Do you have a question about the Fronius TransPocket 1500 RC HD and is the answer not in the manual?

Welcome note and guidance on using the manual.

Defines Danger, Warning, and Caution levels for risks.

Includes notes on welding results and important hints.

Equipment safety compliance and user responsibilities.

Machine must only be used for pre-heating welding wires in TIG hot-wire welding.

Specifies operating temperature, humidity, and air quality requirements.

Owner must ensure personnel are qualified and trained.

Personnel must adhere to safety rules and manual instructions.

Lists hazards and required protective measures for users.

Recommends ear protection and keeping others away from the welding area.

Welding fumes are harmful and may cause health issues.

Flying sparks can cause fires and explosions; avoid combustible materials.

Sparks can enter surrounding areas; avoid welding in potentially explosive locations.

Electric shock is fatal; do not touch live parts.

Ensures proper grounding and using PE conductor outlets.

Ignored instructions can cause fires, overheating, and damage.

Owner must prevent electromagnetic interference affecting equipment and health.

Lists ancillary measures like mains supply filtering and cable arrangement.

Keep clear of moving parts like fans, rollers, and wire-spools.

Allow hot components to cool; observe fire/explosion regulations.

Cylinders contain pressurized gas, can explode if damaged; handle with care.

Machine must be placed firmly on an even floor; observe fire/explosion rules.

Operate only with fully functional protective features; never bypass them.

Use original spare parts and avoid unauthorized modifications.

Ordering spare parts requires exact designation and serial number.

Obligation for safety inspection every 12 months; calibration recommended.

Explains CE and CSA marks of conformity.

Copyright information for the manual.

Explains the resonance inverter principle used in the power source.

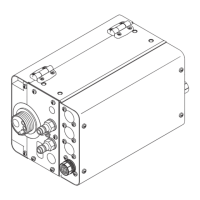

Describes the robust construction and portability of the machine.

Machine is for pre-heating welding wires in TIG hot-wire welding with constant output voltage.

Illustrates an example application with a robot and other equipment.

Warning about operating incorrectly before reading manual.

Identifies front panel controls and connection sockets.

Warning about risks during installation and pre-service checks.

Reinforces that the source is only for pre-heating welding wires in TIG hot-wire welding.

Details IP23 protection and placement requirements for ventilation.

Warning about voltage, plugs, leads, and fuse protection.

Warning about incorrect operation and pre-use checks.

Instructions for connecting the pre-heating unit cables.

How to set output current using the adjusting dial.

How to set output current using an external analogue signal.

Warning about electric shock before maintenance; unplugging required.

Regular cleaning, safety inspections, and checking components.

Details on removing/soldering resistor R11 for analogue signal function.

Machine suitability for generators and voltage tolerance.

Warning about mains plugs, leads, and fuse protection.

Lists specifications like mains voltage, current, power, and cooling.

Warning about electric shock during troubleshooting; unplugging required.

Lists common issues like "No output current" and their causes/remedies.

Addresses issues like tripped fuses and loud bangs with causes/remedies.

Provides the detailed electrical schematic of the power source.

Loading...

Loading...