38

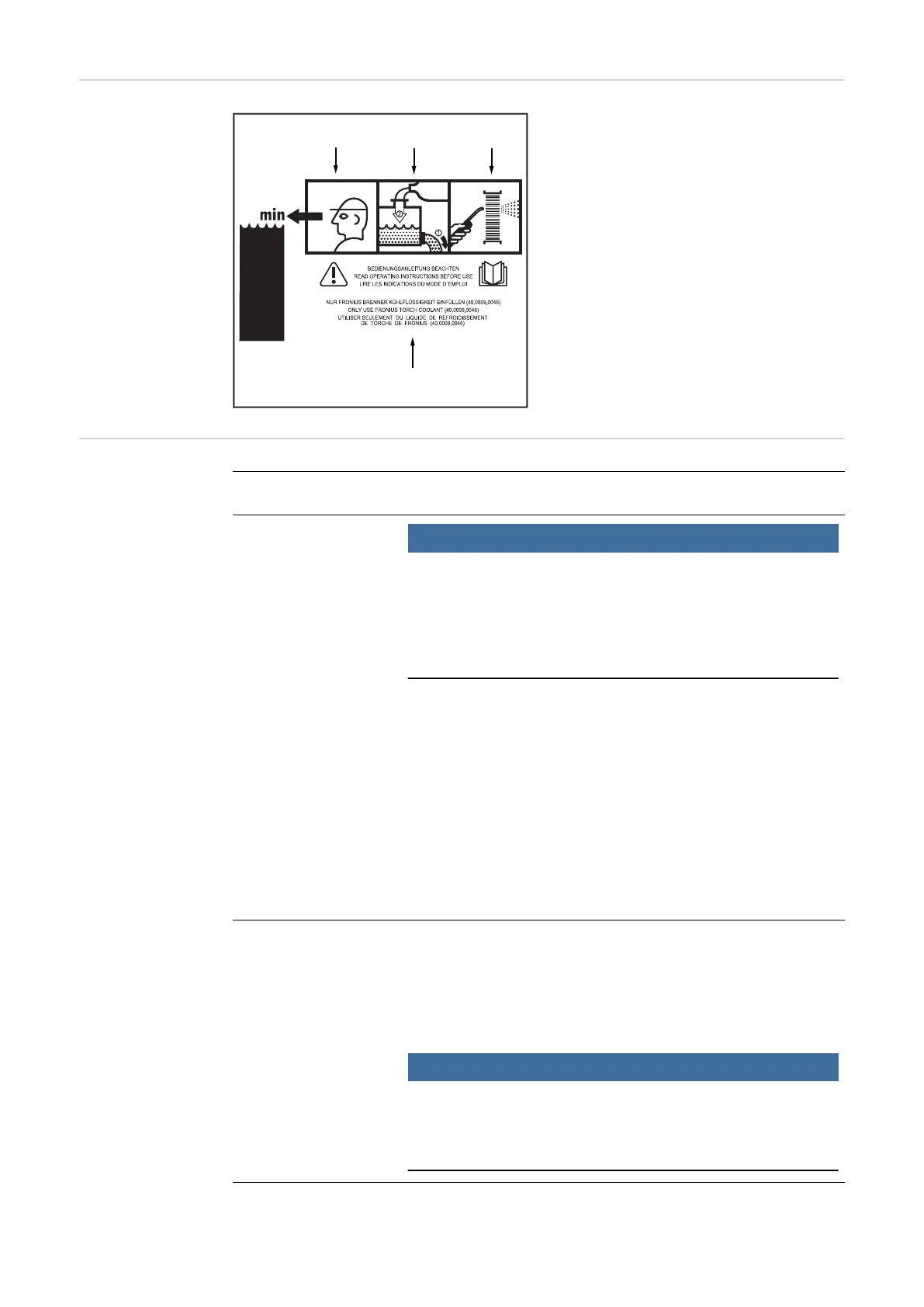

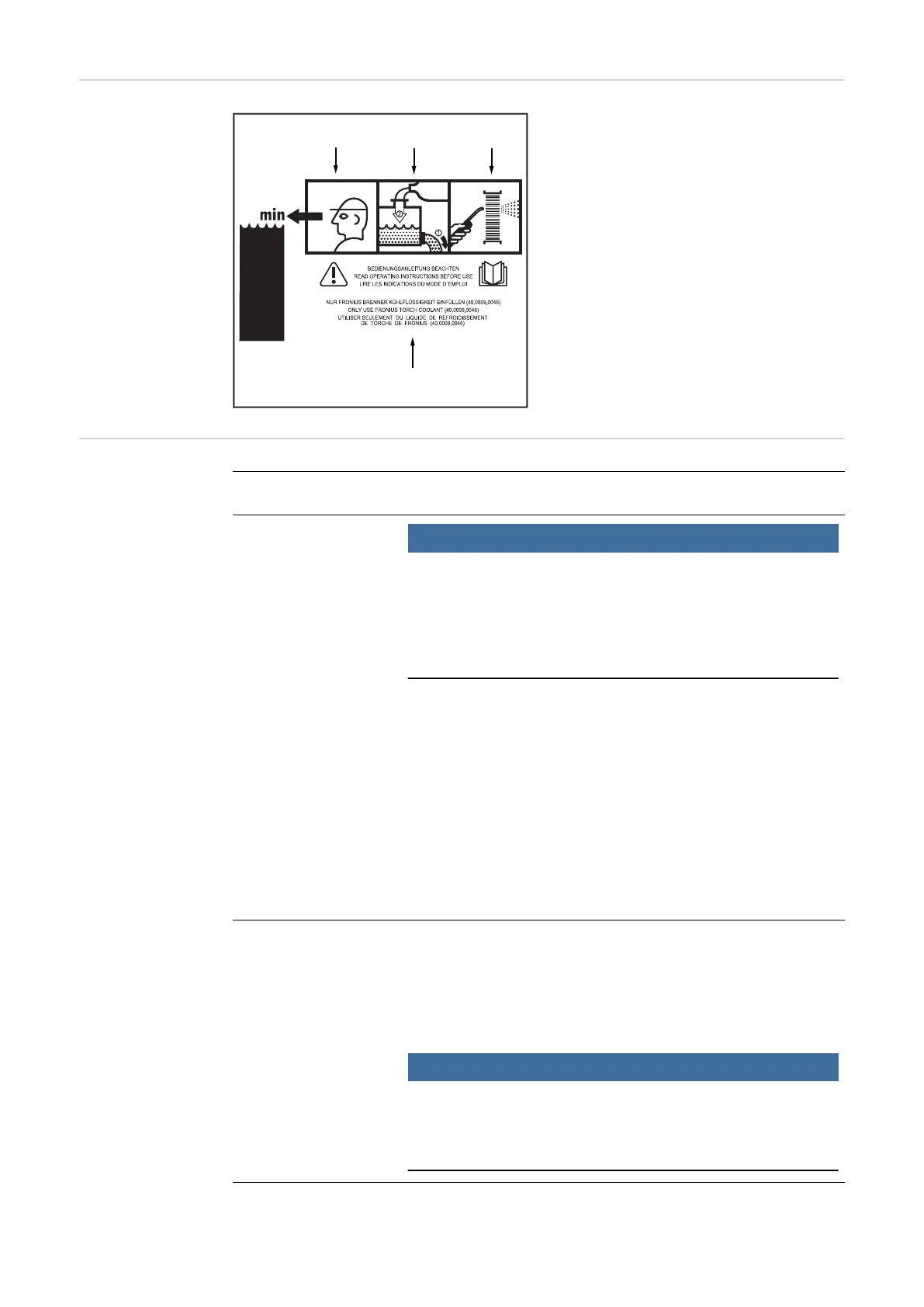

Symbols for care

and maintenance

of the cooling unit

(1) Check coolant level

(2) Change the coolant

(3) Gas purge the cooler

(4) Read operating instructions

The relevant maintenance intervals and

work are described in detail in the following

pages.

Maintenance in-

tervals, mainte-

nance work

(1)

(2)

(3)

(4)

Maintenance in-

terval

Maintenance work

At every start-up

NOTE!

If water-cooled system components are operated without

coolant, this will normally result in the failure of the system

components.

Fronius shall not be liable for any damage resulting from such

action. In addition, no warranty claims will be entertained.

- Ensure that all the hosepacks, the welding torch and the

ground earth connection are undamaged

- Check that there is an all-round clearance of 0.5 m (1 ft.

7.69 in.) around the device to ensure that cooling air can

flow in and out freely

- Check the screw connections between all system compo-

nents for tightness

- Check all the coolant connections of the welding system for

tightness

- Monitor the coolant return flow in the coolant container

- If no coolant is returning to the container, identify and

remedy the cause

Every week - Check coolant level. If the coolant level is below the "min"

mark, top up with coolant

- Check the purity of the coolant. Change the coolant if nec-

essary

NOTE!

Use only original Fronius coolant (Cooling Liquid FCL 10/

20 or torch coolant) when filling the cooling unit.

Other coolants are not recommended for electrical conductivity

and material compatibility reasons.

Loading...

Loading...