7

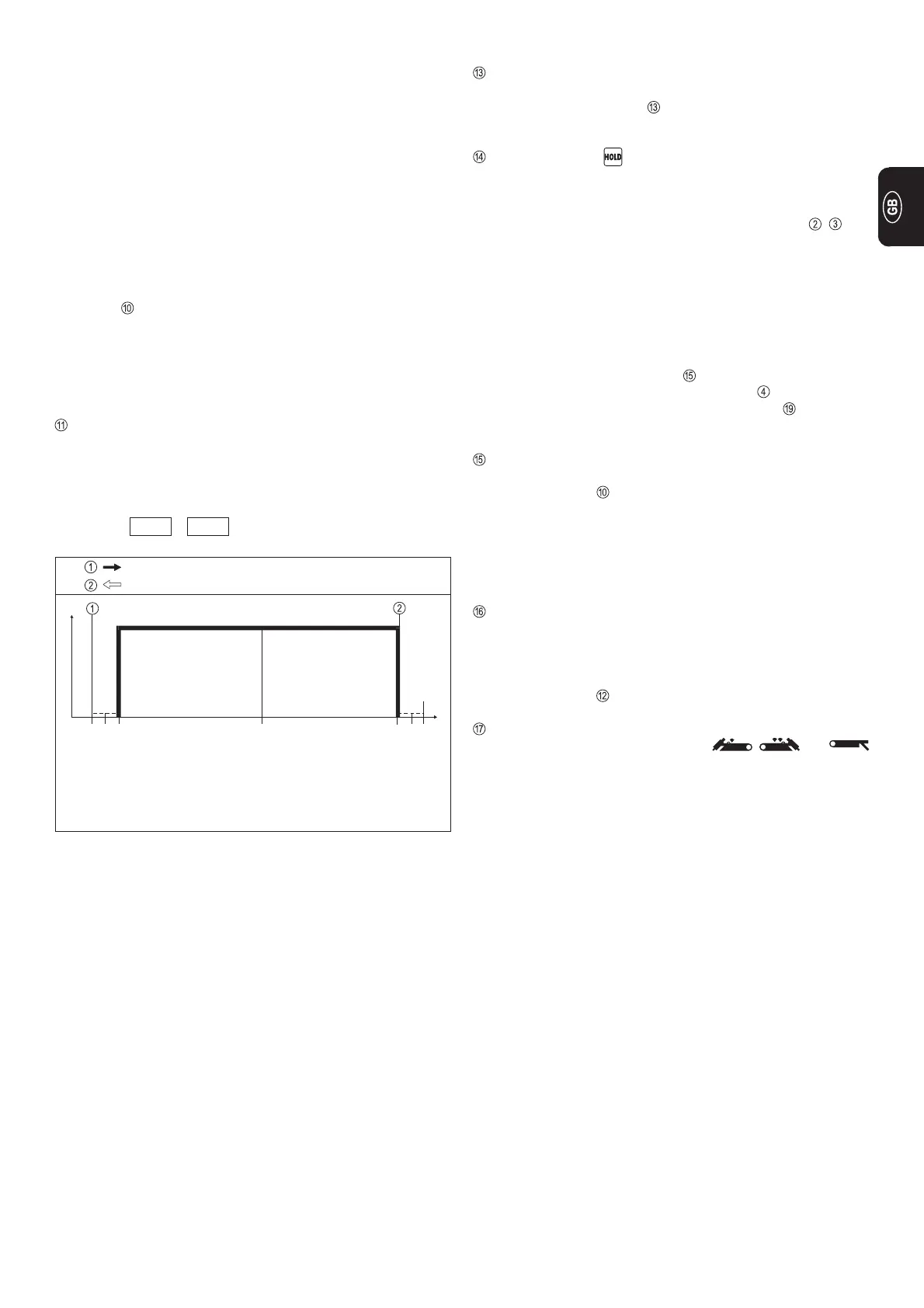

Special 2-step mode (Fig.6a)

- is activated from TIG torch trigger

- is mainly used for tack welding

- In the "PRESETTINGS LEVEL ---" program-level (see "Wor-

king with the program-levels"), parameter TIG, the setting

for StS must be set to "ON"

Functional sequence:

1. Pull back and hold the torch trigger

- Gas pre-flow time elapses

- Arc ignites at the pre-set value for start-arc current I

S

(with

HF ignition: HF cuts out automatically after ignition)

- Welding current rises, without upslope, to the welding-

current value I

H

- LED lights up

2. Release the torch trigger

- Arc goes out (without the current being lowered)

- The internally pre-set gas post-flow time elapses

When the remote-control pedal unit TR 52mc is used, the

machine automatically switches over to 2-step mode.

DOWNSLOPE or current drop time:

- Continuously adjustable current-lowering rate from main

current to crater-fill current I

E

Adjusting range: from 0.1 to 20 seconds

- When the downslope potentiometer is actuated, the pre-set

value is indicated for 3 seconds

e.g.: d S L 1.0

Start of cycle

Gas pre-flow time

End of welding

Gas post-flow time

Pull back and hold the torch trigger

Release the torch trigger

Arc ignition

Welding with pre-set

main current I

H

Fig. 6a Functional sequence in special2-step mode

I

H

I

t

LED INDICATOR FOR TIG PULSED-ARC WELDING

- As soon as the TR 50mc TIG remote-control pulsing unit is

connected up, the LED

(see "TR 50mc TIG remote-control

pulsing unit") starts to flash

LED INDICATOR

- enables retrospective verification of the welding parameters

- lights up after actual values have been stored (end of

process)

- average value is indicated on the digital displays , (the

values measured for welding current and voltage before the

end of a welding operation)

- function is not available when a remote-control pedal unit is

being used, or when the arc is pulsed at 20Hz or below

Possible ways of clearing the HOLD function

- Actuate the torch trigger during the weld-off period

- Switch the machine off and then back on again

- Adjust the main-current dial during the weld-off period

- Switch over the function selector button

- Switch over the current-type selector button

- Every time a new welding operation is started

MAIN-CURRENT DIAL I

H

= welding current

- Continuous adjustment throughout a 3-260/300 A range

- LED indicator lights up (only in "Electrode" mode)

- Digital ammeter indicates the command value for the cur-

rent, already in open circuit, and then switches over to

displaying the actual value

Command value ð desired welding current

Actual value ð actual welding current

CRATER-FILL CURRENT I

E

- Only possible in 4-step mode

- Set as a percentage of the main current

- Operator lowers the welding current down to the crater-fill

current by pressing the torch trigger

- LED indicator lights up

BALANCE DIAL (only MW 2600 / 2600 CEL / 3000)

- Only functions in the AC range in , and

modes

- Positive and negative half-waves can be changed

- For better adaptation to the welding problem in question

(optimisation of cleaning and penetration behaviour)

- For optimised electrode cap-shaping (Fig.7c)

Loading...

Loading...