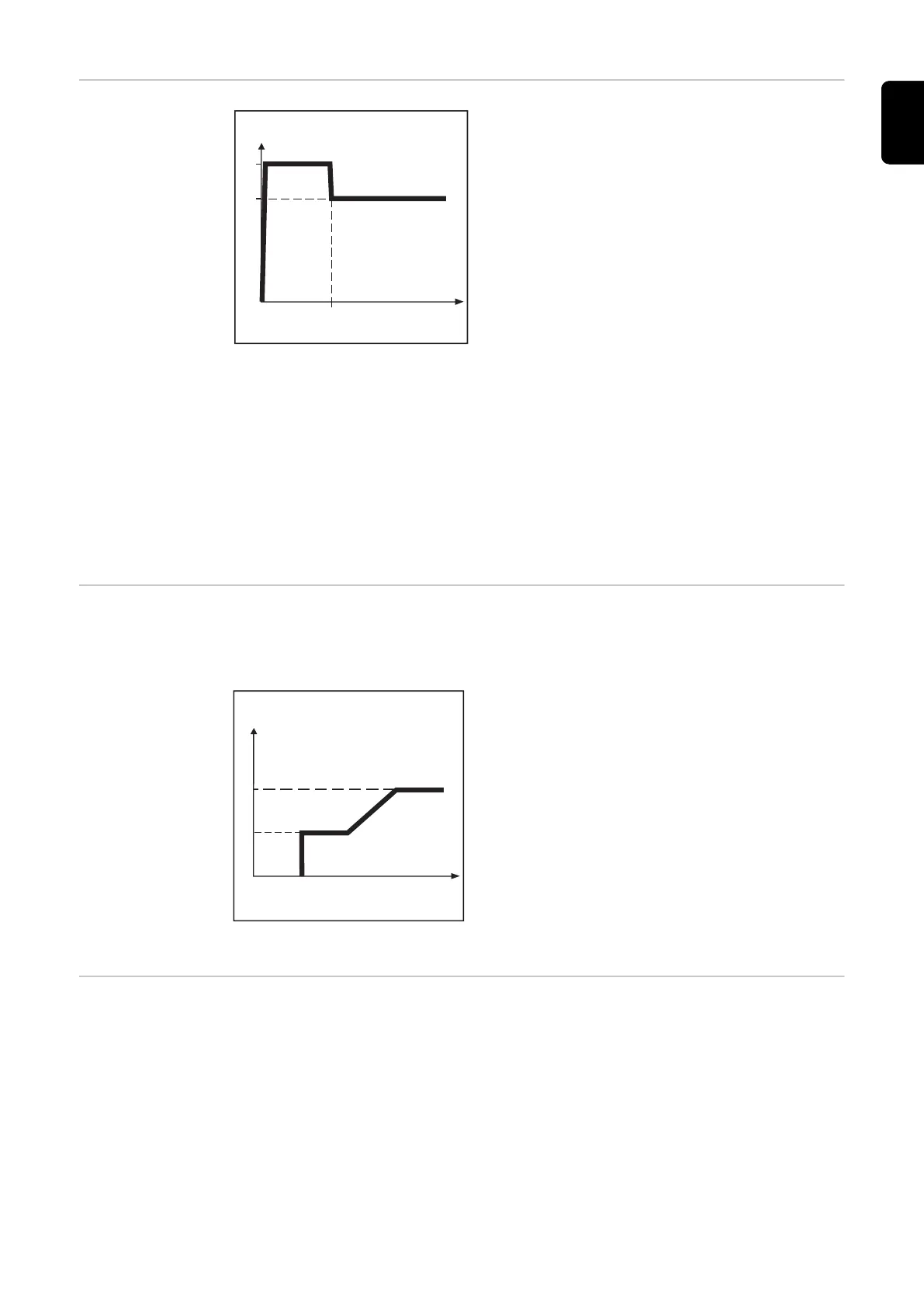

HotStart function

(used with rutile

and Cel pro-

cesses)

Example of HotStart function

Benefits:

- Improved ignition properties, even

when using electrodes with poor igni-

tion properties

- Better fusion of the base material dur-

ing the start-up phase, meaning fewer

cold-shut defects

- Largely prevents slag inclusions

Mode of operation:

The welding current is raised to a specific value for 1.5 seconds. This value is around

30% higher than the set welding current

Example: 90 A was set on the adjuster.

The HotStart current is 90 A + 30% = 117 A

IMPORTANT! If the welding current is set to 192 A or higher, the HotStart current is lim-

ited to 250 A.

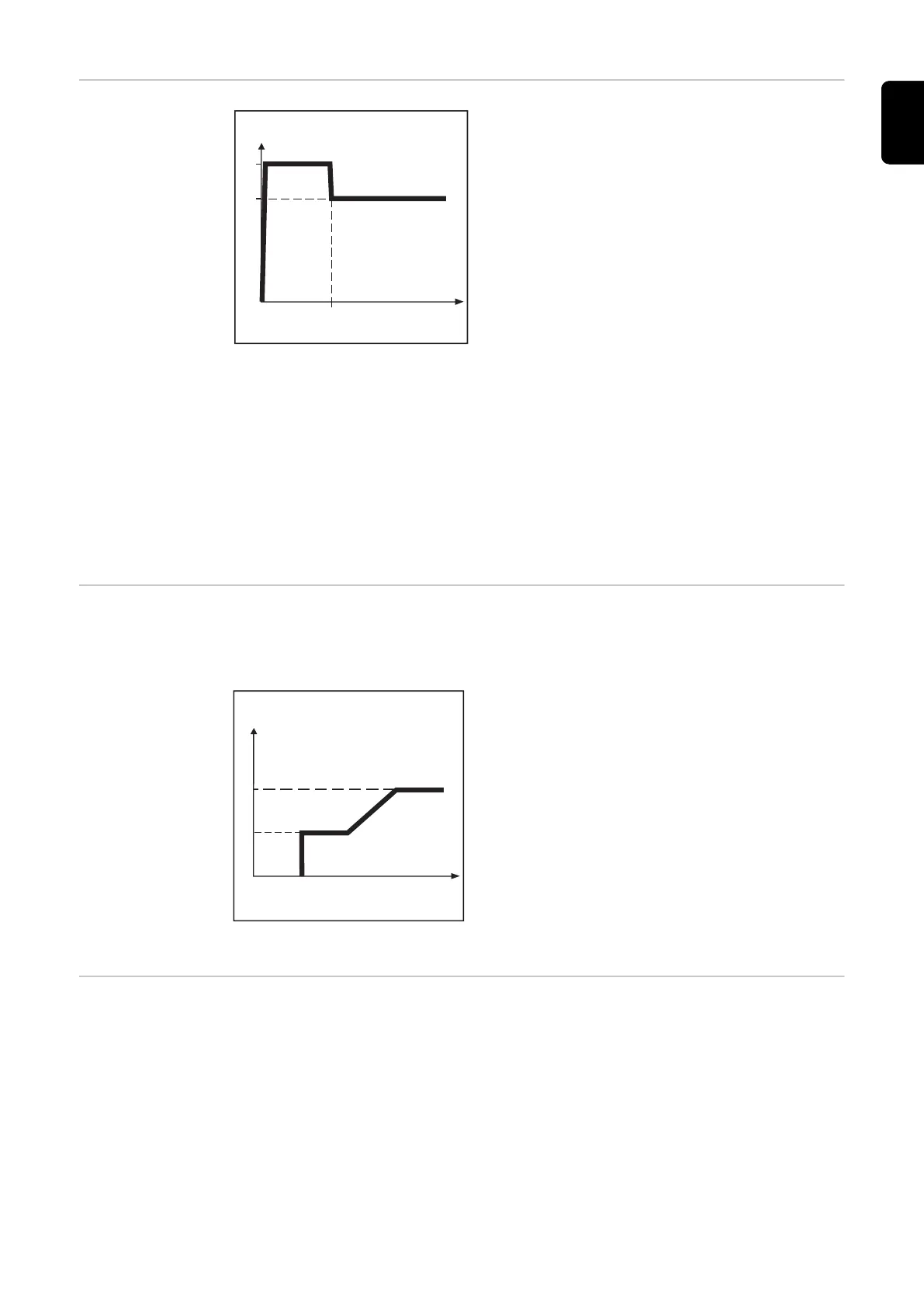

SoftStart function

(used with basic

process)

The SoftStart function is intended for basic electrodes. Ignition takes place at a low weld-

ing current. Once the arc is stable, the welding current continues to rise until it reaches

the welding current command value.

Example of SoftStart function

Benefits:

- Improved ignition properties for elec-

trodes that ignite at low welding cur-

rents

- Largely prevents slag inclusions

- Reduces welding spatter

Anti-stick func-

tion

As the arc becomes shorter, the welding voltage may drop so far that the rod electrode

will tend to stick.

The anti-stick function prevents the electrode from burning out. If the rod electrode

begins to stick, the power source switches the welding current off after 1 second. After

the rod electrode has been lifted off the workpiece, the welding operation can be contin-

ued without difficulty.

25

EN

Loading...

Loading...