5

Important!

- It is only possible to lower the current without interrupting the

welding sequence if "Main current" is activated

- If you accidentally push forward the torch trigger in in open

circuit, no ignition will take place

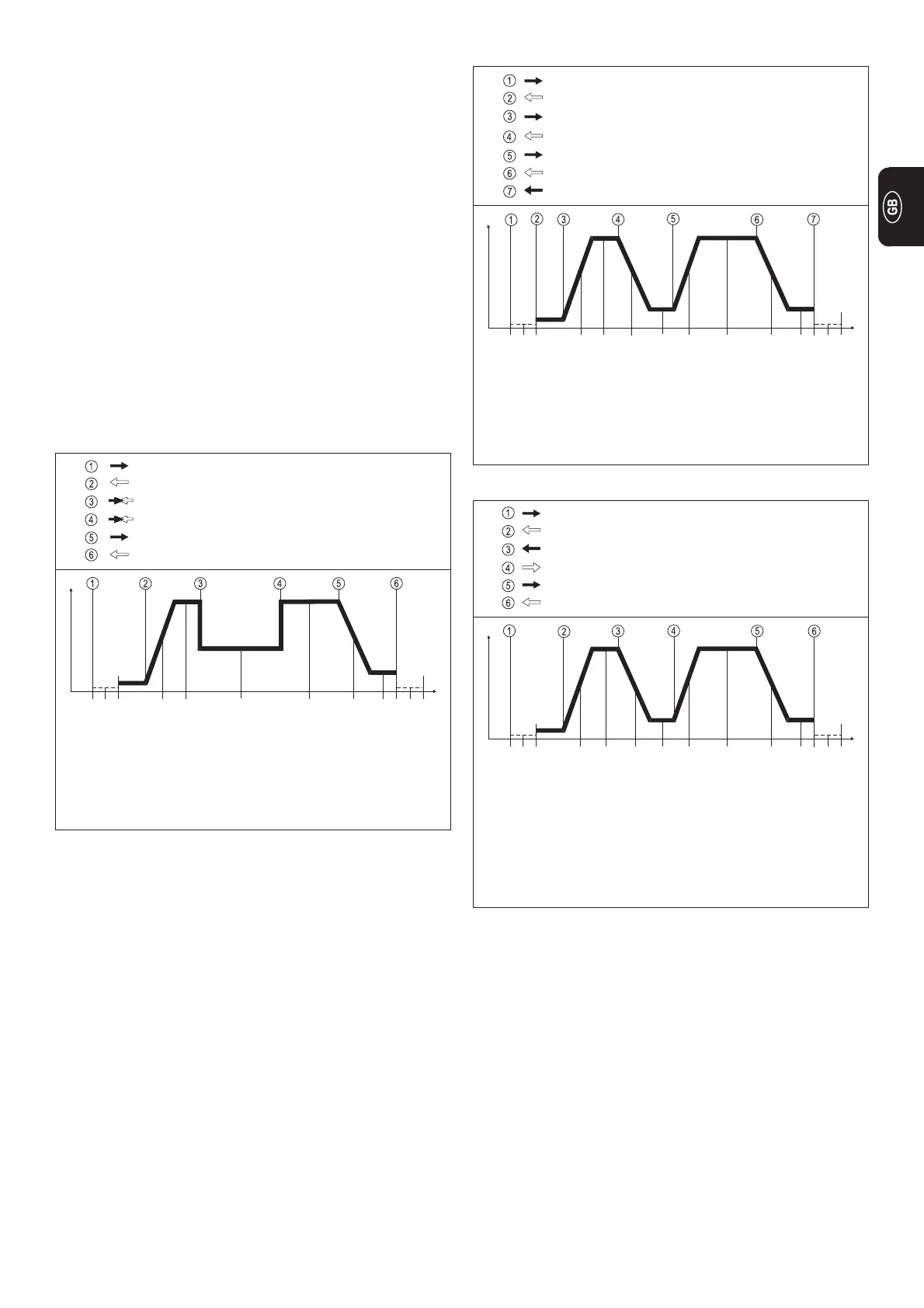

Special-4-step mode - Variant I (Fig.5)

- Makes it possible to activate the 4-step mode from TIG

torches that do not have the double-pushbutton function

- Intermediate lowering down to the reduced current I

3

(to set

this, see the section headed "Working with the program-

levels")

- Facility for lowering the welding current from the main

current to the reduced current I

3

and back, without inter-

rupting the welding sequence

- In the "PRESETTINGS LEVEL ---" program level (see "Wor-

king with the program-levels"), Parameter I3, the reduced

current I

3

can be set as a percentage of the main current I

H

- In the "PRESETTINGS LEVEL ---" program-level (see "Wor-

king with the program-levels"), parameter TIG, the setting

for SFS must be set to "1"

Special 4-step mode - Variants II / III / IV / V (Figs.5a/b/c/d)

- Makes it possible to activate the 4-step mode from TIG

torches with the double-pushbutton function

- In the "PRESETTINGS LEVEL ---" program-level (see "Wor-

king with the program-levels"), parameter TIG, the setting

for SFS must be set to

- "2" for Variant 2

- "3" for Variant 3

- "4" for Variant 4

- "5" for Variant 5

Briefly press forward the torch trigger

Briefly press forward the torch trigger

Release the torch trigger

Fig. 5 Functional sequence in special 4-step mode - Variant I

Pull back and hold the torch trigger

I

S

I

H

I

3

I

t

Pull back and hold the torch trigger

Release the torch trigger

I

E

I

H

Start of cycle

Gas pre-flow time

Current rises via

upslope

Gas post-flow time

End of welding

Welding with pre-set

reduced current I

3

(set-up)

Arc ignites with start-arc

current I

S

Welding with pre-set

main current I

H

Current drops via

downslope

Welding with pre-set

main current I

H

Crater-fill

current

Diagram showing intermediate lowering

Fig. 5a Functional sequence in special 4-step mode - Variant II

I

S

I

H

I

t

I

E

I

H

Start of cycle

Current rises via

upslope

Gas post-flow time

End of welding

Welding with pre-set

reduced current

Arc ignites with start-arc

current I

S

Welding with pre-set

main current I

H

Current drops via

downslope

Welding with pre-set

main current I

H

Crater-fill current

I

E

Current drops via

downslope

Current rises via

upslope

Pull back and hold the torch trigger

Release the torch trigger

Pull back and hold the torch trigger

Release the torch trigger

Pull back and hold the torch trigger

Release the torch trigger

Briefly press forward the torch trigger

Push forward and hold the torch trigger

Release the torch trigger

Release the torch trigger

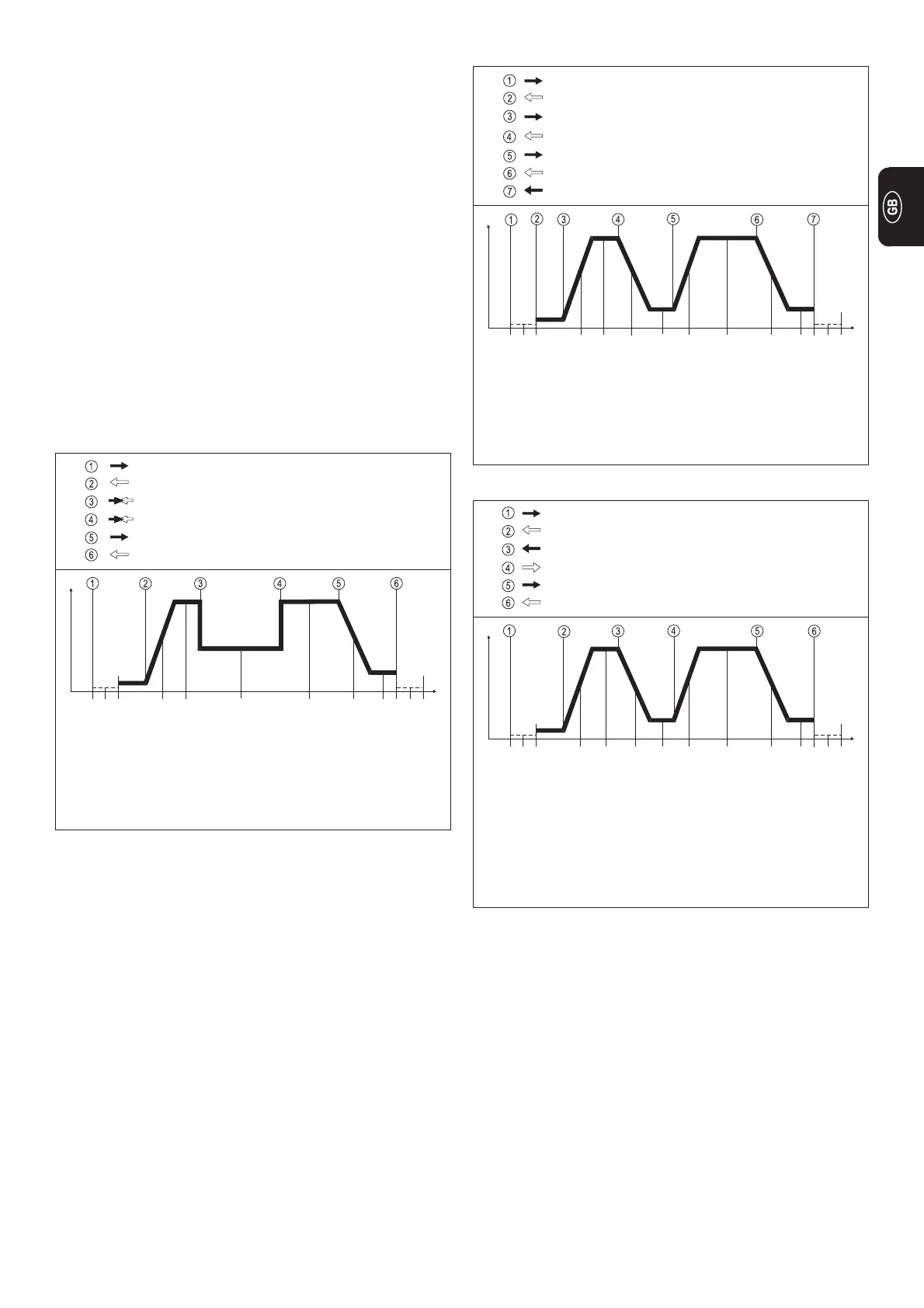

Fig. 5b Functional sequence in special 4-step mode - Variant III

Pull back and hold the torch trigger

I

S

I

H

I

E

I

t

Pull back and hold the torch trigger

Release the torch trigger

I

E

I

H

Start of cycle

Gas pre-flow time

Current rises via upslope

Current drops via

downslope

Gas post-flow time

End of welding

Crater-fill

current

Arc ignites with start-arc

current I

S

Welding with pre-set

main current I

H

Current rises via upslope

Current drops via

downslope

Welding with pre-set

main current I

H

Crater-fill

current

Diagram showing intermediate lowering

Diagram showing intermediate lowering

Gas pre-flow time

Loading...

Loading...