9

ENGLISH

OPERATING MODES

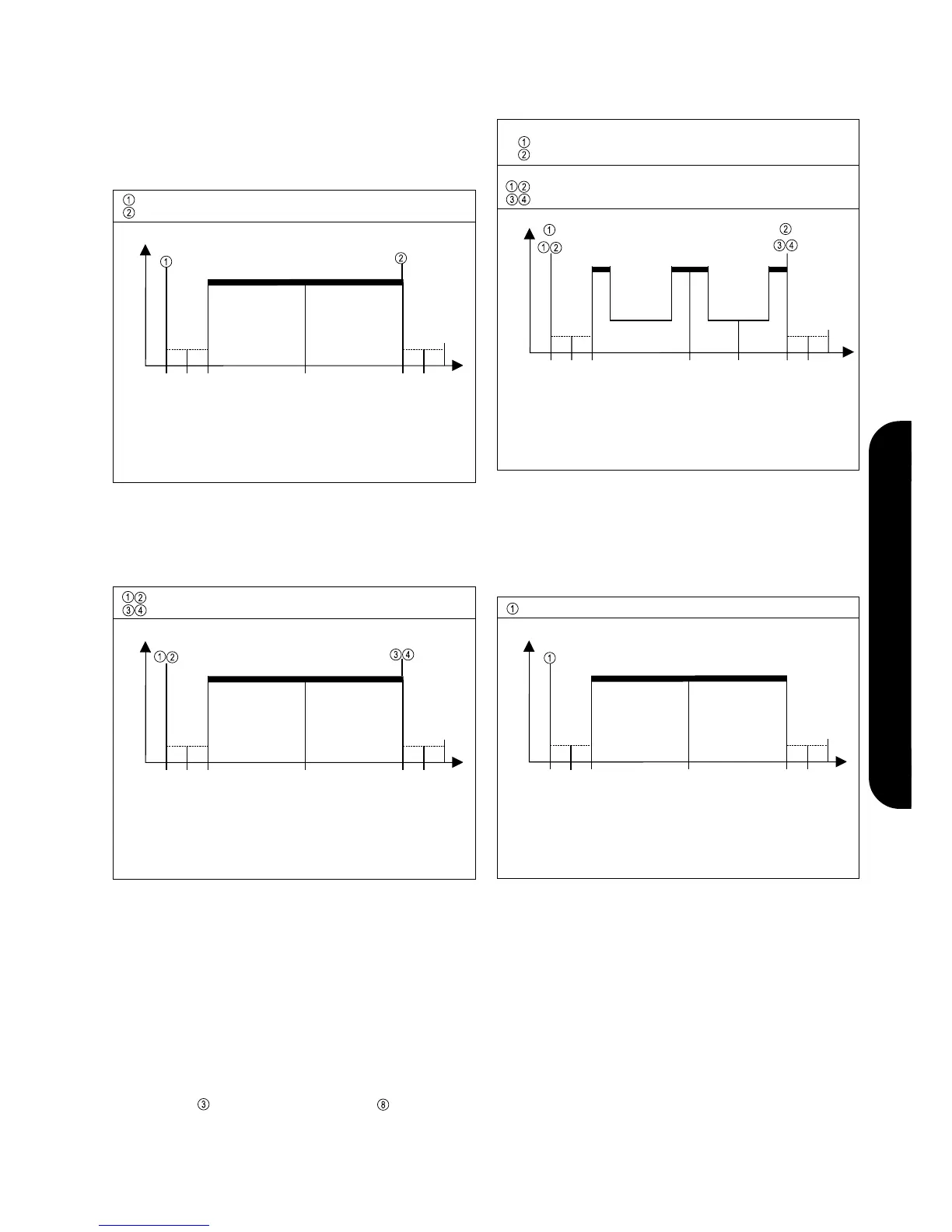

2-STEP MODE

2-step operation is often used for tacking-jobs, short weld-seams and in

automatic welding.

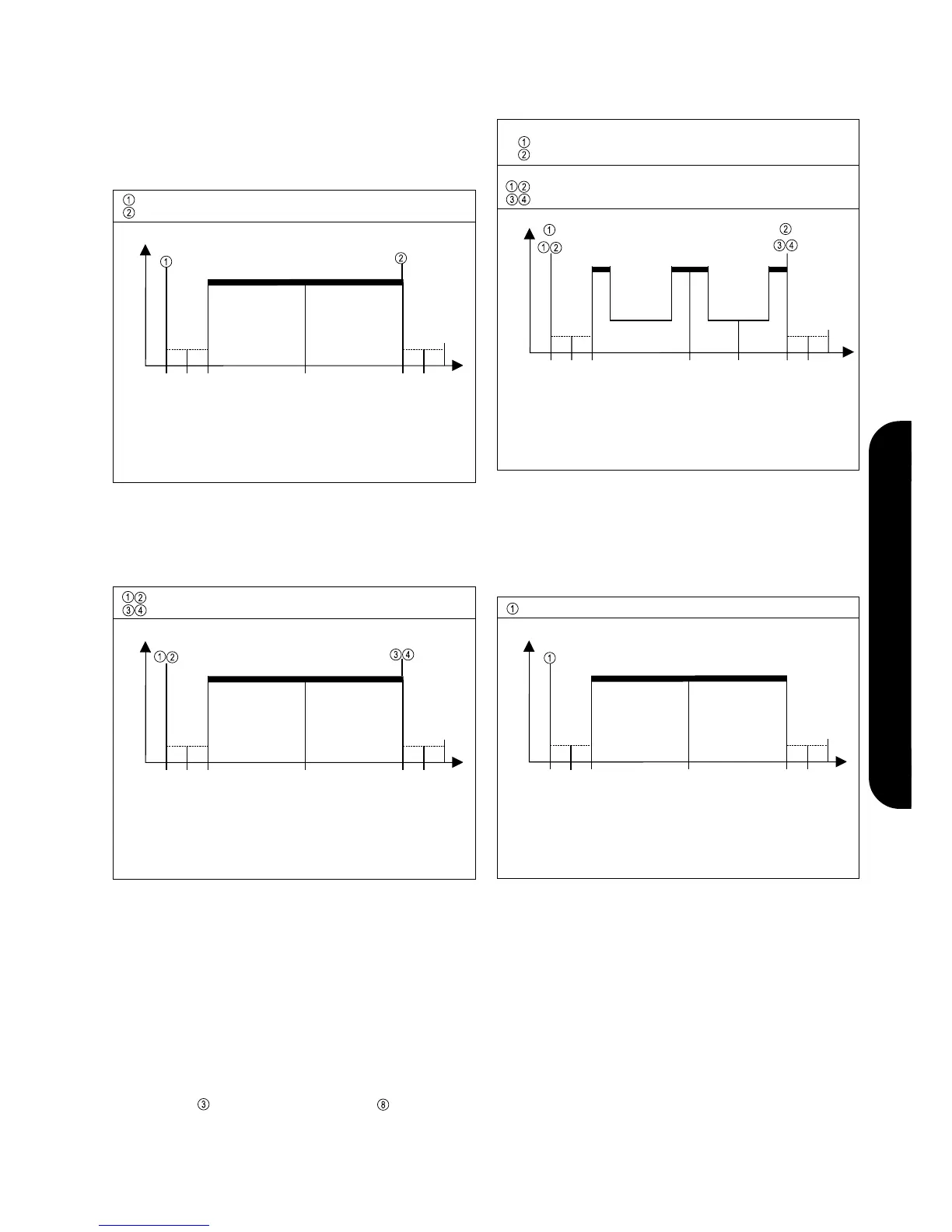

INTERMITTENT 2- / 4-STEP MODE

This operating mode is used in the light-gauge sheet field; for bridging

over air gaps.

As the welding wire is not fed continuously during the welding process,

but at adjustable intervals, the welding pool has the chance to cool down

in the intermittent pause times. This generally makes it possible to avoid

any local overheating which might cause the base metal to "burn through".

The intermittent pause times can be altered with the dials “Intermittent

welding time t1”

and “Intermittent pause time t2” .

4-STEP MODE

4-step mode is particularly suitable for longer weld seams.

Fig.9 Functional sequence in 4-step mode

t

I

Start of cycle

Gas pre-flow time

End of welding,

incl. burn-back time

Gas post-flow time

Arc ignition

= start of welding

Welding

Press and release the torch trigger

Press and release the torch trigger again

t

I

Start of cycle

Gas pre-flow time

End of welding, incl. burn-

back time

Gas post-flow time

Arc ignition

= start of welding

Intermittent

welding time

Intermittent 4-step mode

Press and release the torch trigger

Press and release the torch trigger again

Intermittent

pause time

Intermittent 2-step mode

Press and hold the torch trigger

Release the torch trigger

Fig.10 Functional sequence in intermittent 2- / 4-step mode

Fig.8 Functional sequence in 2-step mode

t

I

Start of cycle

Gas pre-flow time

End of welding,

incl. burn-back time

Gas post-flow time

Arc ignition

= start of welding

Welding

Press and hold the torch trigger

Release the torch trigger

WIRE-INCHING

In the wire-inching mode, the welding wire is fed into the torch hosepack

at the pre-set wirefeed speed, without any flow of shielding gas or current.

To stop the wire-inch:

- release the torch trigger or

- shift the mode selector switch into another position

N.B! If the operating-mode selector switch is left in the wire-inching mode

for longer than 2 min., the welding machine switches off automatically.

SPOT WELDING

Spot welding is used for welding joints on overlapped sheets that are only

accessible from one side.

Fig.11 Functional sequence in spot-welding mode

t

I

Start of cycle

Gas pre-flow time

End of spot welding,

with burn-back time

Gas post-flow time

Arc ignition = beginning

of spot-welding

Spot-welding, with

time limitation

Press and release the torch trigger

Loading...

Loading...