12

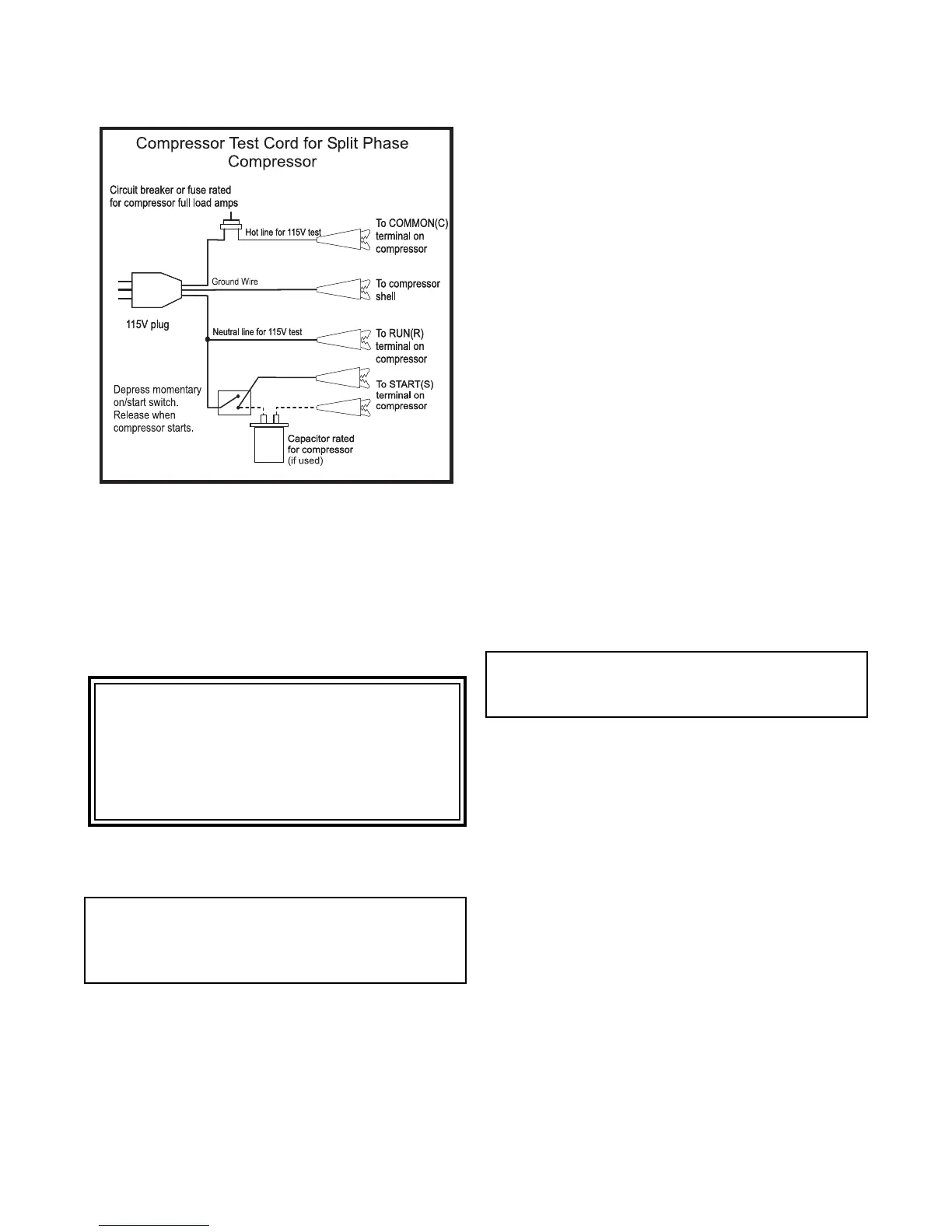

Compressor Test Cord for Split Phase

Compressor

Running Capacitors

Running capacitors are used on some compressor motors

to increase the efficiency of the motor by improving the

power factor.

Always replace running capacitors with capacitors of like

type and mF (microfarad) rating. Pay particular attention to

the voltage rating.

To Test Capacitor

WARNING: AN INTERNALLY SHORTED

CAPACITOR MAY EXPLODE IF ENERGIZED

DIRECTLY WITH LINE VOLTAGE. CHECK ONLY

WITH AN OHMMETER OR CAPACITOR TESTER.

AFTER TESTING, ALWAYS DISCHARGE

CAPACITOR WITH A 20,000W (OHM), 2 WATT

RESISTOR PLACED ACROSS THE TERMINALS.

1. Disconnect dehumidifier from electrical supply.

2. Remove wrapper.

3. Discharge capacitor.

NOTE: Best method of discharging capacitor is with

insulated copper wire in series with a 20,000 ohm,

2 watt resistor. Place this high resistance jumper

across capacitor terminals.

4. Disconnect capacitor wiring.

5. Connect ohmmeter across terminals of capacitor to

be checked:

a. If capacitor is good, needle should jump toward

zero ohms and quickly drop back to infinity.

b. If needle does not move, capacitor is open.

c. If needle reads constant value at near zero

ohms, capacitor is shorted.

d. If needle jumps toward zero and falls back to

constant high resistance value (not infinity),

capacitor has high resistance leak.

e. Check for ground from each terminal of capacitor

to bare metal of capacitor case. Resistance

should be infinite. If resistance is less than

infinite, capacitor is grounded.

Replace capacitor if it is open, shorted, grounded or has

a high resistance leak.

Compressor Overload Protector

An overload protector is attached to the compressor to

detect excessive heat or a current overload. If the overload

is actuated, it will shut off the current to the compressor

and automatically reset itself after a short cool down

period. The compressor will attempt to start after the cool

down period.

The overload is located under the terminal cover. To gain

access to the overload, disconnect the dehumidifier from

the electrical supply and remove the terminal cover.

To Test Overload

1. Disconnect dehumidifier from electrical supply.

2. Remove wrapper.

3. Remove terminal cover.

4. Disconnect all wiring to overload and check across

overload terminals with ohmmeter. (Overload

should be at room temperature when checked.)

Zero ohms (0W) should be indicated.

NOTE: Always replace terminal cover and gasket

to protect overload and compressor terminals from

moisture and corrosion.

To Test Relay (Split Phase Compressor)

1. Disconnect dehumidifier from electrical supply.

2. Remove relay and overload cover from

compressor.

3. Disconnect wire to relay and remove relay from

compressor terminals (pull straight off).

4. Check continuity of relay coil (refer to wiring

diagram for proper terminals to check across). If

relay coil checks OK, use compressor test cord to

test compressor.

5. If PTC relay is used, check resistance between L1

and Start winding. Resistance should be no more

than 4 ohms at room temperature.

To Replace Relay (Split Phase Compressor)

1. Disconnect humidifier from electrical supply.

2. Remove wrapper.

3. Remove relay cover from relay and overload.

4. Remove wire from relay and pull straight off.

5. Reverse procedures to reassemble.

Loading...

Loading...