11

Compressor

There are two types of compressors used on

dehumidifiers:

1. Permanent Split Capacitor compressor (Rotary)

2. Split Phase compressor (Reciprocating)

Permanent Split Capacitor (PSC) Compressor

This compressor has a Start and Run winding with a

capacitor wired in series with the Start winding. When

power is applied, the capacitor assists in bringing the

compressor motor to optimum speed.

Split Phase Compressor

This compressor has a Start and Run winding. On models

equipped with a current activated relay, the relay is wired

in series with the Run winding. When power is applied to

the Run winding, The high starting current pulls the relay

armature up, closing contacts to complete the circuit to

the Start winding. The motor starts and accelerates to a

point where the current is reduced enough to allow the

relay to drop out and disconnect the circuit to the Start

winding. This point occurs at about 80% of full speed.

The motor continues to accelerate to full speed on the

Run winding alone. On models with PTC relay, current is

applied to both windings at the same time. This starts the

compressor. As current flows through the relay to the Start

winding, the relay will increase in resistance . Within a

fraction of a second, the resistance will climb high enough

for the Start winding to drop out.

CAUTION: Replacement compressors are charged

with oil at the factory. Care should be exercized when

replacing a compressor to avoid spilling any oil.

To Test Compressor Motor

WARNING: WHENEVER TESTING A

COMPRESSOR, EXTREME CAUTION SHOULD

BE USED TO PREVENT DAMAGING THE

TERMINALS. A COMPRESSOR WITH A

DAMAGED TERMINAL OR A GROUNDED

WINDING CAN EXPEL A TERMINAL FROM ITS

INSULATED HOUSING WHEN THE

COMPRESSOR IS ENERGIZED. IF THIS

HAPPENS, A MIXTURE OF REFRIGERANT AND

OIL WILL BE RELEASED THAT CAN BE IGNITED

BY AN EXTERNAL HEAT SOURCE (OPEN

FLAME, HEATER, ETC.). ALSO, IF THERE IS AIR

IN THE SYSTEM WHEN THIS HAPPENS, A

SPARK AT THE COMPRESSOR SHELL COULD

IGNITE THE REFRIGERANT AND OIL MIXTURE.

NOTE: If compressor has a permanent split

capacitor (PSC) motor, running capacitor should be

tested first.

1. Disconnect dehumidifier from electrical supply.

2. Remove leads from compressor terminals.

3. Check for grounded windings by testing continuity

from each terminal to any copper tubing connected

directly to compressor. If continuity is indicated,

motor windings are grounded and compressor will

have to be replaced.

4. Check for open windings by checking continuity

from Start-to-Run terminals. If no continuity is

found, a winding is open and compressor must be

replaced.

Possible Causes of Compressor Overloading or

Overheating

1. Shorted winding. Recheck Start and Run windings.

2. Low voltage. With dehumidifier disconnected,

check voltage at electrical outlet. Voltage should be

of 115 VAC,+/- 10%.

3. Plug in dehumidifier and check voltage. If voltage is

not within +/- 10% of 115 VAC, compressor break

down or overheating may occur. Excessive voltage

drop during start-up or while running may be cause

of motor overload opening.

4. Defective run capacitor (if supplied). If compressor

will not start (or starts slowly), or compressor runs

but draws high current, test capacitor.

5. Dirty evaporator and/or condenser.

6. Insufficient air passing over condenser.

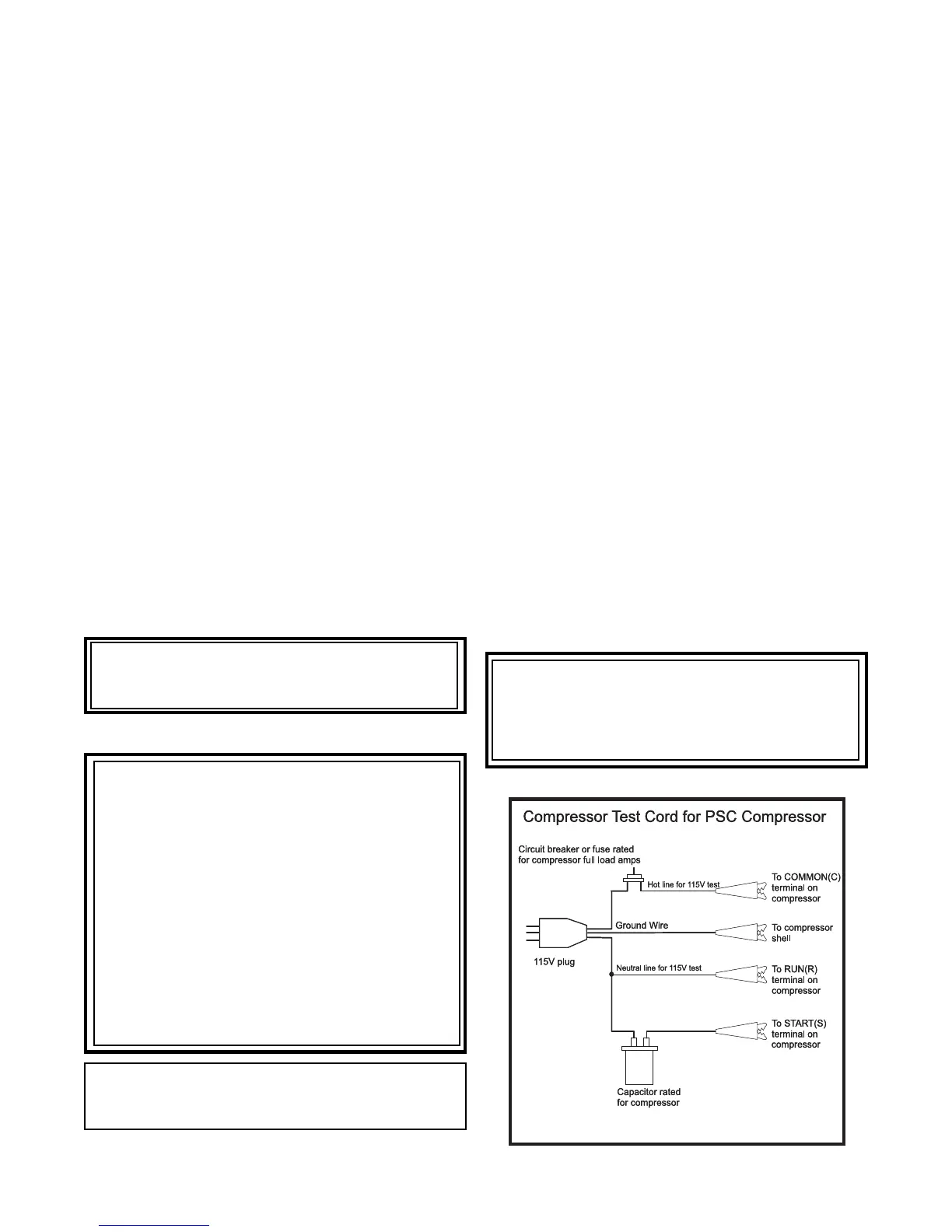

The compressor can also be operated on a test cord when

connected as illustrated below.

CAUTION: If compressor is a permanent split

capacitor type, use only a known good

electrolytic capacitor, rated for compressor

being tested. This running capacitor must be in

circuit while compressor is running.

Compressor Test Cord for PSC Compressor

Loading...

Loading...