41

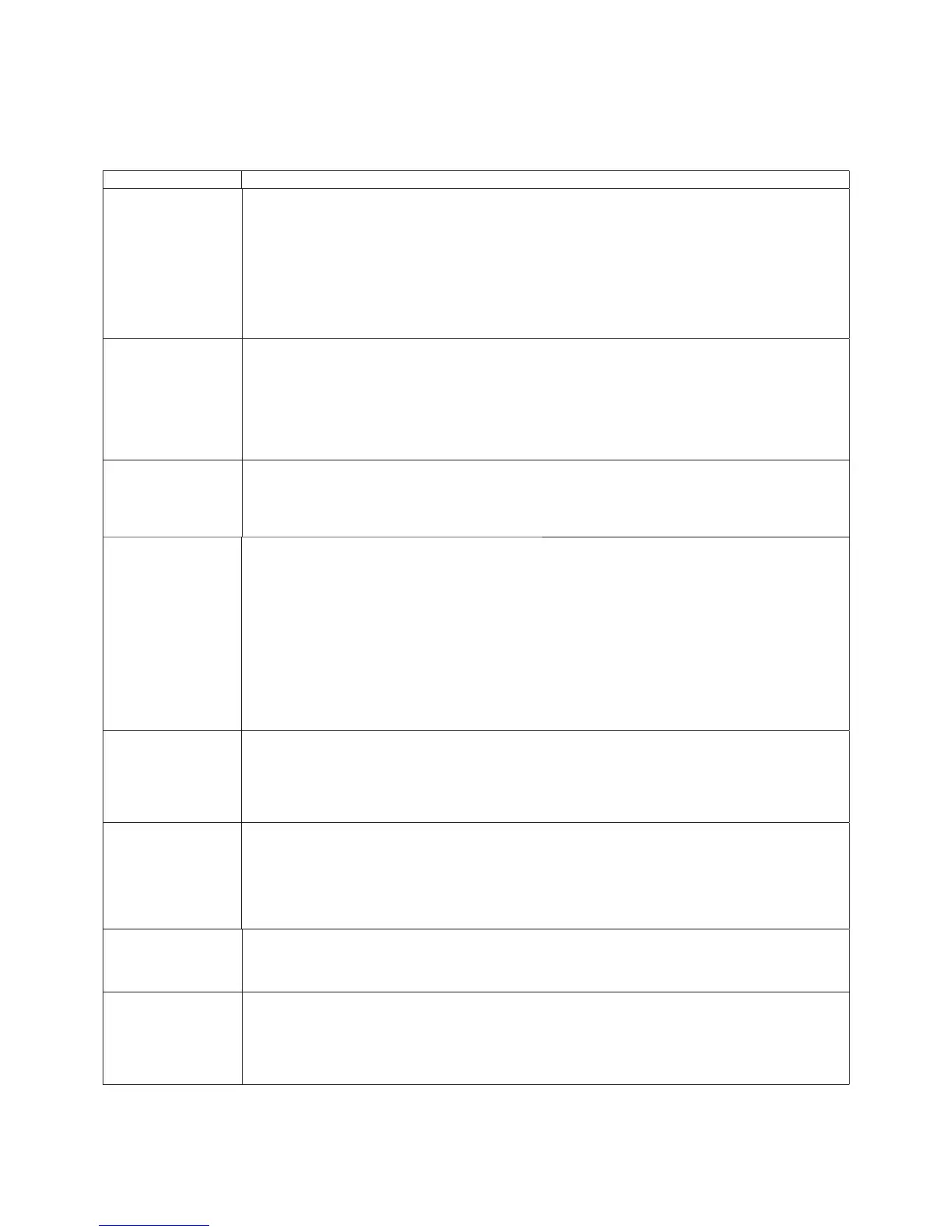

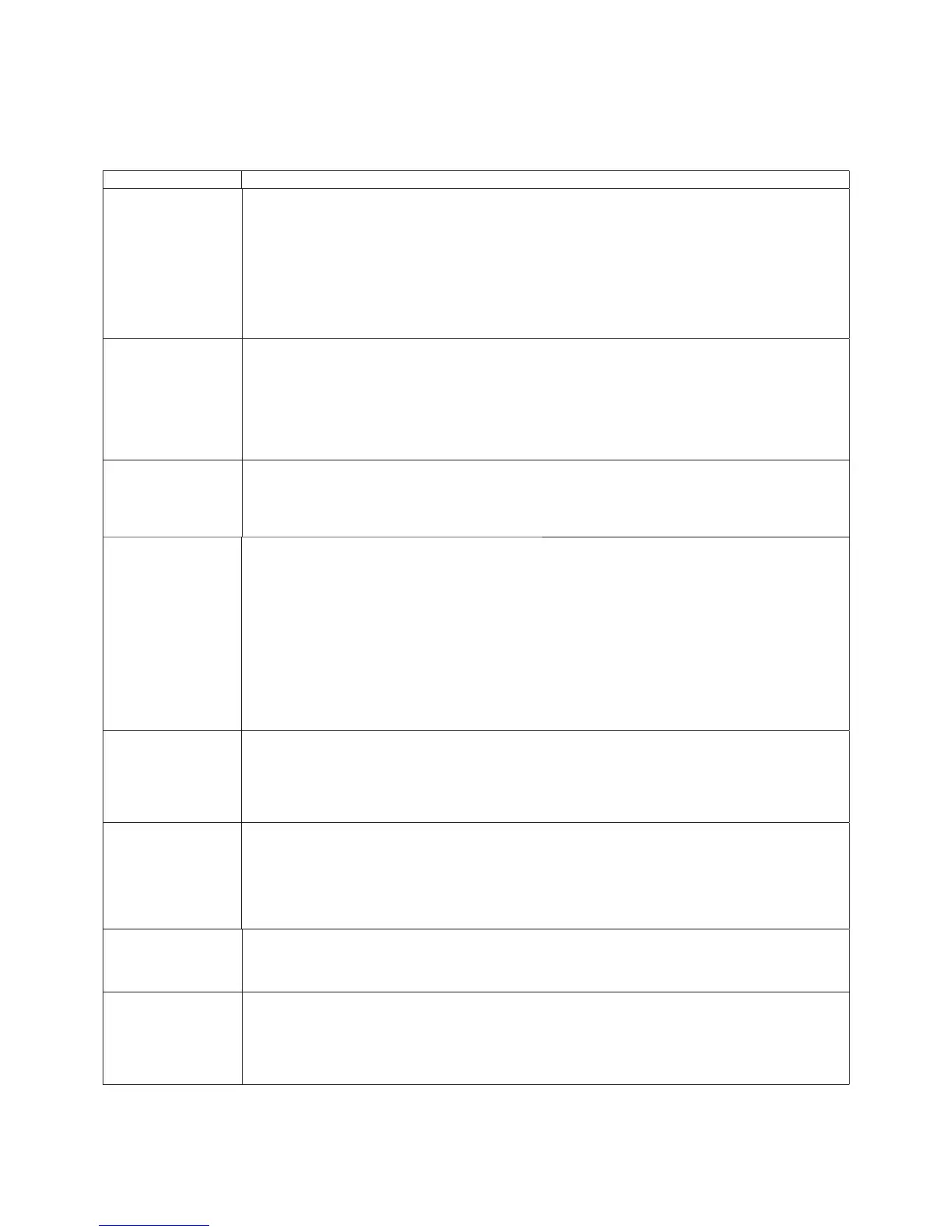

8. REMOVAL OF FAILURES AND DEFECTS

Do not execute the service operations unless You have the appropriate technical equipment and qualifi cation. The operations

mentioned below may be executed by the machine user. Other servicing operations not mentioned here but executed by the user

invalidate the guarantee. The manufacturer disclaims any responsibility for damages arisen owing to the low-quality execution

of unpermitted service operations by the user.

Failure, defect Removal

Mowing knives are

mowing unevenly

Remove the accumulated grass from bottom side of mowing mechanism.

Make sure that the knives are sharp and not deformed.

Check the tightening of knives.

Check if the mowing mechanism height setting up corresponds to the data in the chapter 6.1.11 and

6.2.4. If not, carry out the new setting up.

Check the tension of drive belts according to the chapter 7.12 and 7.14. If need be, carry out the

adjustment of tensioning.

Check the shafts of knives. If they are damaged or excessively worn out, replace them.

Check the bodies of bearings for a possible damage. With respect to the fi nding, carry out the repair or

replace them.

Unmowed stripe

remains between

rotors with knives

An unmowed stripe may remain when mowing dense grass or grass with excessively wet surface.

The travel speed shoud be adjusted to the mowing conditions by selecting the suitable gear. The

engine should run with the gas control lever in the „MAX“ position.

Check the knives if they are sharp and undamaged. If necessary, replace them.

Check the tension of drive belts according to the chapter 7.12 and 7.14. If need be, carry out the

adjustment of tensioning.

Check the bodies of bearings for a possible damage. With respect to the fi nding, carry out the repair or

replace them.

Knives of mowing

mechanism are

tearing out sods

Check the setting-up of the height of mowing, and if need be, adjust it. Sods are torn out more often

on uneven surfaces.

Check the bodies of bearings for a possible damage. With respect to the fi nding, carry out the repair or

replace them.

Check if the knives are not bent. If need be, replace them.

Drive belt of

mowing mechanism

is stopping during

operation

A damage to the mowing mechanism drive belt may occur when it jumps out of the pulley during

machine running. If it jumps out even after the check according to the following steps, it has to be

replaced.

- Check the tension of drive belt according to the chapter 7.12. If need be, carry out the adjustment of

tensioning.

- Check the belt guiding.

- Check the setting up of the height of mowing, if need be, adjust it.

- Find out if a foreign object is not obstructing the running of the belt. If it is so, remove the foreign

object.

- Check all the pulleys. Bent or cracked pulleys could cause problems. If need be, replace them.

- Check the inside surface of the pulley fi xed on the engine. If it is rough or there are cracks on it, it is

necessary to replace the pulley.

- Check the wear of tensioning mechanism components. If need be, replace the worn out components.

Drive belt of mowing

mechanism is

slipping

If the grass is too high or wet, the mowing mechanism drive belt may slip.

Check the belt for wear. If it is worn out, replace it.

Check the tension of drive belt according to the chapter 7.12. If need be, carry out the adjustment of

tensioning.

Check the tension spring of tightener of the mowing mechanism drive belt.

Replace the stretched or damaged spring.

Drive belt of mowing

mechanism is being

worn out excessively

Check all places of the belt guiding.

Find out if a foreign object is not obstructing the running of the belt. If it is so, remove the foreign

object.

Check the pulleys. If they are damaged, replace them.

Check the setting-up of the height of mowing, if need be, adjust it.

Check the tension of drive belt according to the chapter 7.12. If need be, carry out the adjustment of

tensioning.

Knives cannot be put

into motion

Check whether the belt is worn out or damaged. If it is so, replace it. If it is slack, tension it.

Check the spring of the tensioning mechanism. Replace the stretched or damaged spring.

Find out if a foreign object is not obstructing the running of the belt. If it is so, remove the foreign

object.

Knives are stopping

with delay

Check the tension of drive belt according to the chapter 7.12. If need be, carry out the adjustment of

tensioning. If it is not possible to tension the belt more due to its considerable wear, t on the new belt.

Find out if a foreign object is not obstructing the running of the belt. If it is so, remove the foreign

object.

Check the function of the electromagnetic clutch, if its disengaging is right. In case of a wrong

function let the authorized service do the replacement or repair.

Loading...

Loading...