VYPER

™

VARIABLE SPEED DRIVE

MAINTENANCE

100-200 IOM (FEB 09)

Page 48

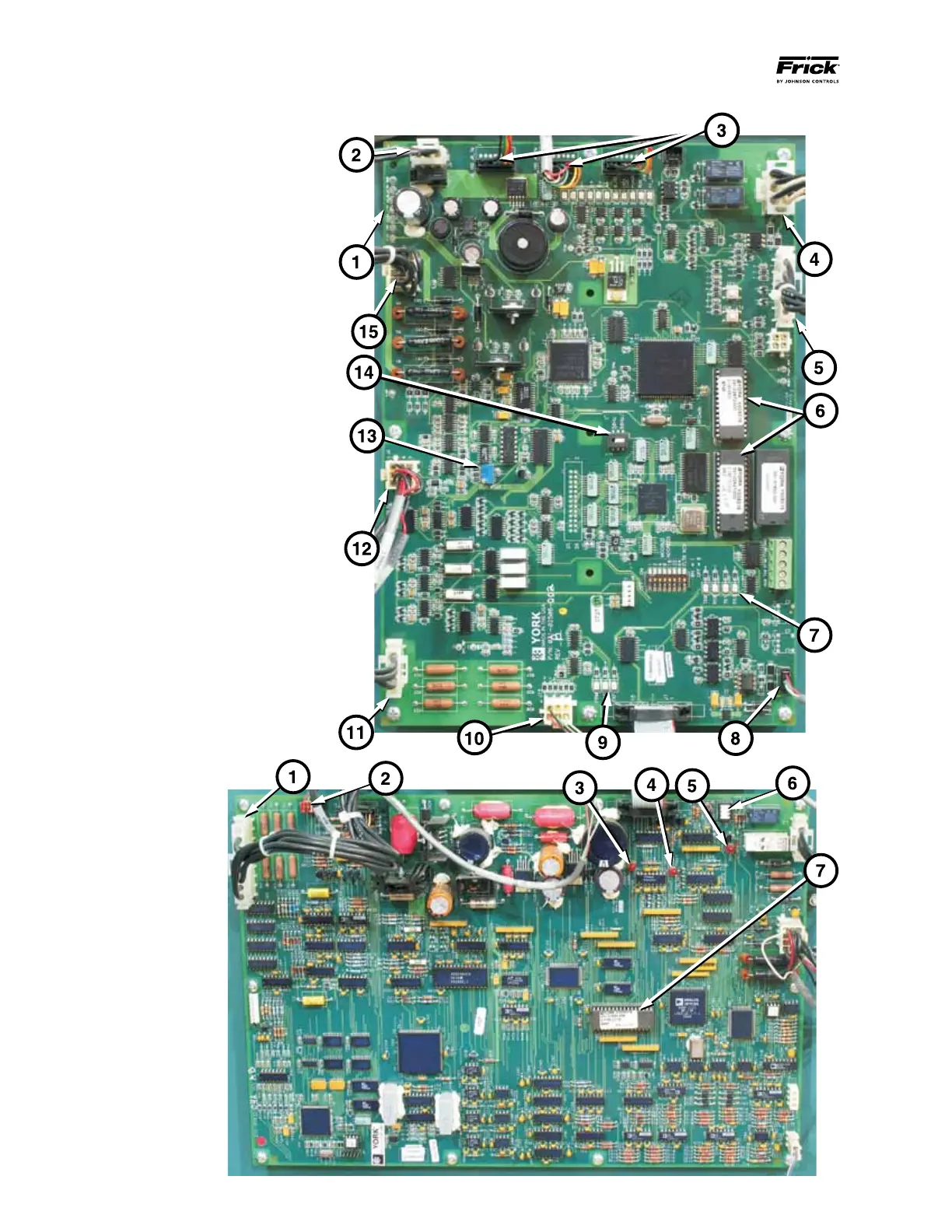

1. J5 Connector (volt-

age input / test points

2. J8 Communications

to the logic board

(J15)

3. Power Supply “OK”

LED

4. Filter “Over-Temp”

LED

5. Run LED

6. Filter ON/OFF switch

7. E-prom

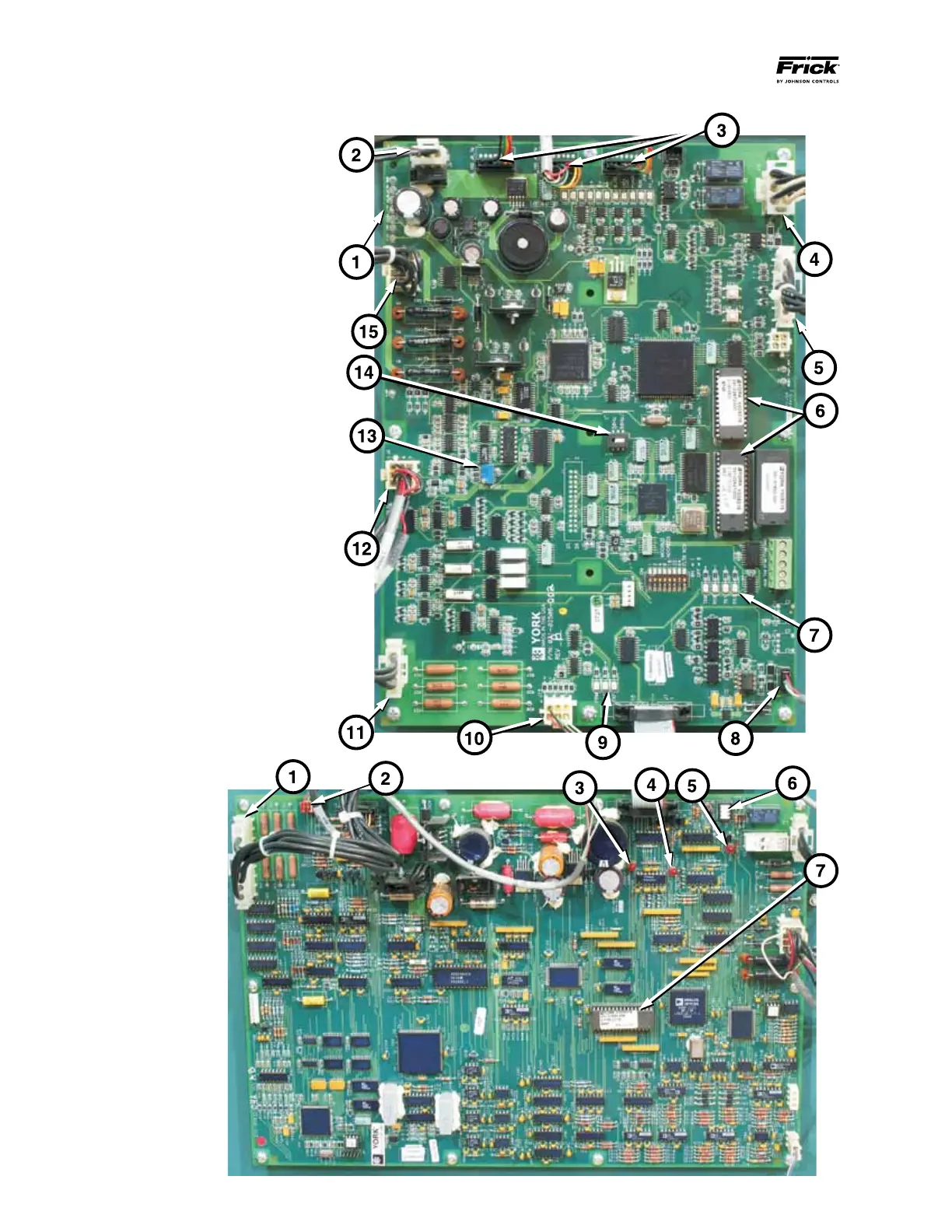

1. DC Voltage Test Points

2. 24VAC Input

3. Gate Drive Connections J8, J9 & J10

4. J12 Start Input / Run Output

5. J6 to J4 of the SCR Trigger Board

6. E-prom Chips

7. Communication Indicators RX/TX, Logic

Board to Quantum LX

8. J16 Communications Cable, Logic

Board to Quantum LX

9. Communications Indicators RX/TX,

Logic Board to Filter Board

10. J15 Communications Cable, Logic

Board to Filter Board.

11. DC Bus Voltage Input

12. J2 Remove to manually engage circula-

tion pumps and internal fans

13. JOB FLA Potentiometer

14. Frequency Switch (60/50Hz)

15. Output Current input, Phase - A, B & C

The callouts on Figures 56 and 57 point

out components, indicators and test points

that can be used to aid in maintenance

amd troubleshooting of fault codes.

Figure 56 - Control Logic Board

Figure 57 - Filter Logic

Board

Loading...

Loading...