8

OVERTEMPERATURE INDICATOR lights up

- If the unit is overloaded

- If the temperature has been reached on the primary heat

sink, on the secondary heat sink (see Fig.1)

MARK LED INDICATOR

- lights up when the monitoring function is activated

- this LED indicates that the AC voltage in the welding current

circuit does not exceed 48 V

TIG TORCH CONNECTION

- for connecting the GAS + CURRENT supply for the welding

torch at gas cooled units

- for connecting the WATER + CURRENT supply for the

welding torch at water cooled units

SOCKET with bayonet coupling

- as the earth cable connection point with TIG welding;

- as the connection either for the manual electrode cable or

the earth cable with manual electrode welding, depending

on the type of electrode used.

SOCKET with bayonet coupling

- as the connection either for the manual electrode cable or

the earth cable with manual electrode welding, depending

on the type of electrode used.

The following parameters are laid down

- Gas pre-flow time ....................................... 0,4 sec.

- Start arc: 36 % of I

H

in DC mode ............... 36% of I

H

50 % of I

H

in AC mode ................................ 50% of I

H

- Up-slope ..................................................... 1,0 sec.

- Gas post-flow time ...................................... 5-15 sec.

- Frequency .................................................. 60 Hz

All parameters can be changed individually, via a program menu.

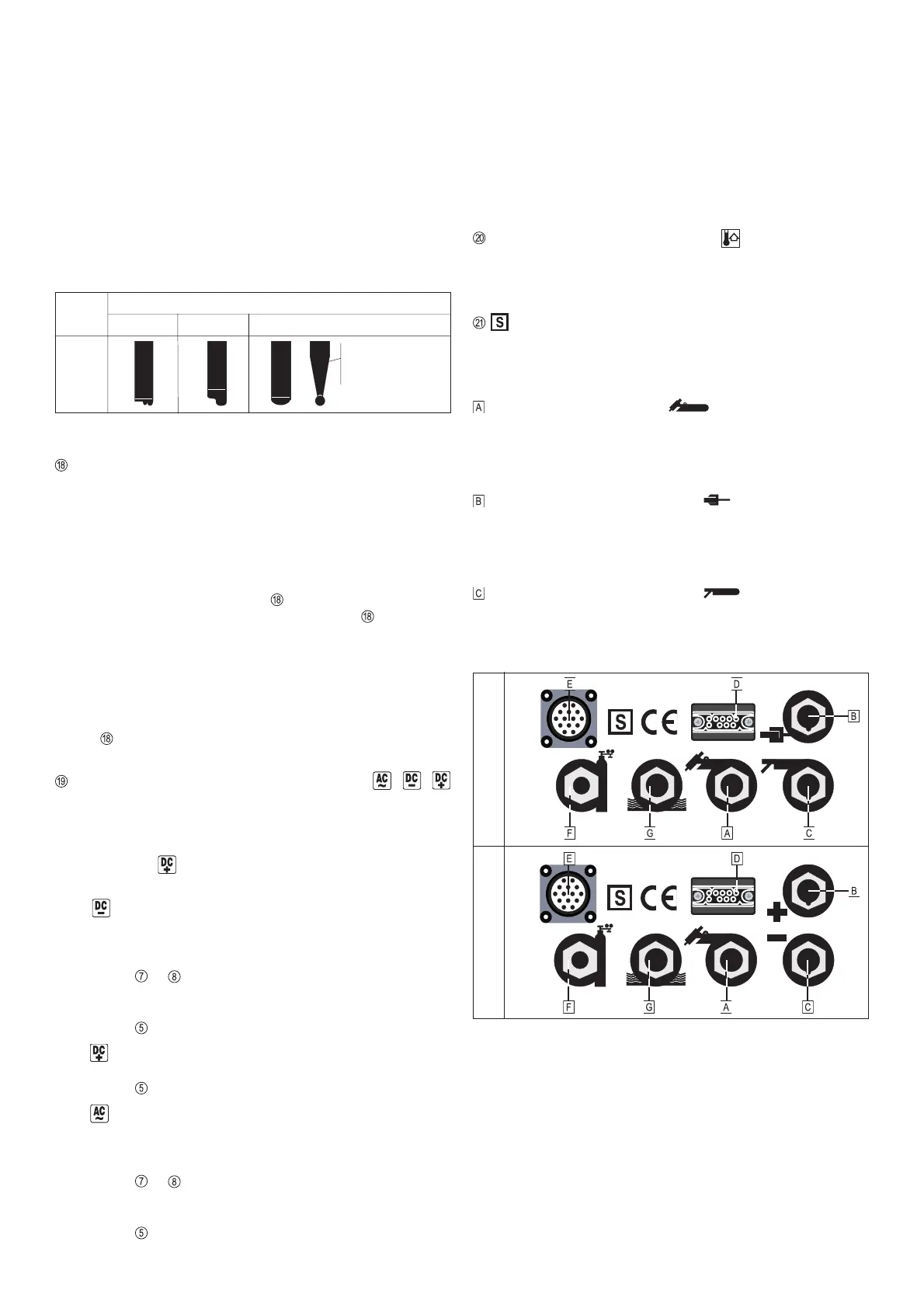

Type of

current

Current load

too low

too high

a) b) c)

AC

~

correct

good for

root passes and

thin workpieces

Fig.7 Shapes of formed on tungsten electrodes subjected to different loads in

the AC range

Examples of settings:

a) Balance dial is in position "0"

Neutral setting

b) Balance dial is in position "+5"

The positive half-waves are longer than the negative ones =

long cleaning phase but reduced penetration depth; in-

creased load on tungsten electrode - cap formed on elec-

trode tip is too large (Fig.7b)

c) Balance dial is in position "-5"

The negative half-waves are longer than the positive ones =

long penetration phase but reduced cleaning effect; tungs-

ten electrode is underloaded - no cap formed on electrode

tip (Fig. 7a)

ADJUSTMENT DIAL FOR DIAMETER OF

TUNGSTEN ELECTRODE (von 0 - 4,0mm)

a) AC-operation: (only MW 2600 / 2600 CEL / 3000)

For automatic formation of a spherical tip to the tungsten

electrode. Before starting to weld, briefly push the torch

trigger forward and then initiate the welding operation. A

spherical tip is then formed on the - pointed or blunt - tung-

sten electrode, as determined by the electrode-diameter

value set beforehand on dial .

- If the torch trigger is not pushed forward, dial can be used

to set the ignition current for the diameter of tungsten

electrode in question.

b) DC-operation:

- Is used to set the ignition current for the diameter of tung-

sten electrode in question.

When the machine is in the “Electrode" modes, adjustment

dial is inactive.

SELECTOR BUTTON for TYPE OF CURRENT / /

(only on MW 2600 / 2600 CEL / 3000)

This is used for selecting the type of current required, and for

reversing the polarity with both TIG and ROD ELECTRODE

MANUAL WELDING.

At TIG mode

is locked.

Functional description:

1.

: Direct current ð TIG welding of unalloyed, low and high

alloy steels, Sn or Cu bronzes, copper etc.

a) TIG mode

- Minus pole is on the tungsten electrode

- Led

or lights up

b) MANUAL ELECTRODE mode

- Minus pole is on the rod electrode

- Led

lights up

2. : Direct current ð Manual electrode welding

- The plus pole is on the rod electrode

- Led

lights up

3.

: Alternating current ð TIG welding of aluminium and

its alloys, aluminium-bronze etc.

a) TIG mode

- Alternating current is on the tungsten electrode

- Led

or lights up

b) MANUAL ELECTRODE mode

- Alternating current is on the rod electrode

- Led

lights up

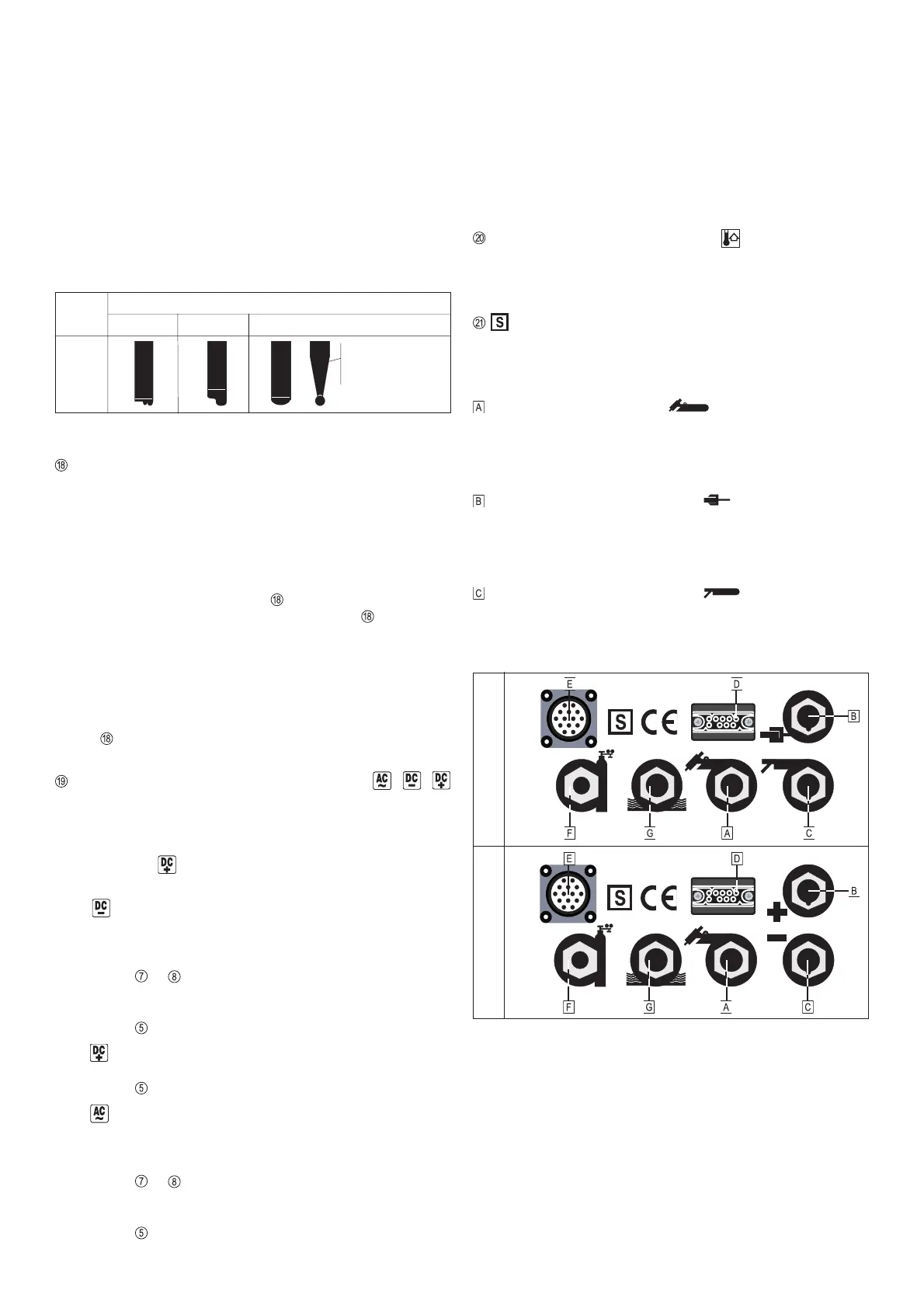

Fig.8 Design with central welding torch connection GWZ: Connection points on

front of machine

TRANSTIG MAGIC WAVE

Loading...

Loading...