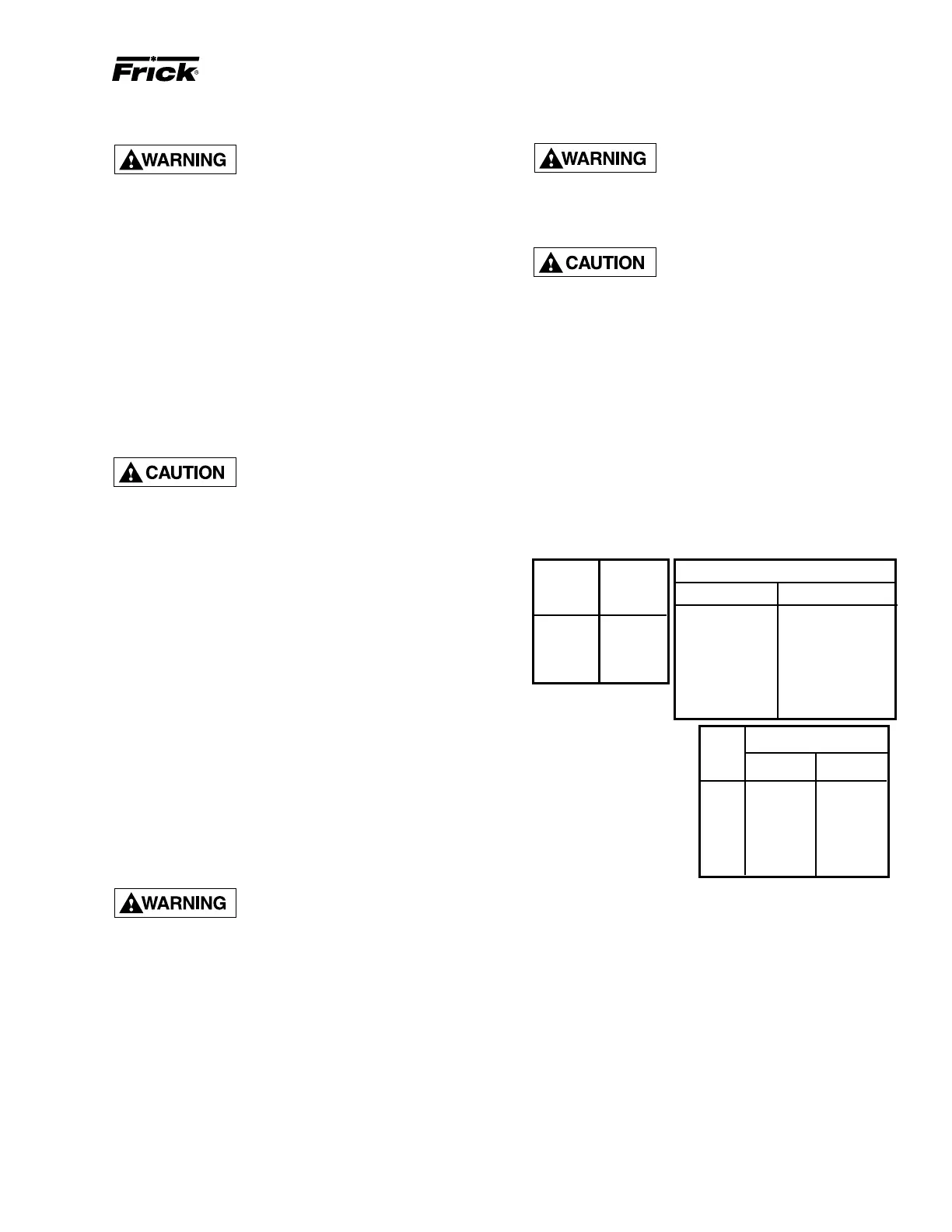

TABLE - BASIC OIL CHARGE (Gal)

* Includes total in oil sep-

arator and piping. Add

additional for oil cooler.

Add oil by attaching the end of a suitable pressure type

hose to the oil charging valve, located on the top of the oil

separator on the compressor end of the separator. Using a

pressure-type pump and the recommended Frick oil, open

the charging valve and pump oil into the separator. NOTE:

Fill slowly because oil will fill up in the separator faster

than it shows in the sight glass.

Oil distillers and similar equipment which act to trap oil must

be filled prior to unit operation to normal design outlet levels.

The same pump used to charge the unit may be used for

filling these auxiliary oil reservoirs.

NOTE: The sight glass located in the coalescing end

of the separator near the discharge connection should

remain empty.

496 (1)

676 (1)

856 (1)

1080 (1)

HOT ALIGNMENT OF COMPRESSOR/MOTOR

Hot alignments can only be made

after the unit has operated for sev-

eral hours and all components are

at operating temperatures.

Shut down the unit (proper lockout/tagout procedures

should be followed) and QUICKLY affix dial indicator to

coupling motor hub, then take readings of both the face and

rim of the compressor hub. If these readings are within toler-

ance, record reading, attach coupling guard and restart unit.

However, if the reading is not within limits, compare the hot

reading with the cold alignment and adjust for this difference;

i.e. if the rim at 0° and 180° readings indicates that the motor

rises .005" between its hot and cold state, .005" of shims

should be removed from under the motor.

After the initial hot alignment adjustment is made, restart unit

and bring to operating temperature. Shut down and recheck

hot alignment. Repeat procedure unit hot alignment is within

specified tolerance.

INSTALL COUPLING GUARD BE-

FORE OPERATING COMPRES-

SOR.

OIL PUMP COUPLING

Compressor units with prelube and direct motor/pump cou-

pled pumps need no pump/motor coupling alignment since

this is maintained by the close-coupled arrangement.

Some units utilize full and cycling lube pumps which have the

motor separate from the pump. These must be checked for

alignment due to possible misalignment which may be caused

by shipping and handling. Adjustments for that maximum mis-

alignment is less than 0.010" Total Indicator Runout (T.I.R.).

Failure to align the coupling may cause serious damage to the

pump, shaft seal, coupling, and motor bearings. Use the same

procedure as compressor/motor coupling alignment.

HOLDING CHARGE AND STORAGE

Each RWB II compressor unit is pressure and leak tested at

the Frick factory and then thoroughly evacuated and charged

with dry nitrogen to ensure the integrity of the unit during

shipping and short term storage prior to installation.

NOTE: Care must be taken when entering the unit to

ensure that the nitrogen charge is safely released.

Holding charge shipping gauges

on separator and external oil cooler

are rated for 30 PSIG and are for

checking the shipping charge only. They must be re-

moved before pressure testing the system and before

charging the system with refrigerant. Failure to remove

these gauges may result in catastrophic failure of the

gauge and uncontrolled release of refrigerant resulting

in serious injury or death.

All units must be kept in a clean, dry location to prevent

corrosion damage. Reasonable consideration must be

given to proper care for the solid-state components of the

microprocessor.

Unit which will be stored for more than two months must have

the nitrogen charge checked periodically.

BASIC*

CHARGE

(gal.)

RWB II

PLUS

MODEL

ADDITIONAL FOR OIL COOLER

REQ'D. (gal.)SIZE (in.)

6 X 60 6

8 X 60 10

6 X 120 12

8 X 120 20

10 X 120 28

12 X 120 39

16 X 120 45

1. Oil Basic Oil Charge

Sep.

Dia. Vertical Horiz.

42" 165 gal. 245 gal.

48" 220 gal. 330 gal.

54" 275 gal. –

60" 385 gal. –

66" 385 gal. –

72" 385 gal. –

Loading...

Loading...