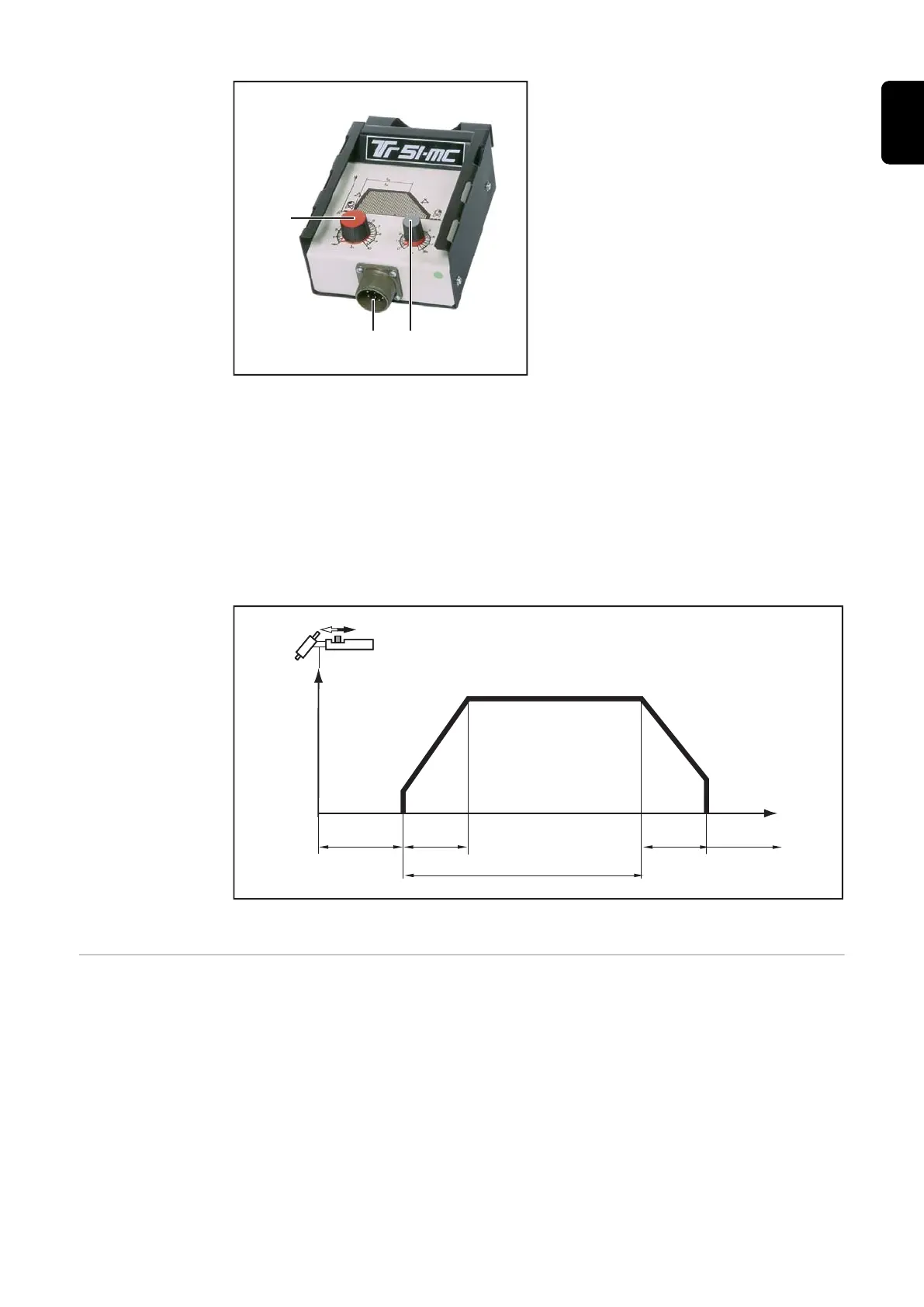

TIG spot welding remote control TR 51mc

(1) Controller for spot welding current

I

1

(2) Remote control connection socket

(3) Spot welding time controller SPt

(0.1 - 8 s)

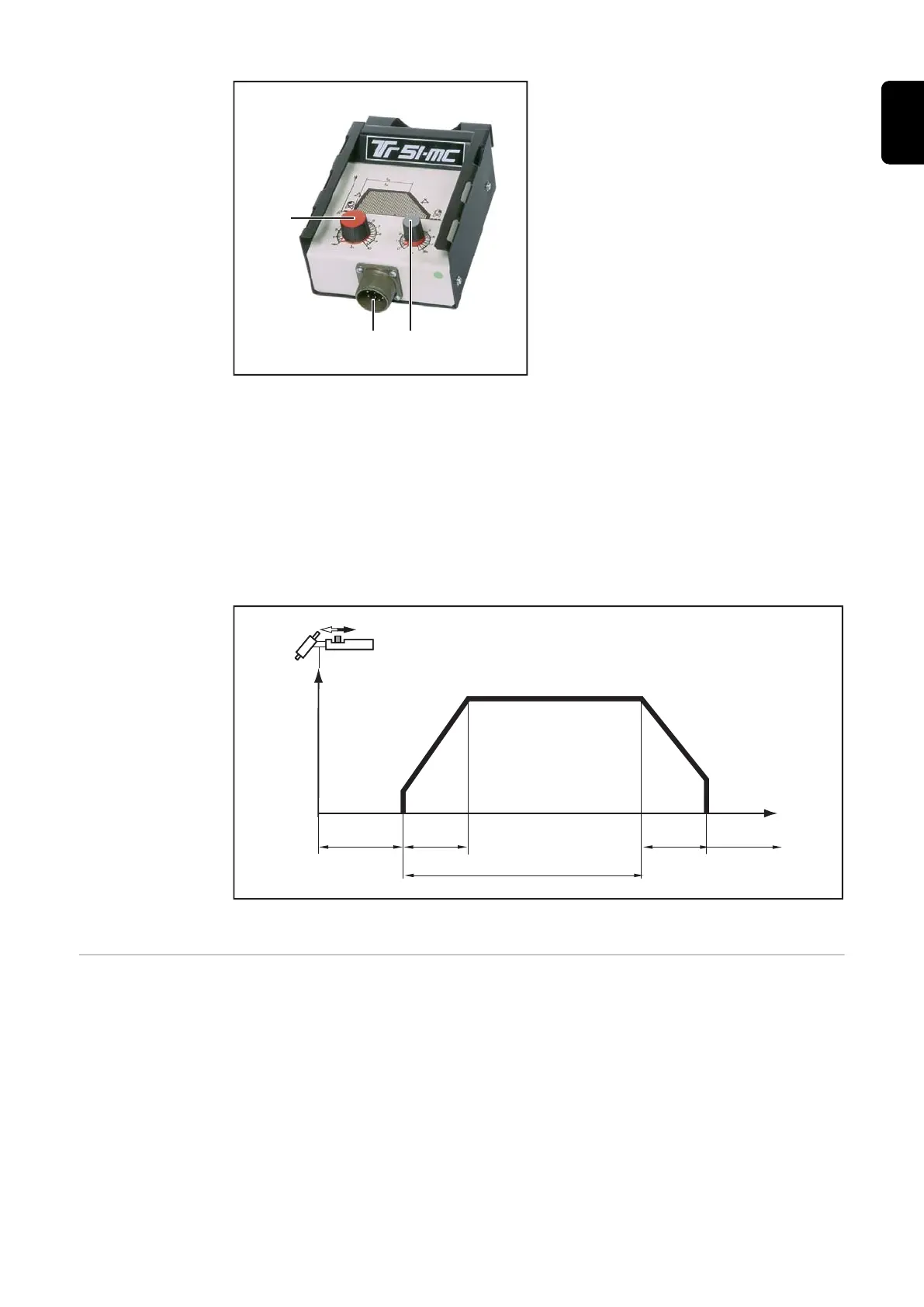

Functional sequence:

- 2-step mode indicator lights up as soon as the remote control is connected (auto-

matic switching)

- Set current lowering time on the power source

- Use special spot welding nozzle (sits insulated on the cone)

- Mount tungsten electrode set back from nozzle edge (approx. 2-3 mm (0.10 in.)

depending on spot size)

- Place welding torch on the sheet and apply slight pressure to the parent material

- Initiate spot welding process (avoid air gap)

Spot welding

Remote control

TP MC / TP MC-

CEL

The TP MC / TP MC-Cel remote control is particularly suitable for MMA and TIG DC

welding.

53

EN-US

Loading...

Loading...