6

Push forward and hold the torch trigger

Release the torch trigger

Fig. 5c Functional sequence in special 4-step mode - Variant IV

Pull back and release the torch trigger

I

S

I

H

I

E

I

t

Pull back and hold the torch trigger

Release the torch trigger

I

H

Start of cycle

Gas pre-flow time

Current rises via

upslope

Current drops via

downslope

Gas post-flow time

End of welding

Crater-fill current

Arc ignites with start-arc

current I

S

Welding with pre-set

main current I

H

Current rises via

upslope

Welding with pre-set

main current I

H

Start of cycle

Gas pre-flow time

Current rises via upslope

Current drops via

downslope

Gas post-flow time

End of welding

Crater-fill

current

Pull back and hold the torch trigger

Release the torch trigger

Release the torch trigger

Arc ignites with start-arc

current I

S

Welding with pre-set

main current I

H

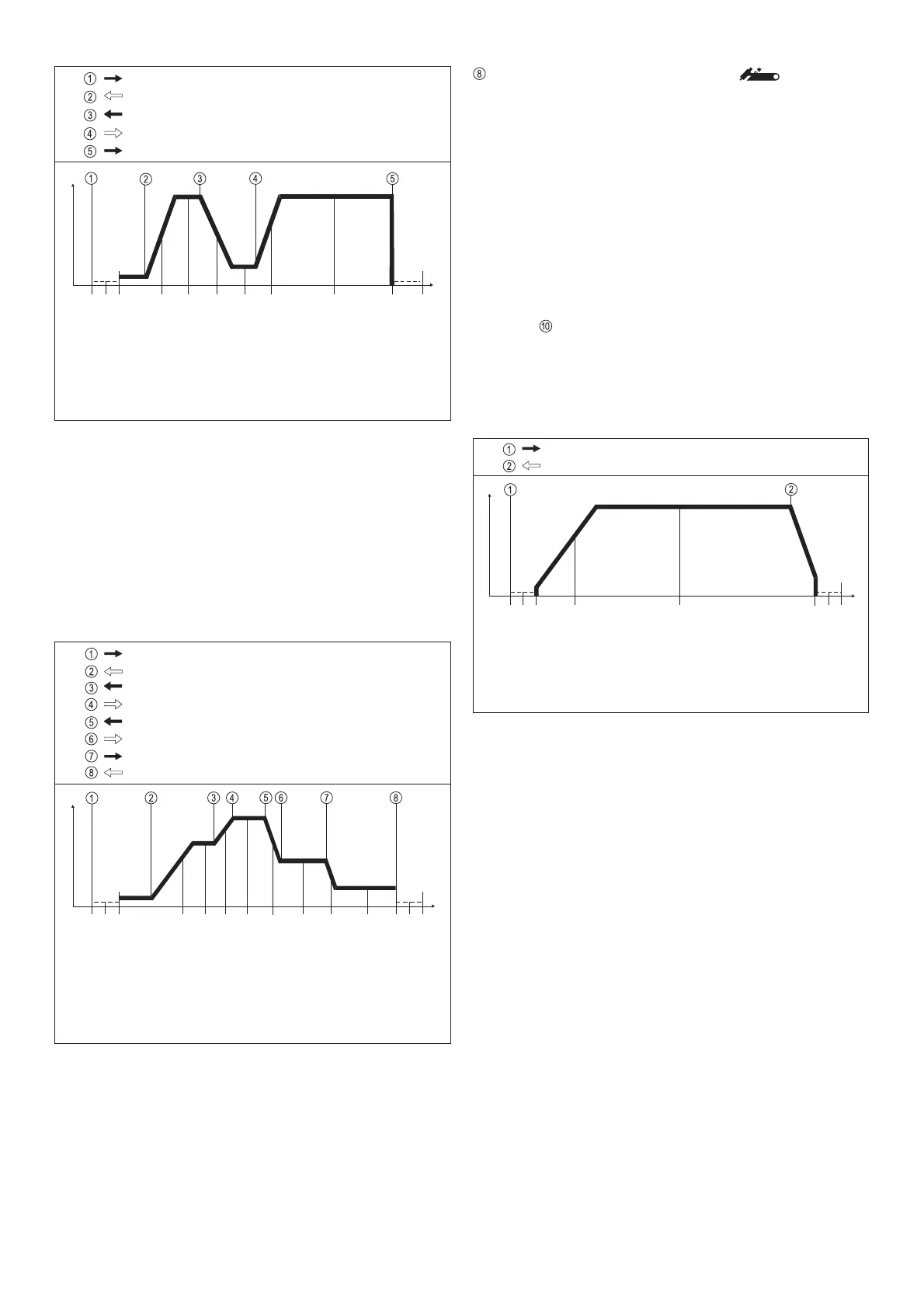

Fig. 5d Functional sequence in special 4-step mode - Variant V

Push forward and hold the torch trigger

I

S

I

H

I

E

I

t

Current-rise when torch

trigger is pushed forward

Current-drop when torch

trigger is pushed forward

Welding with decreased

main current I

H

Push forward and hold the torch trigger

Release the torch trigger

Pull back and hold the torch trigger

Release the torch trigger

Welding with increased

main current I

H

Variant V (Fig. 5d) allows the welder to raise and lower the welding

current without an Up/Down torch.

The longer the torch-trigger rocker switch is pushed forward

during welding, the more the welding current is increased (up to

maximum).

After the welder releases the torch trigger, the welding current

remains constant. The longer the torch trigger is pushed forward

once again, the further the welding current is reduced.

Diagram showing intermediate lowering

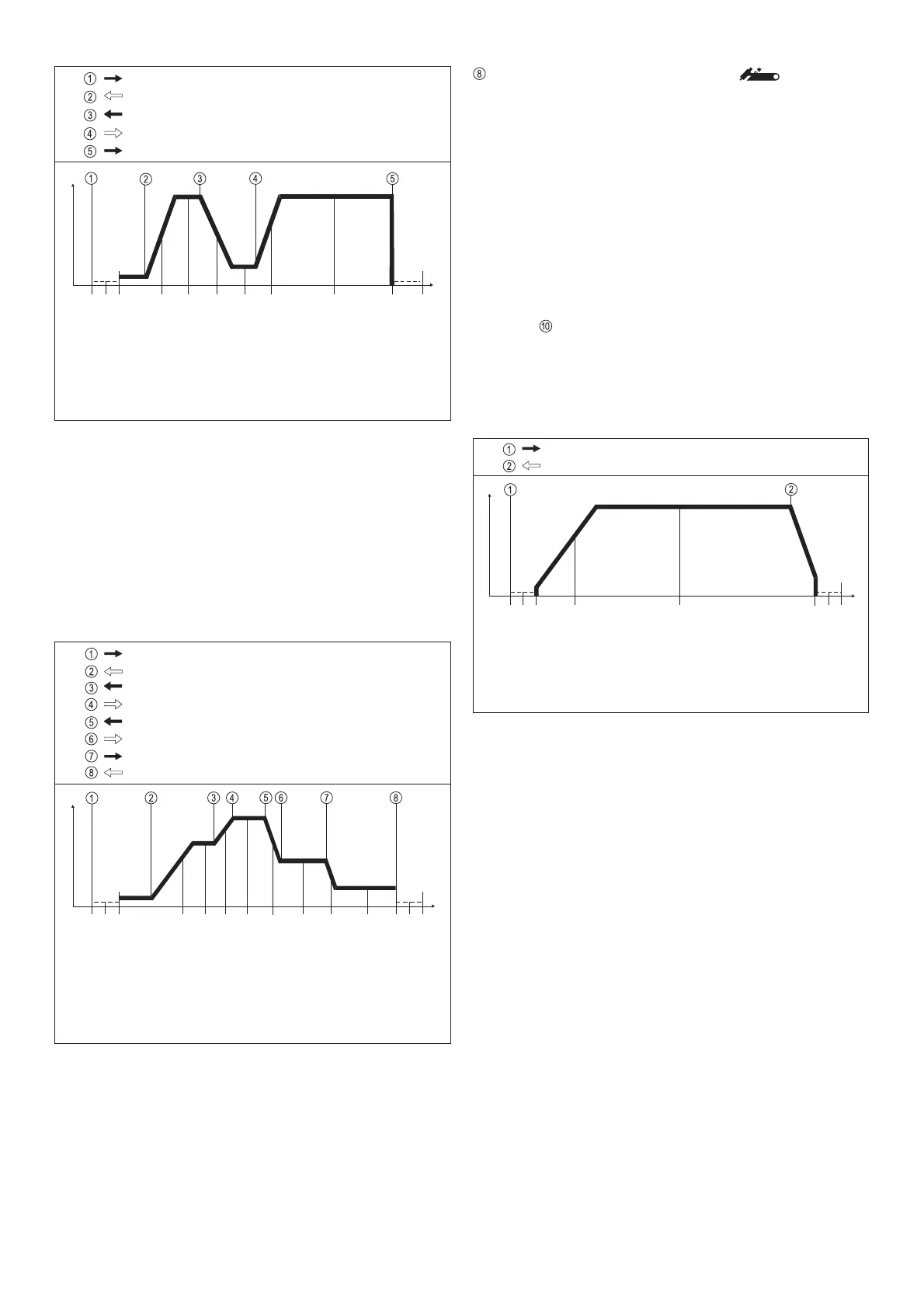

LED INDICATOR FOR 2-STEP MODE

2-step mode (Fig.6)

- is activated from TIG torch trigger

- is mainly used for tack welding

- In the "PRESETTINGS LEVEL ---" program-level, parame-

ter TIG, the setting for StS must be set to "OFF"

Functional sequence:

1. Pull back and hold the torch trigger

- Gas pre-flow time elapses

- Arc ignites at the pre-set value for start-arc current I

S

(with HF

ignition: HF cuts out automatically after ignition)

- After ignition, the welding current rises via the internally pre-

set upslope to the welding-current value I

H

- LED lights up

2. Release the torch trigger

- Arc goes out (with or without the current being lowered)

- Internally pre-set gas post-flow time elapses

When the remote-control pedal unit TR 52mc is used, the

machine automatically switches over to 2-step mode.

Start of cycle

Gas pre-flow time

Current rises via

upslope

End of welding, via

downslope to

crater-fill current I

E

Gas post-flow time

Pull back and hold the torch trigger

Release the torch trigger

Arc ignites with start-

arc current I

S

Welding with pre-set

main current I

H

Fig. 6 Functional sequence in 2-step mode

I

H

I

t

Loading...

Loading...