VYPER

™

VARIABLE SPEED DRIVE

INSTALLATION

100-200 IOM (FEB 09)

Page 23

Figure 16

cutout on the back wall of the Vyper

™

cabinet (See Figure 15).

Output power connections should be tightened as shown in

the table. An appropriate conduit must be connected to the

back cutout flange of the cabinet for proper installation. These

connections are made in the factory and will be pretested

before shipment. Generally, an additional dV/dt “snubber”

filter is not required for package-mounted units.

Figure 14 - Power out connection point

Output Power Lead Torque Requirement

(Package-Mounted Vyper

™

)

Connector Size Termination Torque

3/8” lug Compression 216-240 in-lb

ELECTRICAL CONDUITS

• Allpower wiring must be contained in metallic conduit.

• Allcompressormotorwiringmustbeinaseparatemetallic

conduit.

• Oil pump motor wiring must be in a separate metallic

conduit.

• Compressormotorcoolingfanpowermustbeinaseparate

metallic conduit.

• ControlwiringbetweentheQuantum

™

LX panel and the

Vyper

™

must be contained in separate metallic conduit.

• Analog wiring needs to be in separate metallic conduit.

Figure 15 - Back wall power connections

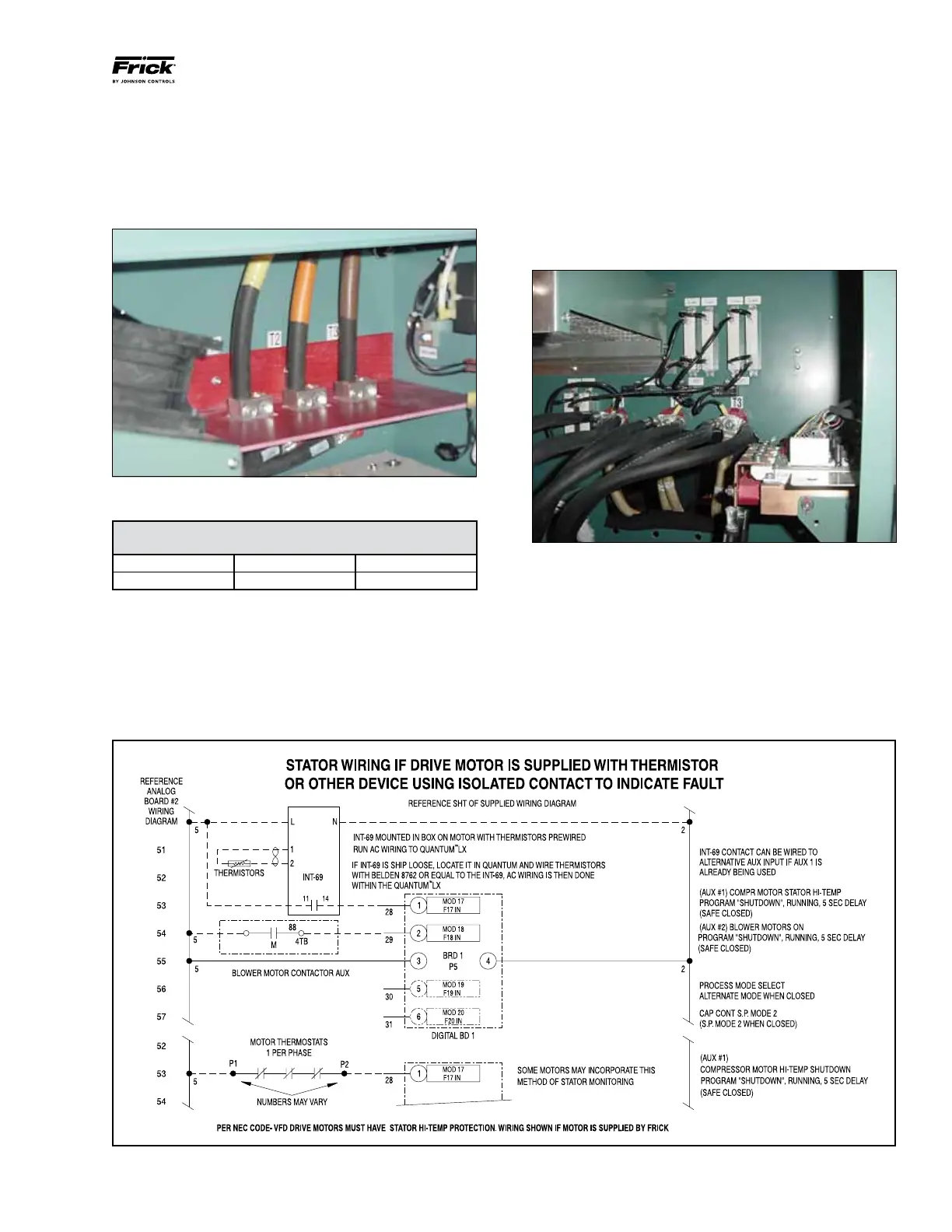

WIRING DIAGRAM OPTIONS

The National Electrical Code requires thermal protection for

motors operating with variable-speed drive systems. Frick

employs two types of thermal protection for motors. One

method uses thermistors, and one method uses RTDs. Fig-

ures 16 - 21 show the wiring scheme for both options.

MOTOR THERMISTOR PROTECTION

Loading...

Loading...